Sorry for the delay on pictures. I got the car back together yesterday after 10 hours straight working on it. Lets begin.

BTW BMW special tools are AMAZING!!! job would have sucked by yourself or with the air controlled valve spring tool.

New seal in and valves installed.

Valve springs being pressed with the tool, it locks down so its all a one man system.

All the valve springs in. YAY!

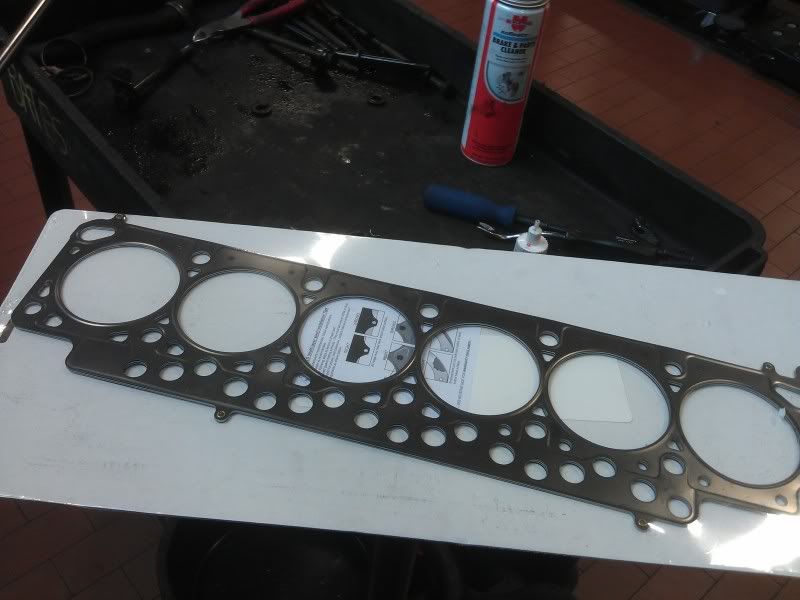

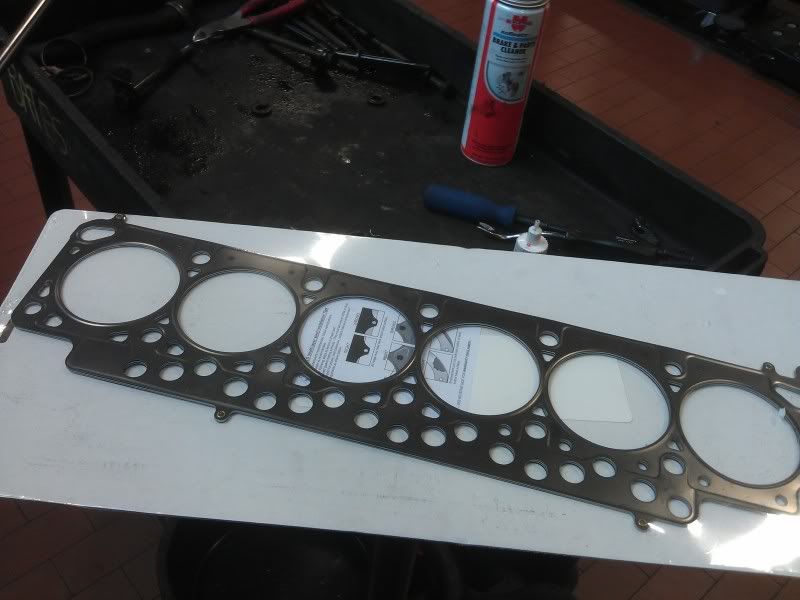

UPS FINALLY SHOWED UP, I really though they wouldnt with all my goodies to finish this up.

Got the headgasket sprayed with copper spray, I didnt have my head machined so I felt it was needed, Todd I know you said I didnt have to but Im wierd and the spray is one less thing I have to worry about.

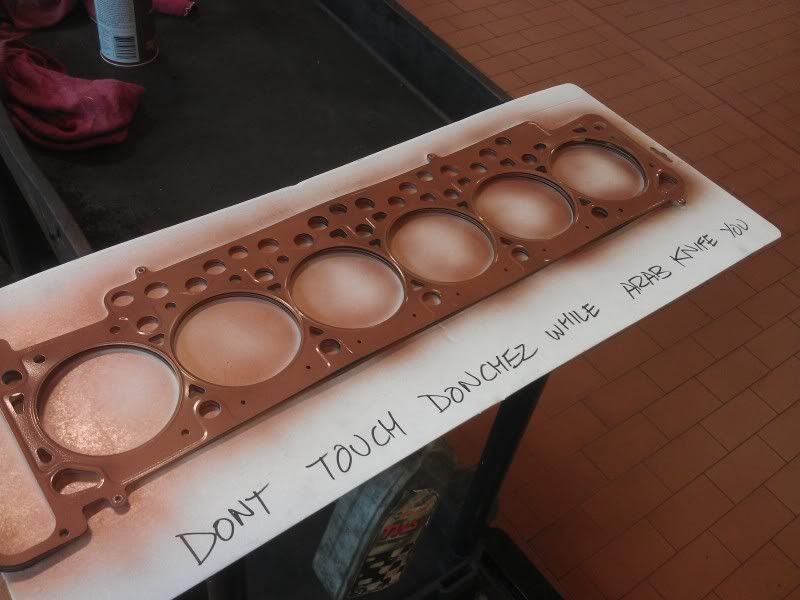

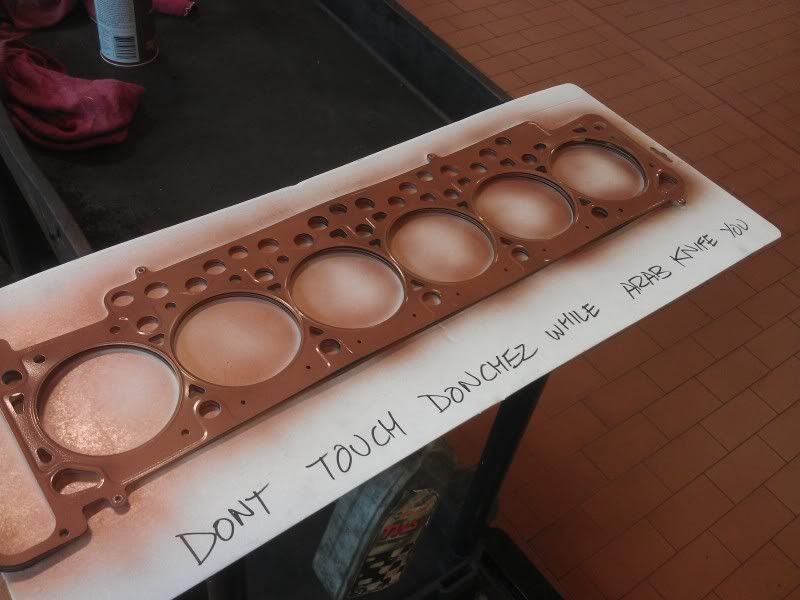

Arabic co-worker/friend to defend my headgasket while I ran to lunch and let it dry.

New rockers, shafts in and valves adjusted, I know remember why I hate rebuilding heads.To answer your Q, I didnt go with aftermarket rockers, rockers are meant to break, most common cause for a rocker failure is to tight of valves, tighter more then .012, or valve float, which is what happened to me.

Intake manifold back on with new seals, I never removed the exhaust manifold, those gaskets though me at $22 bucks a piece. fuck that.

headgasket and studs in, this is wear I fucked up, I got this all installed and then trying to put the head on it doesnt clear the firewall in the rear, I need about 2 more inches of room to make that work, even removing the rear coolant port didnt help and I wasnt about to try to installed that thing with the head install, work smart not stupid they say. ended up removing all the studs and installing the head and then reinstalled the studs with new loctite.This was the only way to do it.

I know your going to say where is the in between pictures, I didnt take them, starting going crazy a little. finished product.yay. Now I know I said that to tight valve adjust can fuck things up, and it can. After this picture I went crazy pissed, car ran like shit. found a couple of odd ends loose, fixed those. still runs like shit. Got to work today, did a leak test with the smoke machine. no leaks.Found out that I adjusted the valves with the wrong feeler gauge, a .010 gauge, the valves with the engine running couldnot be heard, NOT A GOOD THING, m30's are the loudest valve train motors, including m10 and m20 on BMW's planet of engines. This thing smoked and back fired like you couldnt believe, lucky no burnt valves from the tight valve adjust. Re-adjusted the valves to a nice .012 which is stock spec. Car runs perfect. Finally got the MS computer on it to get rid of some stumbles but other then that awesome. I was going to data log on the way home but it started snowing, no fun.

As you can see I installed a sweet oil catch can, from my early VW days. works like a charm.

Overall a easy job compared to most headgasket jobs I have done on BMW's and such, head studs definately make it easier, no angle torque. Driving the car, the new HG and studs helped but that front mount made the biggest difference. Ill have to wait and see on the dry how it does and this summer Ill have to see on the dyno what numbers I pushing out. IM me if you have any Q's.