Large manifold pressure fluctutation under boost- fixed

Large manifold pressure fluctutation under boost- fixed

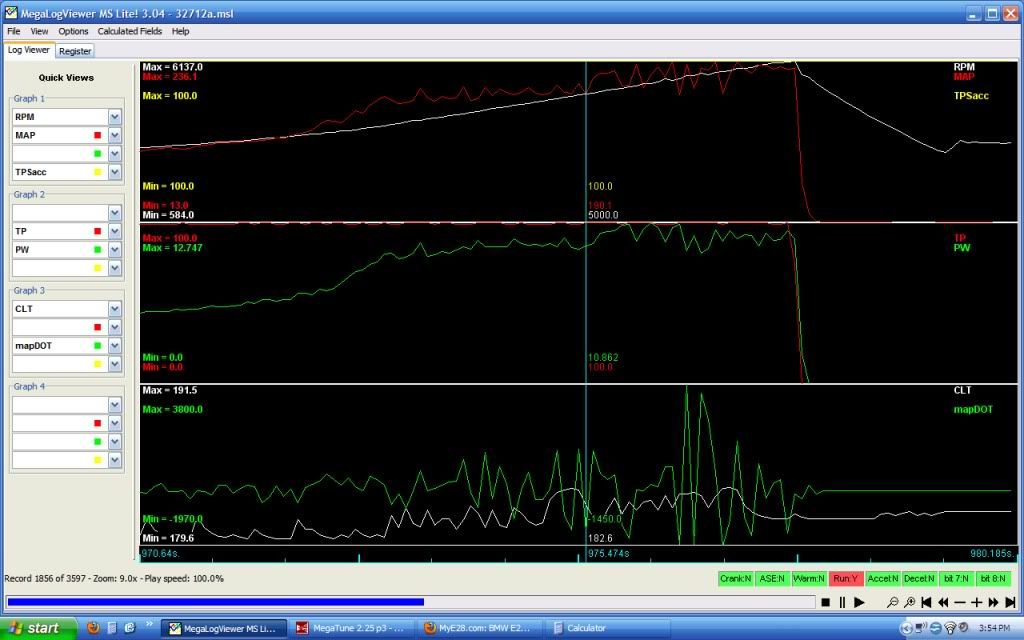

I'm running out of ideas on this one. The symptom is rather large fluctuations in MAP under boost beginning around 5200 RPM. They're most prominent in third gear as first and second just rip into the fuel cut until the car catches up. Datalogs show spikes and dips with a total magnitude of about 40 KPA. It seems to begin with boost dropping slightly, down to around 190 KPA and then jumping up to 230 within a few tenths of a second. This repeats until about 5800 RPM where it smooths back out. The last time I had a wideband on the car it showed no indication of leaning out and was actually showing a little rich through the top end.

This is running on the same MS2 hardware I have been for about four years IIRC. The injector pulsewidth is significantly affected by the swings in manifold pressure, which may amplify the problem. I don't know if its a fault with the MAP sensor itself, which behaves normally under all other conditions. I'm pretty sure its reading correctly. It reads smoothly and consistently under all other conditions. I have determined that it doesn't hold a vacuum, which may be normal as far as I know. If I pull a vacuum on the signal line the reading gradually creeps back to ambient. Same goes for pressure.

All I can imagine is that I'm having fuel supply issues at this boost pressure, but the system is identical to the one I was using on the old turbo car with the Walbro GSL 392 mounted in place of the main pump. I do not know the condition of the in tank pump, but I'm going to have a look at that at my next opportunity.

Anyone have any other ideas? Its not blowing out the spark since I've installed the MSD CDI. That hits like a fuel cut. This is a hardly noticeable lumpyness as it pulls through the 5k range. It feels great from 3500 up to 5200 before the lumpyness sets in. If anyone else drove the car I doubt they would notice, but the datalogs definitey show something going on.

This is running on the same MS2 hardware I have been for about four years IIRC. The injector pulsewidth is significantly affected by the swings in manifold pressure, which may amplify the problem. I don't know if its a fault with the MAP sensor itself, which behaves normally under all other conditions. I'm pretty sure its reading correctly. It reads smoothly and consistently under all other conditions. I have determined that it doesn't hold a vacuum, which may be normal as far as I know. If I pull a vacuum on the signal line the reading gradually creeps back to ambient. Same goes for pressure.

All I can imagine is that I'm having fuel supply issues at this boost pressure, but the system is identical to the one I was using on the old turbo car with the Walbro GSL 392 mounted in place of the main pump. I do not know the condition of the in tank pump, but I'm going to have a look at that at my next opportunity.

Anyone have any other ideas? Its not blowing out the spark since I've installed the MSD CDI. That hits like a fuel cut. This is a hardly noticeable lumpyness as it pulls through the 5k range. It feels great from 3500 up to 5200 before the lumpyness sets in. If anyone else drove the car I doubt they would notice, but the datalogs definitey show something going on.

Last edited by turbodan on Apr 15, 2012 6:34 PM, edited 1 time in total.

-

marc79euro645

- Posts: 513

- Joined: Dec 08, 2008 11:33 PM

-

marc79euro645

- Posts: 513

- Joined: Dec 08, 2008 11:33 PM

-

marc79euro645

- Posts: 513

- Joined: Dec 08, 2008 11:33 PM

Does your boost gauge concur with the datalog? if so I'm thinking wastegate.

If not, I'm thinking map sensor.

I recently saw some strange tps related ae,also seeing blowout from throttle shaft on otherside. I cleaned tps & recalibrated,seems to have solved it. My point being high boost can blow oil, etc that may have contaminated the map sensor.

Just my guesses

good luck

marc

If not, I'm thinking map sensor.

I recently saw some strange tps related ae,also seeing blowout from throttle shaft on otherside. I cleaned tps & recalibrated,seems to have solved it. My point being high boost can blow oil, etc that may have contaminated the map sensor.

Just my guesses

good luck

marc

The time it takes to go from 236 kpa down to 188 is under 8/10ths of a second. Its back up to 230 under a second later. The boost gauge doesn't respond quickly enough to show these variations. I may have to have someone drive the car so I can get a better look at it though. Can't really focus on it and drive at the same time.

-

M. Holtmeier

- Posts: 3025

- Joined: Mar 11, 2007 3:06 AM

- Location: Dallas, Texas

-

FirstFives Dictator

- Posts: 849

- Joined: Feb 12, 2006 12:00 PM

- Location: Virginia Beach, VA

- Contact:

-

FirstFives Dictator

- Posts: 849

- Joined: Feb 12, 2006 12:00 PM

- Location: Virginia Beach, VA

- Contact:

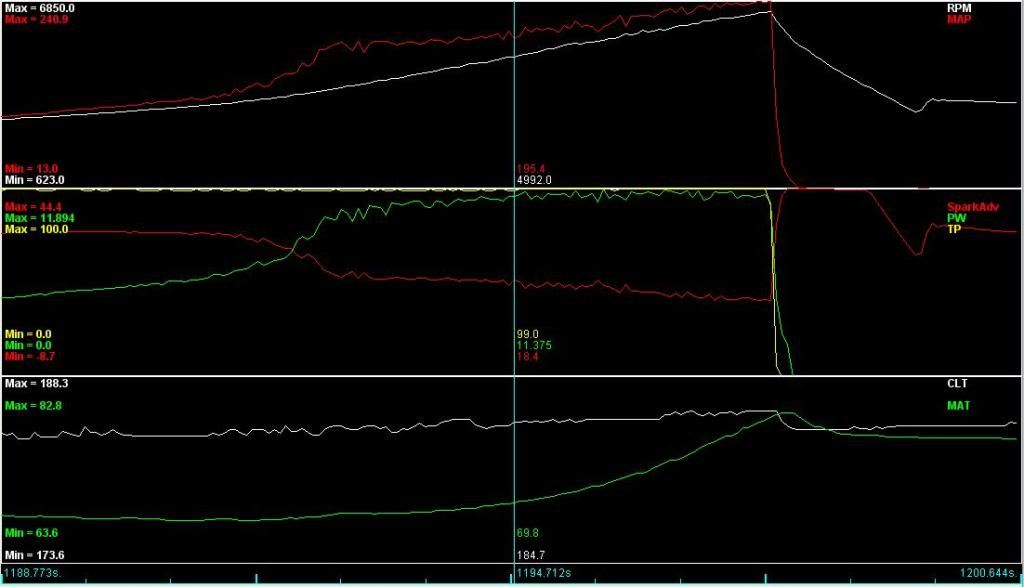

All fixed. I changed a few things:

-Swapped out one of the diverter valves, now I have two of the Bosch -114 valves.

-Swapped out the FPR with a brand new Bosch 3 bar unit I've had sitting around.

-Reinstalled the hard plastic vac line to the MS ECU that I had been running for the last three years.

-Changed the injection settings in Megasquirt to two squirts alternating from one squirt simultaneous.

I don't know if it was having fuel pressure issues since I don't have a way to monitor that, but I figured I should configure the system to minimize pressure/flow fluctuation. The FPR was of undetermined age and the signal line smelled of fuel, so that was due. The simultaneous injection must have been generating some substantial pressure fluctuation which must have some effect. I don't know if that was the problem but I like it better with two banks of three injectors firing alternately than it was with all six 57lb/hr injectors popping open at once. Seems like it could result in a substantial oscillation if the FPR wasn't able to respond quickly enough. It would also stand to reason that this would be hard on the FPR and could cause premature failure.

Its very smooth now and it pulls hard. Depending on the condition of the road its right on the edge of traction in third gear. You can see little bumps in the RPM plot as the wheels momentarily lose traction. I'm very happy with that since its only running about 1 bar. I used to hit ~1.45 with the old motor and B25 cam and it never scratched for traction like this.

-

M. Holtmeier

- Posts: 3025

- Joined: Mar 11, 2007 3:06 AM

- Location: Dallas, Texas