Nebraska_e28 wrote:Very interesting. Can you comment on how this setup performed compared to a log mani or even divided (or non-divided) tube mani? I always wondered why 666fab produced an adapter of this style for the m20 & not the m30.

I'll try not to derail this discussion too much...

I cannot comment on how it performed. Like a lot of fabrication projects, I never got in on a running car. I gave the manifolds and adapter to Paul when he bought my e34 last July. It still needed a little bit of welding but maybe someday he'll put it to use.

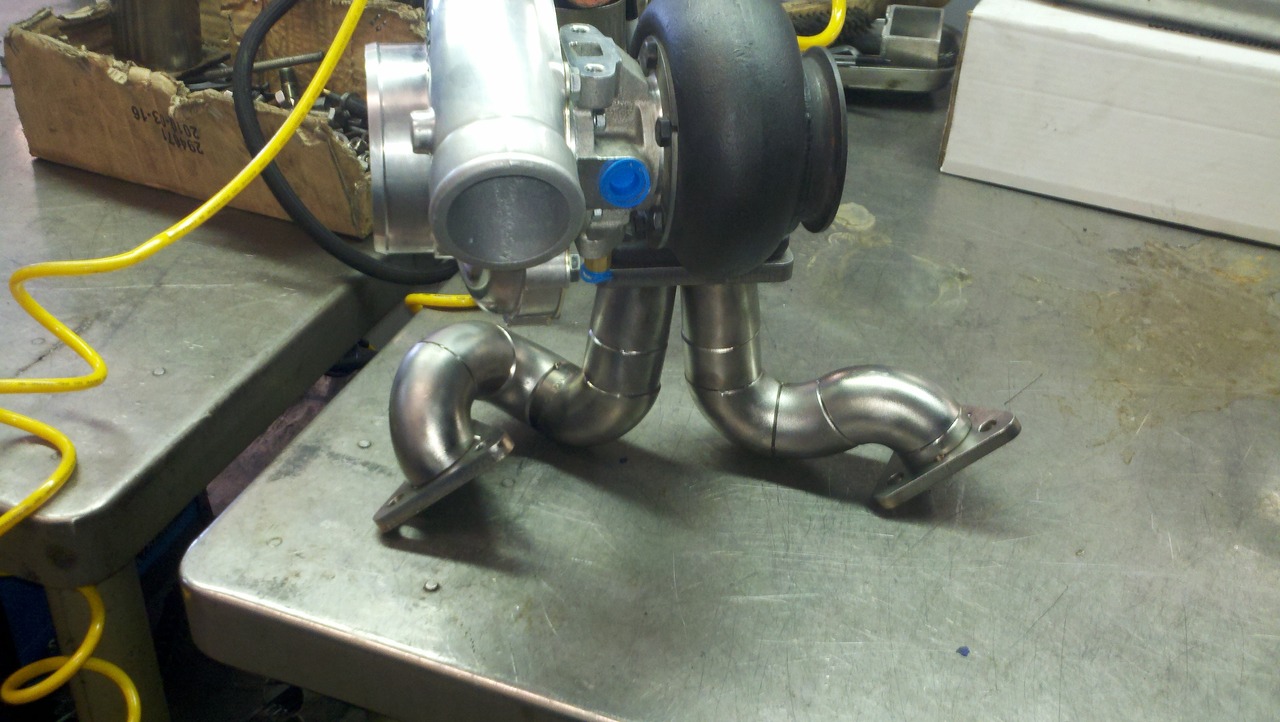

All things being equal (engine, tune, equivalent turbine A/R...), a divided, twin scroll set-up will provide earlier spool. The question is how much earlier and sadly I never got to find out. If you look at that top picture that was a COMP turbo GT4094 equivalent. I think that turbo was rated for something like 800+HP. Totally unnecessary but it would have been fun. I think for most builds a log manifold works just fine. A best guess would be that 500whp (on pump gas) is about the limit of what most logs will produce with the right sized turbo(TCD, Cartech, 745i,...). I would think that EGT and pre-turbine manifold pressure will start to creep up too high due to the style of runner flow. There is quite a bit of energy to disperse.

I would think that 666 made adapters for the M20 and not the M30 partly because of demand but also because of the b34/b35 manifold differences as illustrated previously. There are lot more dudes trying to turbo e30s than e28's/e24s/e23s...

My only fear with this set-up would be the tubing cracking without the turbo being supported by additional bracing. Thats a lot of tubing/piping supporting an HX50. Also, wheres the wastegate?

I found a couple of pictures of the porting on the b34 manifolds: