Turbo ETA build

Re: Turbo ETA build

I dropped a cylinder head off at the machine shop today. Bought on ebay as a good used head, came in with the usual wiped out cam/rockers and a decent gouge in the mating surface, precisely where the metal rings of the head gasket seal around the combustion chamber of cylinder number 6. I think it should be alright with a slight resurfacing.

It will be going together with a Catcams turbo conversion cam. More lift and duration on the intake side, wider lobe center on the exhaust side. I ran this exact cam before on the original build but ended up going back to the B25 cam for reasons I cannot remember. I think the power felt flatter through the midrange with this cam, which is actually a good thing at high boost. Spreads the BMEP out a bit and helps avoid excessive cylinder pressure in the typical det zone between 4000 and 5000 RPM. In any case, it's going in. When that head is done I'll pull the original super eta head off that's in the car now and slap on the new one with that cam and B25 valve springs.

For now I turned the boost back down to where the clutch can hold it. I don't need to run 1 bar right now, I can turn it down until I feel like buying a clutch that can handle it. I think I'm finally mature enough to be okay with that, at 37 years old. I may leave this one be with the small turbo and low boost, it's still plenty fast and fun to drive. Will be even better with a proper cam and a broad powerband.

It will be going together with a Catcams turbo conversion cam. More lift and duration on the intake side, wider lobe center on the exhaust side. I ran this exact cam before on the original build but ended up going back to the B25 cam for reasons I cannot remember. I think the power felt flatter through the midrange with this cam, which is actually a good thing at high boost. Spreads the BMEP out a bit and helps avoid excessive cylinder pressure in the typical det zone between 4000 and 5000 RPM. In any case, it's going in. When that head is done I'll pull the original super eta head off that's in the car now and slap on the new one with that cam and B25 valve springs.

For now I turned the boost back down to where the clutch can hold it. I don't need to run 1 bar right now, I can turn it down until I feel like buying a clutch that can handle it. I think I'm finally mature enough to be okay with that, at 37 years old. I may leave this one be with the small turbo and low boost, it's still plenty fast and fun to drive. Will be even better with a proper cam and a broad powerband.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

Sounds like a good plan! Awaiting results.

Re: Turbo ETA build

The head is built and installed. Waiting on a sintered intermediate shaft pulley to replace the shitty stamped steel original. I may order another set of head bolts, I was going through the torque process when I realized I wasn't really paying attention to the sequence like I should. May or may not have missed an angle torque at some point. No way to know, though after the fact I realized I should have marked all of the bolts after the initial 22 ft-lbs to keep track of each step. There are two angle torque steps so a little paint mark on the bolt head at 12 o clock before those steps would make it perfectly clear where each was in the process. Would be another $25 for a set of bolts, and if I pay attention this time I would have peace of mind.

That's the downside of working all day without a lunch break. The mind wanders. It is getting close though.

That's the downside of working all day without a lunch break. The mind wanders. It is getting close though.

Re: Turbo ETA build

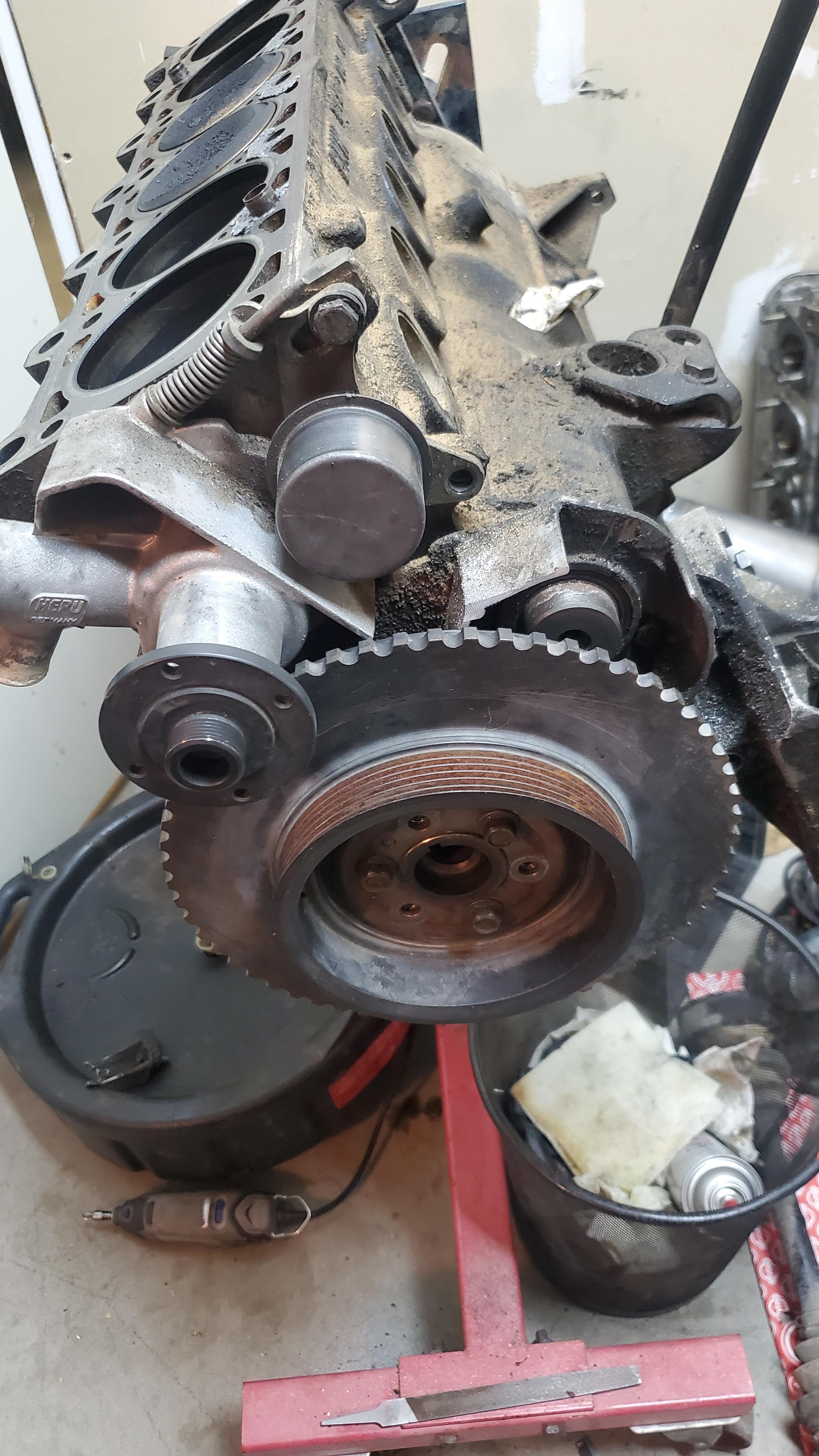

The missing piece has arrived:

I had forgotten to order the improved intermediate shaft pulley. This 2.7 still had the stamped steel pulley, not even the reinforced version but the early single sheet design. Cant be raising the rev limit with that in there.

Looks the same from here, though I cleaned the valve cover and timing covers. No external signs of the improvements:

It runs good. Going back to tuning, the effect the cam has on the tables is dramatic. I did spool it up one time on the test drive and I was very surprised how it pulled for only 140kpa. That's minimum boost, around 8 psi. Very stout, and the broader torque curve is quite evident.

I rearranged the ignition map to fit the expected VE curve so that should be about right. I winged it on the fuel table and then I ended up pulling a bunch more out in the sub 3500 rpm range. The daily driver zone was super rich. Makes sense, that was where the eta cam was efficient.

In conclusion, don't even bother boosting the eta cam. Even un-tuned this thing runs so much better. Sounds pissed revving out under boost too. The exhaust note is markedly different. It is a total transformation.

I had forgotten to order the improved intermediate shaft pulley. This 2.7 still had the stamped steel pulley, not even the reinforced version but the early single sheet design. Cant be raising the rev limit with that in there.

Looks the same from here, though I cleaned the valve cover and timing covers. No external signs of the improvements:

It runs good. Going back to tuning, the effect the cam has on the tables is dramatic. I did spool it up one time on the test drive and I was very surprised how it pulled for only 140kpa. That's minimum boost, around 8 psi. Very stout, and the broader torque curve is quite evident.

I rearranged the ignition map to fit the expected VE curve so that should be about right. I winged it on the fuel table and then I ended up pulling a bunch more out in the sub 3500 rpm range. The daily driver zone was super rich. Makes sense, that was where the eta cam was efficient.

In conclusion, don't even bother boosting the eta cam. Even un-tuned this thing runs so much better. Sounds pissed revving out under boost too. The exhaust note is markedly different. It is a total transformation.

Re: Turbo ETA build

Also wanted to note that the valve cover can be removed and it looks like the spark plugs can even be serviced without removing the turbo with the US spec 524td manifold. The key is the riser between the manifold and turbine, that extra two inches sets it up in a very good spot.

I always hated that about the old setup with the european non-AGR manifold. It doesn't protrude out far enough to provide clearance even with a spacer between the manifold and turbine.

I always hated that about the old setup with the european non-AGR manifold. It doesn't protrude out far enough to provide clearance even with a spacer between the manifold and turbine.

Re: Turbo ETA build

This evening I had the opportunity to square off with a WRX, found out after the fact that it was a 2017. We opened it up from 40 mph and I gave him the jump. We started out pretty even but by the top of second gear I was reeling him in. Same story in third, again pulling on this WRX on the top end. If we had more room I would have officially walked by this guy, but no need really. The gap was closing and I was a little faster.

He said it was stock so it's a good benchmark. Google says these things dyno about 225 at the wheels and run a high 13 second 1/4. This squares up perfectly with the boost level I'm running and my past experience. The car really feels healthy, this is a good power level for an e28 and compromises nothing on longevity or reliability. More power than an e28 M5 with better mileage and less maintenance, with quite a bit more in reserve if desired.

That said, I will be pulling the engine out quite soon. It had always been prone to fouling the plugs on #4 and #5, and the oil consumption has been excessive. I was hoping this was valve seals and perhaps the new head would help alleviate this. Upon pulling the head I was disheartened to see significant scoring inside the suspect cylinders. Always optimistic, I put the head on anyway just to see what happens. The increased rev limit has resulted in a disproportionate increase in oil consumption and the same old plugs are coming out black and oily. If I'm lucky, this is the last surprise this e28 has in store for me.

The new plan of action is to dunk in the engine that was originally intended for the 524, it's sitting here with a brand new valvetrain essentially ready to go. I'll either get another block and swap this super ETA stuff into it with fresh rings or just slap the fresh head on a complete B25 bottom end. I need the car sorted by the end of the month, this will be my daily again for at least a little while.

He said it was stock so it's a good benchmark. Google says these things dyno about 225 at the wheels and run a high 13 second 1/4. This squares up perfectly with the boost level I'm running and my past experience. The car really feels healthy, this is a good power level for an e28 and compromises nothing on longevity or reliability. More power than an e28 M5 with better mileage and less maintenance, with quite a bit more in reserve if desired.

That said, I will be pulling the engine out quite soon. It had always been prone to fouling the plugs on #4 and #5, and the oil consumption has been excessive. I was hoping this was valve seals and perhaps the new head would help alleviate this. Upon pulling the head I was disheartened to see significant scoring inside the suspect cylinders. Always optimistic, I put the head on anyway just to see what happens. The increased rev limit has resulted in a disproportionate increase in oil consumption and the same old plugs are coming out black and oily. If I'm lucky, this is the last surprise this e28 has in store for me.

The new plan of action is to dunk in the engine that was originally intended for the 524, it's sitting here with a brand new valvetrain essentially ready to go. I'll either get another block and swap this super ETA stuff into it with fresh rings or just slap the fresh head on a complete B25 bottom end. I need the car sorted by the end of the month, this will be my daily again for at least a little while.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

Funny I was just about to ask if there have been any unsuspecting victims.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

Current highway mpg?

Re: Turbo ETA build

Odometer is inop but I did make a run out to Estancia yesterday, a little over 140 miles round trip. Starting with a full tank, I returned home with 3/4 showing on the gauge. My estimate is that this is high 20's. I have seen 27 before with the last car on a similar trip and this one may be doing even better since I've been really working to get the fuel map to 14.7 under cruising. The M20 with a tall final drive ratio is a sure thing for good MPG.

I got tired of this pile of front end stuff on my floor so I reinstalled the valance, bumper trim and grilles. Looks nice again, weathered and old but nice. The valance only required minor trimming in the middle section to fit and it clears the intake plumbing easily.

I hate to see those oil drops but the rear main has yet to be addressed. I've been having a hell of a time getting the front of the motor sealed up too. The head I just took off had a new cam seal and carrier o-ring as well as new rocker shaft cutout plugs and a new valve cover gasket. It was still leaking. This new head with all new seals and gaskets is leaking even worse. I used to be able to get these to seal up without silicone but I'll tell you what, next one is going to be absolutely glued together.

I got tired of this pile of front end stuff on my floor so I reinstalled the valance, bumper trim and grilles. Looks nice again, weathered and old but nice. The valance only required minor trimming in the middle section to fit and it clears the intake plumbing easily.

I hate to see those oil drops but the rear main has yet to be addressed. I've been having a hell of a time getting the front of the motor sealed up too. The head I just took off had a new cam seal and carrier o-ring as well as new rocker shaft cutout plugs and a new valve cover gasket. It was still leaking. This new head with all new seals and gaskets is leaking even worse. I used to be able to get these to seal up without silicone but I'll tell you what, next one is going to be absolutely glued together.

Re: Turbo ETA build

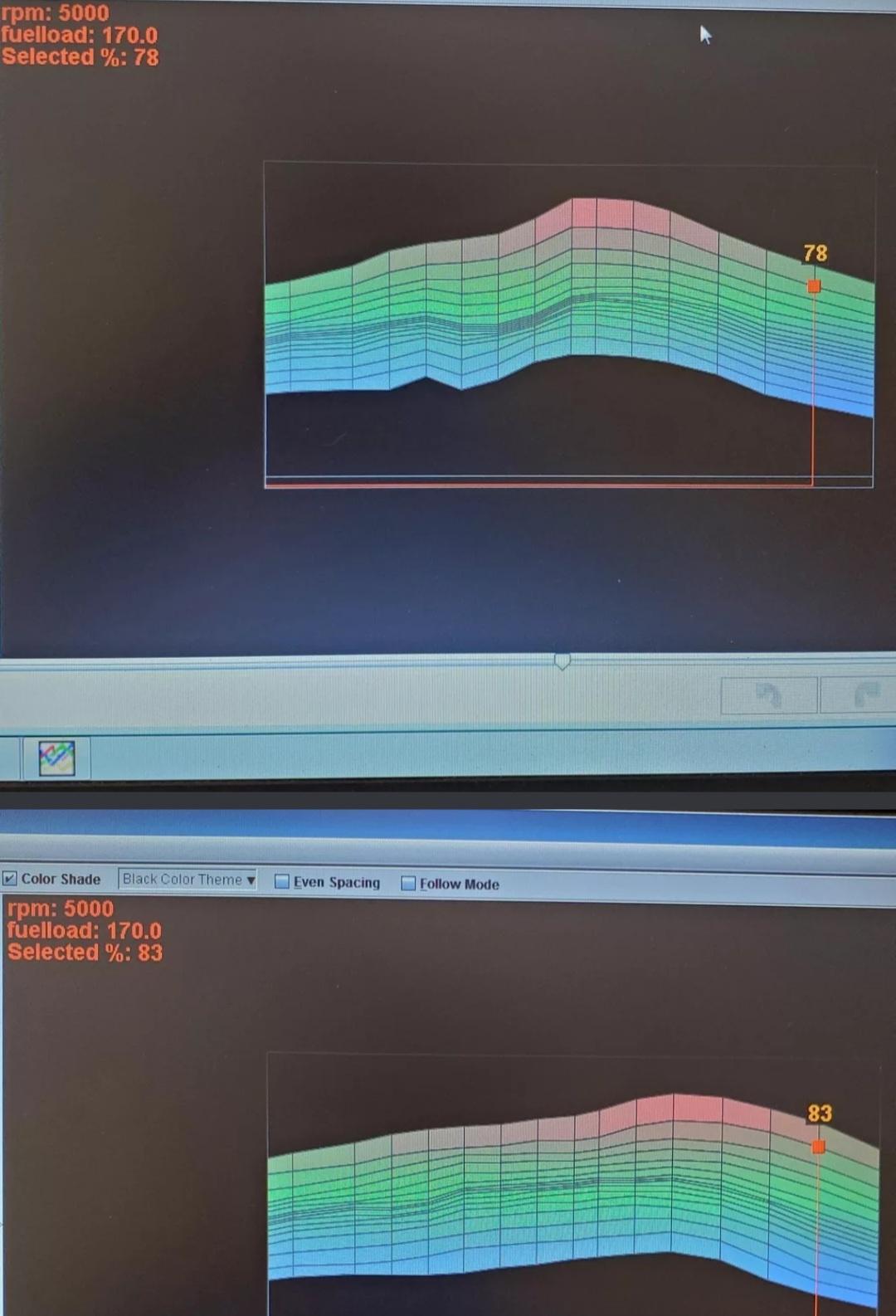

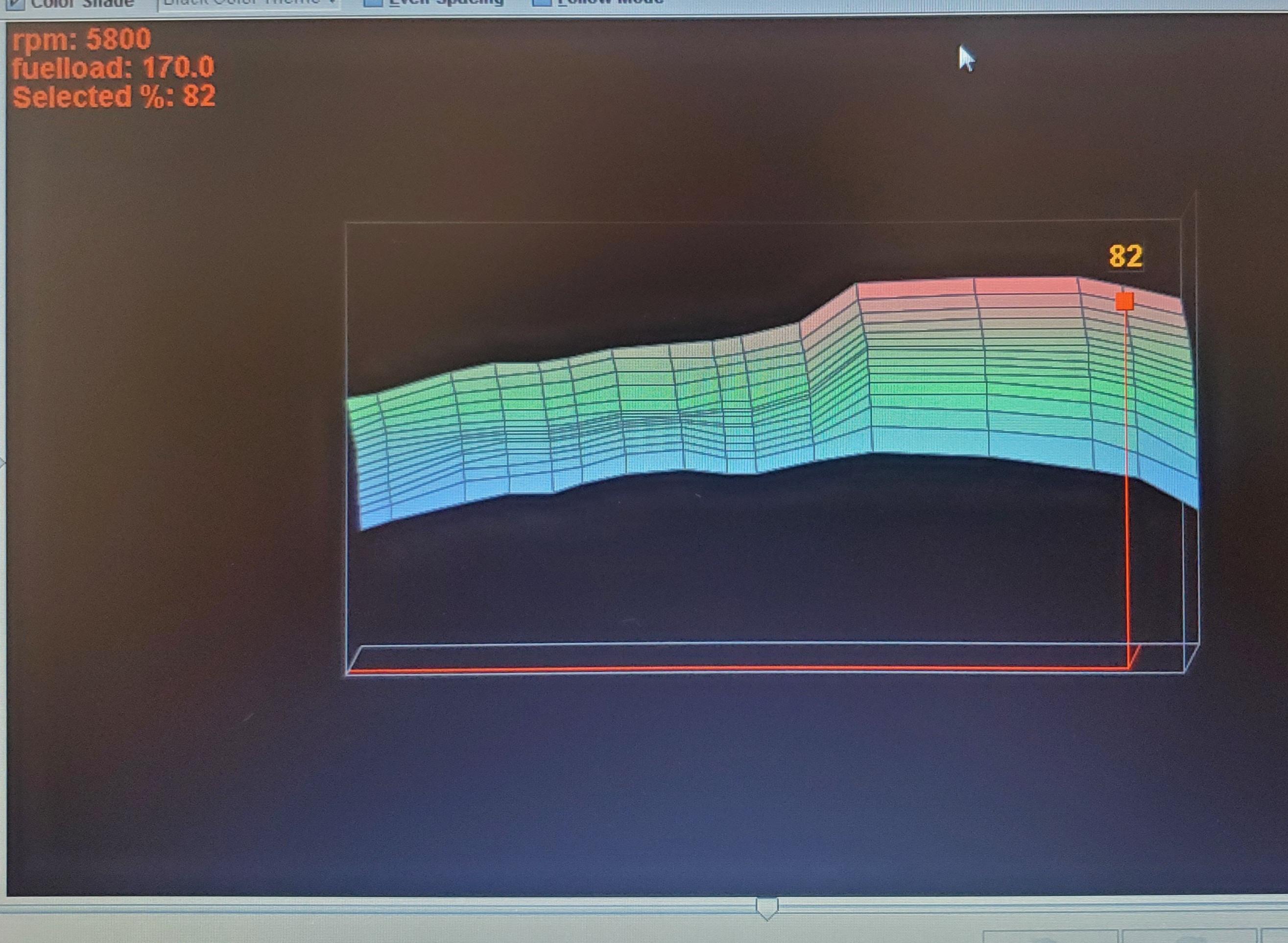

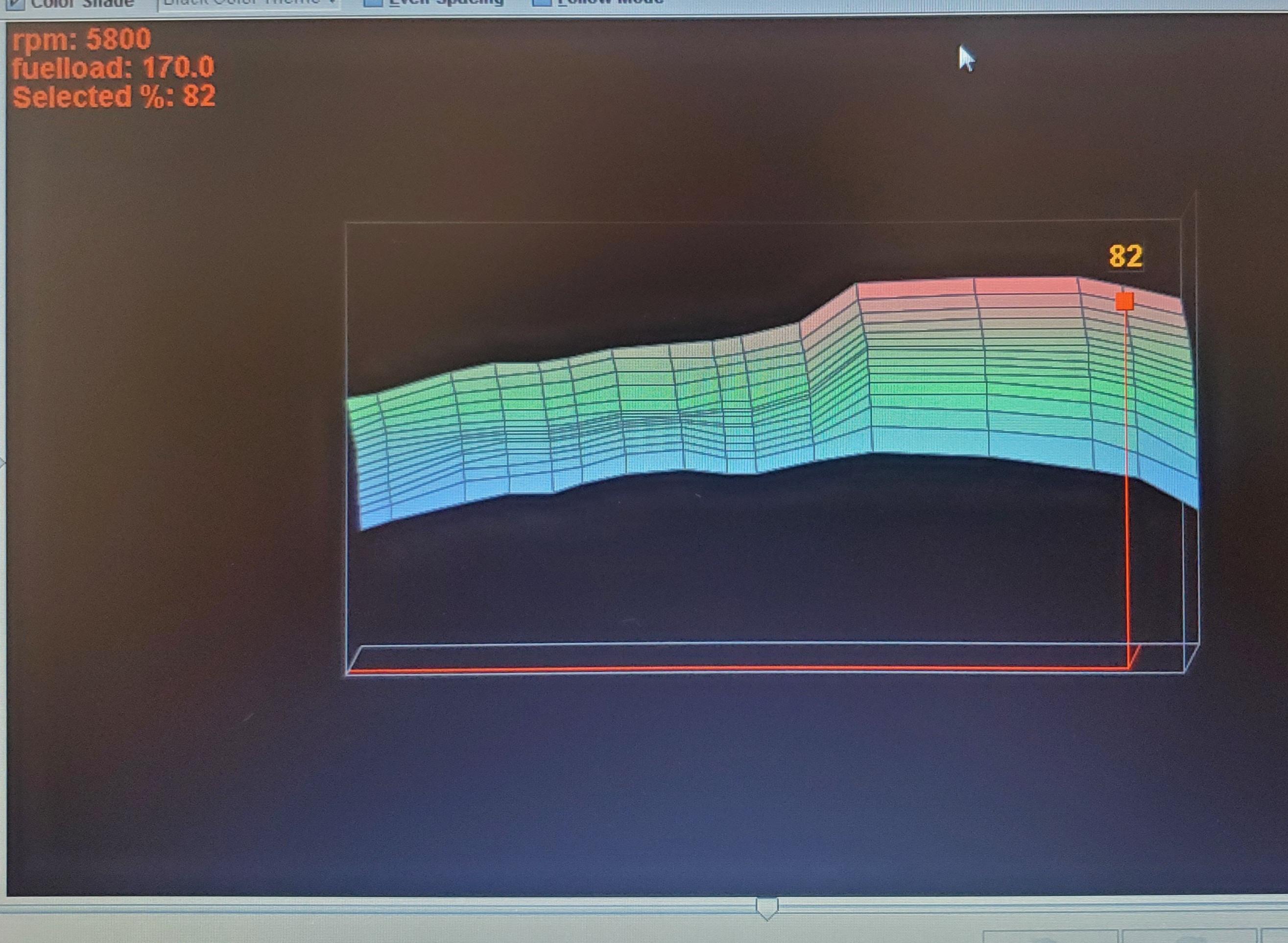

Revisiting fuel maps since the new cam went in. Here we have the stock B27, then the B27 with the B25 intake:

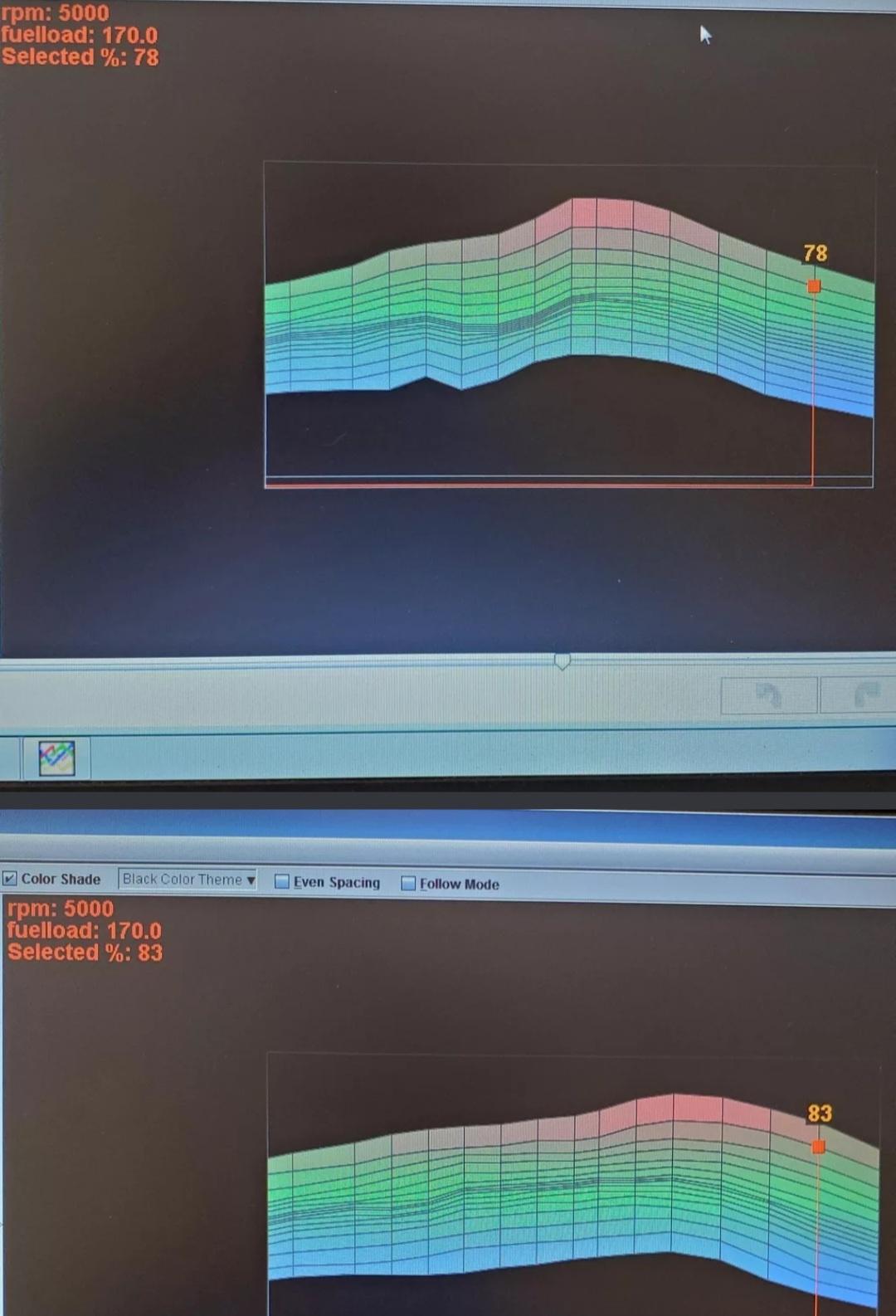

And now the catcams turbo cam with the B25 intake:

Similar VE at 5800 RPM as the B25 intake with the B27 cam at 5000 RPM. The breadth of that torque curve is evident and the top end pull is excellent. Low-mid power isn't bad either, it's certainly sleepier than it was with the B27 cam but dipping into the throttle even partially still starts making boost without delay.

I don't know why I took this cam out of the last build. I have no complaints about the power delivery.

And now the catcams turbo cam with the B25 intake:

Similar VE at 5800 RPM as the B25 intake with the B27 cam at 5000 RPM. The breadth of that torque curve is evident and the top end pull is excellent. Low-mid power isn't bad either, it's certainly sleepier than it was with the B27 cam but dipping into the throttle even partially still starts making boost without delay.

I don't know why I took this cam out of the last build. I have no complaints about the power delivery.

Re: Turbo ETA build

Spent about four hours pulling the motor today. Not a record time by any stretch. Pretty filthy too with the rear main leak. That shit went everywhere.

I may get the other motor in tomorrow if I'm feeling spunky. The prospect of fixing oil leaks and resolving the oil consumption is enticing. I certainly hope this other motor is good, I never took the head off so it's a bit of a gamble. The plugs that came out looked good so I feel pretty confident.

I may get the other motor in tomorrow if I'm feeling spunky. The prospect of fixing oil leaks and resolving the oil consumption is enticing. I certainly hope this other motor is good, I never took the head off so it's a bit of a gamble. The plugs that came out looked good so I feel pretty confident.

Re: Turbo ETA build

What a day. Got the motor and trans back in. I used a spare clutch I had on the parts pile from around 2009, a very low mile stock M20 unit. Looked great, far better than the crispy critter I took out. I had ordered a clutch from "gripforce" and they sent me about half of what I ordered, then upon my inquiry they informed me that the disc was on backorder and would not be here any time soon. Waste of time and a disappointment but at least I had the spare unit to get going in the meantime.

The new motor does run but it's not quite happy. It doesn't make as much vacuum as the turbo cam in the motor I just pulled or the original cam used to. Idle quality is not great even though this tune worked very well with the various configurations on the old motor. This motor was a gamble and I'm a little worried about it.

Above idle it smooths out well, which is the point I discovered the other issue. This very nice looking clutch I put in slips badly at the same boost level the crispy critter was holding. Clutch pedal effort is also significantly less than it used to be so I'm wondering if the pressure plate has somehow gone soft. Exact same part number as what came out, should have been the same part just in better condition.

I will be pulling the trans again to put in a proper clutch from someplace that actually has one in stock. I'll try to get the engine to run better with some tuning, though this cam is in between the turbo cam I just put in the other motor and the stock eta cam. If everything with the motor were good to go it would just need some tuning on the fuel map but I fear it may have some valve sealing issues indicated by the poor idle vacuum. If the bottom end seems good and it's not using oil perhaps I'll pull the head and swap it out with the other one with the turbo cam.

I never used to have these sorts of problems. I used to build motors from a bare block and leave nothing to chance. Something to be said for that. This shit is wearing me out.

The new motor does run but it's not quite happy. It doesn't make as much vacuum as the turbo cam in the motor I just pulled or the original cam used to. Idle quality is not great even though this tune worked very well with the various configurations on the old motor. This motor was a gamble and I'm a little worried about it.

Above idle it smooths out well, which is the point I discovered the other issue. This very nice looking clutch I put in slips badly at the same boost level the crispy critter was holding. Clutch pedal effort is also significantly less than it used to be so I'm wondering if the pressure plate has somehow gone soft. Exact same part number as what came out, should have been the same part just in better condition.

I will be pulling the trans again to put in a proper clutch from someplace that actually has one in stock. I'll try to get the engine to run better with some tuning, though this cam is in between the turbo cam I just put in the other motor and the stock eta cam. If everything with the motor were good to go it would just need some tuning on the fuel map but I fear it may have some valve sealing issues indicated by the poor idle vacuum. If the bottom end seems good and it's not using oil perhaps I'll pull the head and swap it out with the other one with the turbo cam.

I never used to have these sorts of problems. I used to build motors from a bare block and leave nothing to chance. Something to be said for that. This shit is wearing me out.

Re: Turbo ETA build

The original block:

Cylinder number 4, the worst of the bunch. No surprise it was burning oil.

All six showed signs of foreign object damage. Something went through this motor at some point in its 30 plus years.

The new motor is running better with some big changes in the tune. Vacuum is still not great but it doesn't seem to be using any oil so I'm thinking it might be good for now. The clutch is slipping less after getting, let's say, burnished somewhat. I'm probably still going to be back in there before long.

The oil leaks are fixed with the exception of the oil level sensor. This never leaked before and was installed with a new oring. Now it's dripping.

Cylinder number 4, the worst of the bunch. No surprise it was burning oil.

All six showed signs of foreign object damage. Something went through this motor at some point in its 30 plus years.

The new motor is running better with some big changes in the tune. Vacuum is still not great but it doesn't seem to be using any oil so I'm thinking it might be good for now. The clutch is slipping less after getting, let's say, burnished somewhat. I'm probably still going to be back in there before long.

The oil leaks are fixed with the exception of the oil level sensor. This never leaked before and was installed with a new oring. Now it's dripping.

Re: Turbo ETA build

What kind of FOD would cause that damage to the piston top? If that was the piston, how did the head look? That looks like my time I semi melted a piston due to low injector flowturbodan wrote: Aug 25, 2023 2:51 PM The original block:

Cylinder number 4, the worst of the bunch. No surprise it was burning oil.

All six showed signs of foreign object damage. Something went through this motor at some point in its 30 plus years.

The new motor is running better with some big changes in the tune. Vacuum is still not great but it doesn't seem to be using any oil so I'm thinking it might be good for now. The clutch is slipping less after getting, let's say, burnished somewhat. I'm probably still going to be back in there before long.

The oil leaks are fixed with the exception of the oil level sensor. This never leaked before and was installed with a new oring. Now it's dripping.

Re: Turbo ETA build

Head looks similar, irregularly shaped angular dents in the quench area. Not bad enough to worry about, just ugly. I'll probably use those pistons again in a fresh block.

I do wonder what could have caused it. All six have that damage. Could have been porcelain chunks from a bad set of platinum plugs. That would easily score the cylinder wall too.

I do wonder what could have caused it. All six have that damage. Could have been porcelain chunks from a bad set of platinum plugs. That would easily score the cylinder wall too.

Re: Turbo ETA build

Much progress has been made with this new motor. The biggest change was made upon revisiting the trigger angle offset in megasquirt. The trigger angle offset was set to 97 degrees from the vendor I purchased the PNP ECU from. I had been running that all along and it's been working well. I don't know if there is something that changed with this motor, it's still a super ETA bottom end just a different one. Changing the trigger angle offset to 84 degrees adds 13 degrees of timing across the board, and this engine responded very well to that. I also had to pull a bunch of timing out under boost though, can't just add 13 degrees up there and expect it to be fine. I am more confused than ever about the correct setting here, I may grab a timing light to verify where it thinks TDC is right now. In any case, it's running great. Idle vacuum dips down to 34 kpa when the engine is fully warmed up which is higher than either of the other camshaft/engine combos I've run but I think it's an acceptable value.

The amount of torque this B25 cam produces with the small turbo is remarkable. It pulls well from very low revs. It hits hard at 4k, whereas the catcams turbo cam comes on a little later and produces a more manageable impulse. With the B25, the midrange bump is very pronounced and tends to break traction more easily. I broke loose today while rolling into WOT in third gear, in full disclosure it was raining but still. That's some pretty good hit. I still don't know if I like the turbo cam better. They're both good.

One thing I did find while looking through datalogs was some spurious activation of acceleration enrichment during roll on's. It was triggering the TPS based AE three times before I made it to WOT while slowly putting my foot into it. The fix was to extend the taper time for the original accel event to prevent subsequent activations. EAE works on a much longer time scale than what I used to use for TPS based AE so I figured why not extend the TPS AE to work more like the wall wetting algorithm. So far so good. Throttle transitions are tricky and this is the best it's been in a long time.

If anybody needs a MS tune for a 2.7i this one is pretty good. Could always be better but this is a great start.

The amount of torque this B25 cam produces with the small turbo is remarkable. It pulls well from very low revs. It hits hard at 4k, whereas the catcams turbo cam comes on a little later and produces a more manageable impulse. With the B25, the midrange bump is very pronounced and tends to break traction more easily. I broke loose today while rolling into WOT in third gear, in full disclosure it was raining but still. That's some pretty good hit. I still don't know if I like the turbo cam better. They're both good.

One thing I did find while looking through datalogs was some spurious activation of acceleration enrichment during roll on's. It was triggering the TPS based AE three times before I made it to WOT while slowly putting my foot into it. The fix was to extend the taper time for the original accel event to prevent subsequent activations. EAE works on a much longer time scale than what I used to use for TPS based AE so I figured why not extend the TPS AE to work more like the wall wetting algorithm. So far so good. Throttle transitions are tricky and this is the best it's been in a long time.

If anybody needs a MS tune for a 2.7i this one is pretty good. Could always be better but this is a great start.

Re: Turbo ETA build

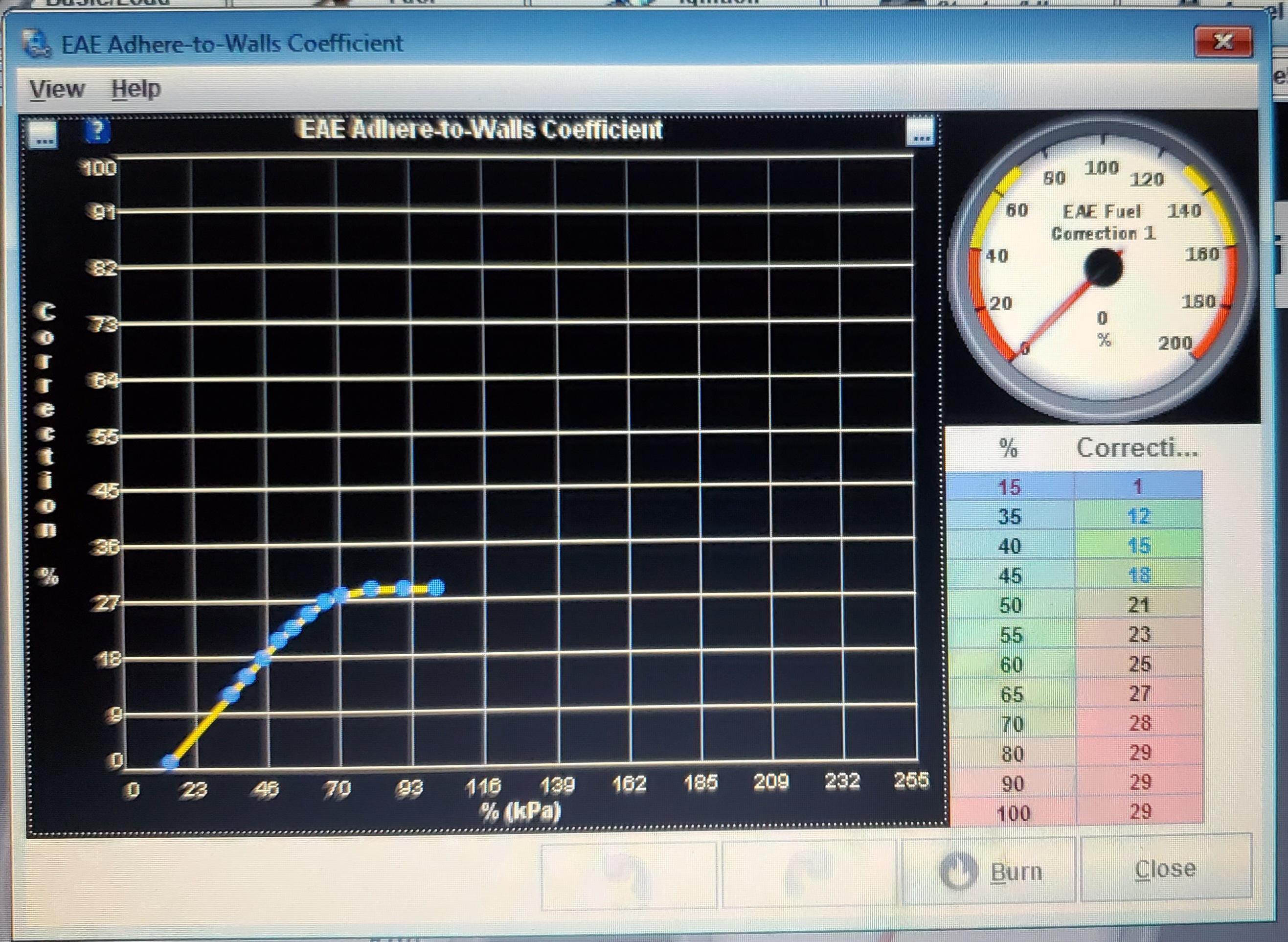

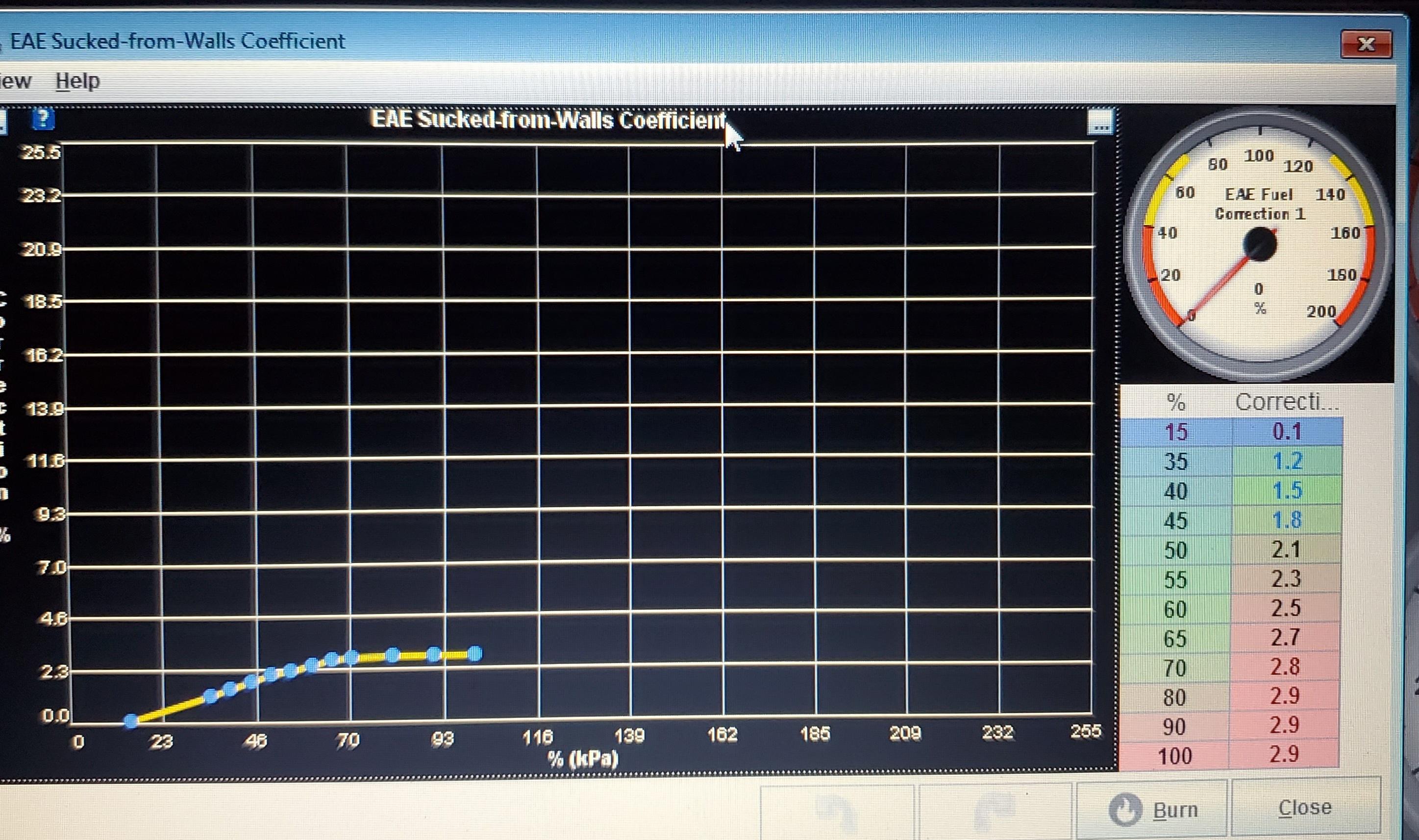

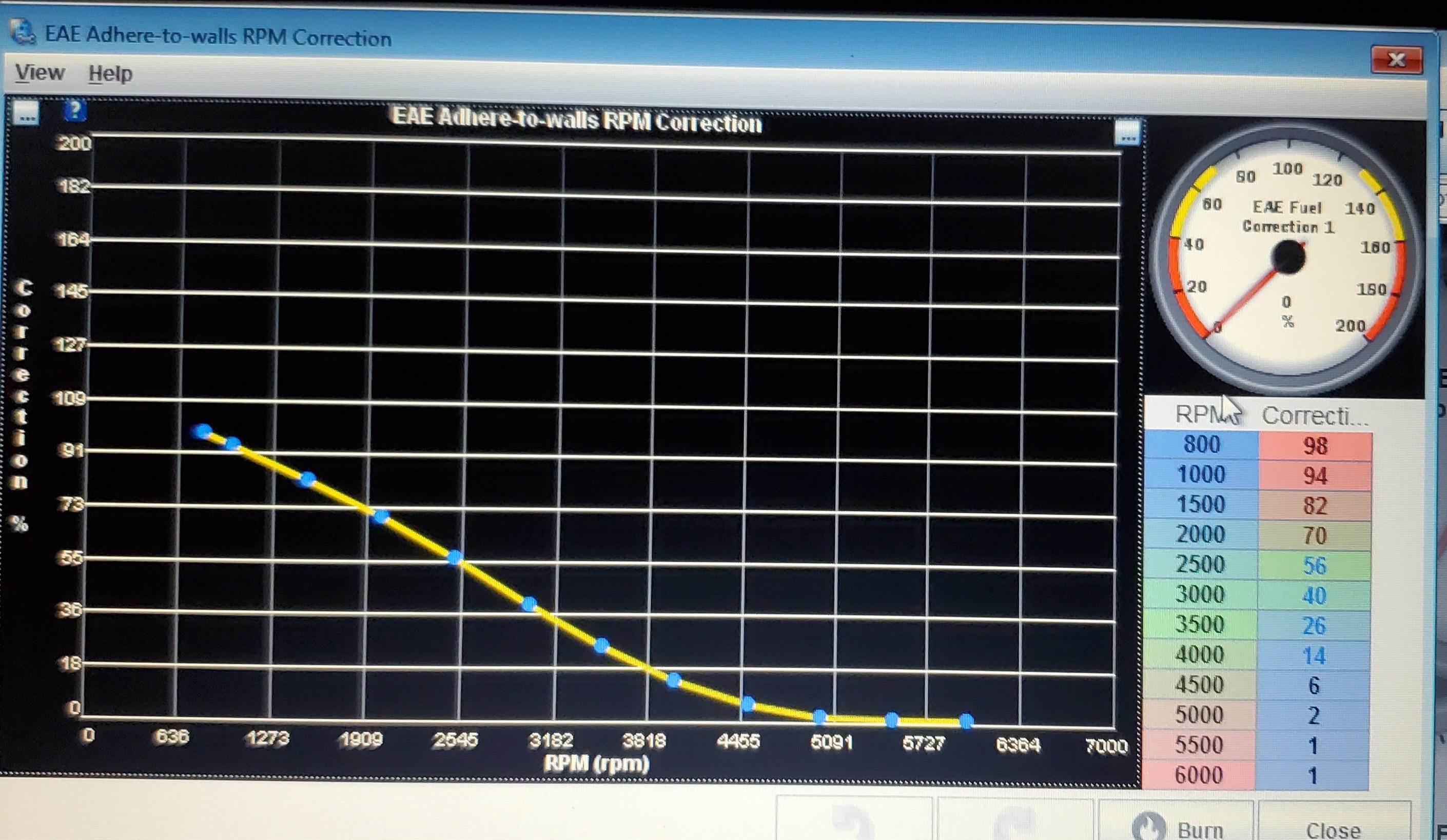

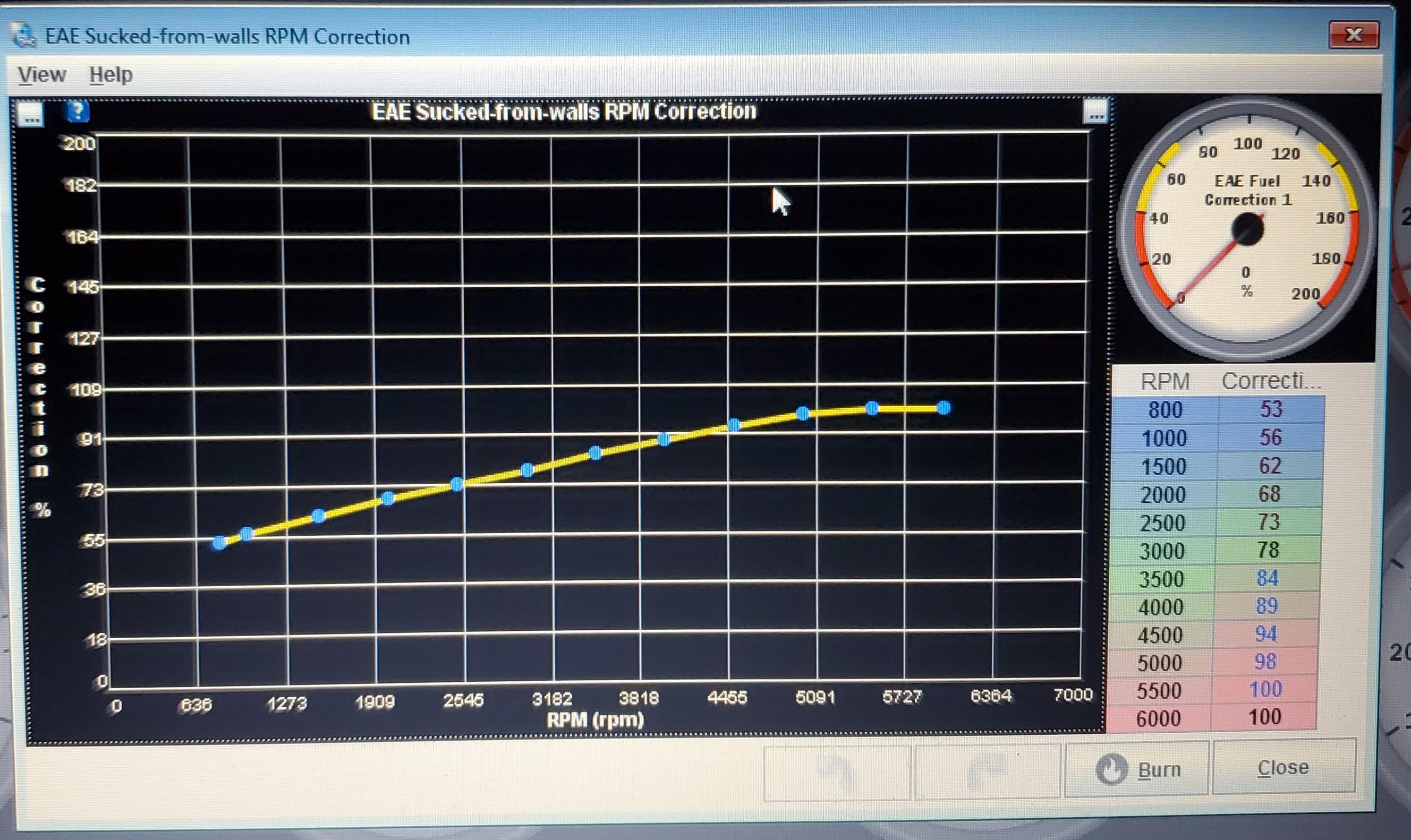

If anybody out there is fighting with EAE, these settings are working very well. I use a little bit of TPS based AE to help the rapid throttle movements but EAE does the heavy lifting with drivability. It saves gas too, pulling upwards of 30 percent out when you step off the throttle suddenly. When you lift off for a shift under boost, especially at low revs. Without EAE your AFR will go super rich. Cold drivability is much better too, it delivers enrichment for a much longer duration and in a smoother manner than traditional AE

Re: Turbo ETA build

Thanks for sharing, I will have to try similar settings! Can you share your associated tps enrichment and blend settings for reference?

Re: Turbo ETA build

Yeah I'll post em up next chance I get. These will only work properly for 30 lb injectors though unless you adjust accordingly.

Re: Turbo ETA build

I have loaded these into my next tune as I am planning to get after it with B35 engine and a retune is required anyway.

Do you ever climb in elevation? I have read about 'Percent Baro" instead of "Speed Density". Have you played with this for drivability with elevation change? Some say to use this and zero out the barometric correction curve.

I found my car would always run better in boost at high elevation even though I tuned it down the mountain. But I had issues with temperature changes and consistency of my tune in cold mornings versus hot afternoons in the summer. I also found my tune would be richer in boost as I went up in elevation and kept thinking that the curve was simply too aggressive and adding more fuel. Now I am wondering if the M30 just likes richer AFR's in general.. it idles a heck of a lot better near 13:1 than any leaner.

Do you ever climb in elevation? I have read about 'Percent Baro" instead of "Speed Density". Have you played with this for drivability with elevation change? Some say to use this and zero out the barometric correction curve.

I found my car would always run better in boost at high elevation even though I tuned it down the mountain. But I had issues with temperature changes and consistency of my tune in cold mornings versus hot afternoons in the summer. I also found my tune would be richer in boost as I went up in elevation and kept thinking that the curve was simply too aggressive and adding more fuel. Now I am wondering if the M30 just likes richer AFR's in general.. it idles a heck of a lot better near 13:1 than any leaner.

Re: Turbo ETA build

I see a variation of about 700 feet on a regular basis but that's about it. Never had to tune baro correction. I do tweak the MAT air density correction, the curves that were built in seem rich when cold and lean when hot, so I have flattened them out significantly.

Re: Turbo ETA build

Next on the list is this M50 harmonic balancer conversion. I'm planning on keeping the vbelt for the power steering pump and only converting the water pump and alternator to the multi-v belt. I should be able to run this setup without a sprung tensioner if I keep the belt length short. A true serpentine belt running everything would almost certainly require the works.

I was looking for another M20B25 balancer for this other engine but apparently people got together and decided a 30 year old bonded rubber damper is a $200 part. I'll figure out the M50 conversion before I spend 200 dollars on a junkyard pulley.

Meanwhile the car is solid. Boost is kept down to 10/11 psi on account of the stock clutch. It was slipping bad under boost right after the install but once the 15 years of garage floor dust got scrubbed off its been flawless. Don't want to push it though. I'm holding the line here and trying to avoid installing the big turbo and kevlar clutch I have sitting here for the other project car.

I may do some testing with the turbo, it is directly interchangeable with the GT2560R with the exception of the compressor inlet, I will need to make a new intake pipe and find a suitably large air filter. That's why I like these T25 units, you can bolt on the spoolmeister 2560R or you can bolt on the 2971R with almost twice as much capacity on the turbine side and about 50% more on the compressor. The 2871R sits neatly in between and made very good, very usable power on my original build. They all just bolt right up with the same 5 bolt discharge and connections at the center housing. Whatever power delivery you prefer is easy to achieve.

Re: Turbo ETA build

Updated EAE settings, after much testing and minor revision from the ones I posted in October:

Adhere to walls coefficient (same as October settings):

% Correction

15 1

35 12

40 15

45 18

50 21

55 23

60 25

65 27

70 28

80 29

90 29

100 29

Sucked from walls coefficient (also unchanged):

% Correction

15 .1

35 1.2

40 1.5

45 1.8

50 2.1

55 2.3

60 2.5

65 2.7

70 2.8

80 2.9

90 2.9

100 2.9

Adhere to walls RPM correction:

RPM %

800 100

1000 95

1500 82

2000 70

2500 56

3000 40

3500 26

4000 14

4500 6

5000 2

5500 1

6000 1

Sucked from walls RPM correction:

RPM %

800 53

1000 55

1500 60

2000 64

2500 68

3000 73

3500 80

4000 88

4500 94

5000 98

5500 100

6000 100

Adhere to walls CLT correction:

CLT Correction

0 200

20 200

40 189

60 176

80 162

100 147

120 132

140 115

160 100

170 100

180 100

Sucked from walls CLT correction:

CLT Correction

0 24

20 31

40 38

60 45

80 54

100 63

120 72

130 77

140 83

160 94

170 99

180 100

TPS based AE is as follows:

MAPdot VS TPS blend %: 60% TPS/40% MAP

MAP based AE

kPa/s Added ms

50.0 1.4

125.0 1.6

300.0 2.0

600.0 2.0

Accel MAPdot threshold: 100 kPa/sec

End Pulsewidth: 0.0 ms

Accel time: .1 s

Accel taper time: .8 s

Accel TPSdot Threshold: 20.0 %/sec

Decel fuel amount: 100

Cold accel adder: .6 ms

Cold accel multiplier: 120

Accel scaling: Full accel below 800 RPM, zero accel above 6000 RPM

EAE is not too bad to tune once you understand which variables to manipulate. The constants determine the basic values that the algorithm runs on. The max enrichment is determined by the max values on the added to walls coefficient. If its 29% at 100 kPa, it'll kick in 29% when you quickly open the throttle. The RPM and CLT corrections modify that depending on where it's at on those curves. RPM scales the enrichment down as RPM increases, CLT scales the enrichment up at low temps. Sucked from walls settings affect the most important and beneficial part of this algorithm which pulls fuel when you lift off of the throttle. Since EAE is constantly computing a numerical value to estimate the amount of fuel wetting to the intake port walls, the amount that is pulled off of the walls is crucial to keep the computed value in check. If EAE thinks there is too much or too little fuel in the ports compared to what's actually in there it throws off the whole thing. The balance between added to and sucked from has the greatest effect on drivability. If this balance is out of whack it will be late on the enrichment, resulting in a lean spike and irregular throttle response.

These settings have been tested down into the 20 degree range and the cold start drivability is excellent. I have pulled back almost all of the after start enrichment as this is redundant with EAE, which performs the same task on startup. The tradition time based AE based settings are specific to 30lb/hr injectors so they will need to be adjusted if you're running something different. In my experience, 30lb injectors are a very good choice for MS to get enough fuel in during very cold starts. I don't know what Motronic does to get an M20 to light off with 14 lb injectors unless it's just holding the injectors open while cranking. MS doesn't do that and requires quite a bit more injector to get an engine to light off at 24 degrees.

Otherwise, not much else going on with this thing. I just put gas in it and drive it. Just changed the oil yesterday. I rarely open the hood anymore now that I've gotten to a point where I can trust that the head gasket is holding. I did find a nice set of e90 335i seats locally, so I snapped those up and slapped them in:

Forgive the dust and dirtyness. It gets everywhere out here, living on dirt roads. These seats are pretty great though, the posterior expects the familiar sacked out and deteriorated e28 seat, but each time I get in I'm greeted by this firm, supportive and very comfortable new upholstery. It's a surprise every time. I need to address the driver's seat controls however, apparently the seat module requires a data line signal to stay awake. it operates for about ten seconds once power is connected, plenty of time to adjust your seat, but then it goes to sleep. I think the easiest solution here is going to be supplying the seat with a switched 12v, perhaps from the rear window circuit interrupt switch. That way I can switch power on at the push of a button, adjust the seat as needed, and switch power off again until the next time I want to move the seat. It's not something you need to do very often anyway.

Adhere to walls coefficient (same as October settings):

% Correction

15 1

35 12

40 15

45 18

50 21

55 23

60 25

65 27

70 28

80 29

90 29

100 29

Sucked from walls coefficient (also unchanged):

% Correction

15 .1

35 1.2

40 1.5

45 1.8

50 2.1

55 2.3

60 2.5

65 2.7

70 2.8

80 2.9

90 2.9

100 2.9

Adhere to walls RPM correction:

RPM %

800 100

1000 95

1500 82

2000 70

2500 56

3000 40

3500 26

4000 14

4500 6

5000 2

5500 1

6000 1

Sucked from walls RPM correction:

RPM %

800 53

1000 55

1500 60

2000 64

2500 68

3000 73

3500 80

4000 88

4500 94

5000 98

5500 100

6000 100

Adhere to walls CLT correction:

CLT Correction

0 200

20 200

40 189

60 176

80 162

100 147

120 132

140 115

160 100

170 100

180 100

Sucked from walls CLT correction:

CLT Correction

0 24

20 31

40 38

60 45

80 54

100 63

120 72

130 77

140 83

160 94

170 99

180 100

TPS based AE is as follows:

MAPdot VS TPS blend %: 60% TPS/40% MAP

MAP based AE

kPa/s Added ms

50.0 1.4

125.0 1.6

300.0 2.0

600.0 2.0

Accel MAPdot threshold: 100 kPa/sec

End Pulsewidth: 0.0 ms

Accel time: .1 s

Accel taper time: .8 s

Accel TPSdot Threshold: 20.0 %/sec

Decel fuel amount: 100

Cold accel adder: .6 ms

Cold accel multiplier: 120

Accel scaling: Full accel below 800 RPM, zero accel above 6000 RPM

EAE is not too bad to tune once you understand which variables to manipulate. The constants determine the basic values that the algorithm runs on. The max enrichment is determined by the max values on the added to walls coefficient. If its 29% at 100 kPa, it'll kick in 29% when you quickly open the throttle. The RPM and CLT corrections modify that depending on where it's at on those curves. RPM scales the enrichment down as RPM increases, CLT scales the enrichment up at low temps. Sucked from walls settings affect the most important and beneficial part of this algorithm which pulls fuel when you lift off of the throttle. Since EAE is constantly computing a numerical value to estimate the amount of fuel wetting to the intake port walls, the amount that is pulled off of the walls is crucial to keep the computed value in check. If EAE thinks there is too much or too little fuel in the ports compared to what's actually in there it throws off the whole thing. The balance between added to and sucked from has the greatest effect on drivability. If this balance is out of whack it will be late on the enrichment, resulting in a lean spike and irregular throttle response.

These settings have been tested down into the 20 degree range and the cold start drivability is excellent. I have pulled back almost all of the after start enrichment as this is redundant with EAE, which performs the same task on startup. The tradition time based AE based settings are specific to 30lb/hr injectors so they will need to be adjusted if you're running something different. In my experience, 30lb injectors are a very good choice for MS to get enough fuel in during very cold starts. I don't know what Motronic does to get an M20 to light off with 14 lb injectors unless it's just holding the injectors open while cranking. MS doesn't do that and requires quite a bit more injector to get an engine to light off at 24 degrees.

Otherwise, not much else going on with this thing. I just put gas in it and drive it. Just changed the oil yesterday. I rarely open the hood anymore now that I've gotten to a point where I can trust that the head gasket is holding. I did find a nice set of e90 335i seats locally, so I snapped those up and slapped them in:

Forgive the dust and dirtyness. It gets everywhere out here, living on dirt roads. These seats are pretty great though, the posterior expects the familiar sacked out and deteriorated e28 seat, but each time I get in I'm greeted by this firm, supportive and very comfortable new upholstery. It's a surprise every time. I need to address the driver's seat controls however, apparently the seat module requires a data line signal to stay awake. it operates for about ten seconds once power is connected, plenty of time to adjust your seat, but then it goes to sleep. I think the easiest solution here is going to be supplying the seat with a switched 12v, perhaps from the rear window circuit interrupt switch. That way I can switch power on at the push of a button, adjust the seat as needed, and switch power off again until the next time I want to move the seat. It's not something you need to do very often anyway.

-

M. Holtmeier

- Posts: 3025

- Joined: Mar 11, 2007 3:06 AM

- Location: Dallas, Texas

Re: Turbo ETA build

This is great info, thanks for sharing.

Re: Turbo ETA build

Knocked off an e60 M5 this afternoon. I wonder if he was in p500 or the 400hp mode. Either way, third gear handled that thing with ease. He just went ahead and jumped, I gave chase and walked past pretty swiftly. Safe to say it was an ass whopping.

I had to do the math on this one, I expected more of a challenge. A brief internet search reveals a 4100 pound curb weight. I've got a roughly 1200lb advantage here alone. Horsepower wise, the 507 hp of that S85 translates to about 431 at the wheels at sea-level. Up here it's down another 20 percent, so we can knock that down to 345 rear wheel. I should be in the neighborhood of 240-250 rear wheel at this boost level, but if we account for the weight difference we should be a very close match up. A 4100lb car with 345 rear wheel is right on par with a 2900lb car with 245.

If this guy was in the lower power mode, an e28 with 190 rear wheel should keep up with it. Considering the results, it seems very likely that this guy thought that would be enough. Despite the jump and me starting relatively slow for 3rd, the e60 was several carlengths behind when I shut it down.

High altitude is a real bitch with NA motors. My previous experiences, such as the C6 Z06 in the original turbo car, bear this out time and time again.

I had to do the math on this one, I expected more of a challenge. A brief internet search reveals a 4100 pound curb weight. I've got a roughly 1200lb advantage here alone. Horsepower wise, the 507 hp of that S85 translates to about 431 at the wheels at sea-level. Up here it's down another 20 percent, so we can knock that down to 345 rear wheel. I should be in the neighborhood of 240-250 rear wheel at this boost level, but if we account for the weight difference we should be a very close match up. A 4100lb car with 345 rear wheel is right on par with a 2900lb car with 245.

If this guy was in the lower power mode, an e28 with 190 rear wheel should keep up with it. Considering the results, it seems very likely that this guy thought that would be enough. Despite the jump and me starting relatively slow for 3rd, the e60 was several carlengths behind when I shut it down.

High altitude is a real bitch with NA motors. My previous experiences, such as the C6 Z06 in the original turbo car, bear this out time and time again.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

Sounds like the car is running VERY well!

Re: Turbo ETA build

This is why I am building B35 for altitude. I am at a similar elevation but it really makes a difference as you go up to 10,000+ ft!turbodan wrote: Feb 27, 2024 11:11 PM High altitude is a real bitch with NA motors. My previous experiences, such as the C6 Z06 in the original turbo car, bear this out time and time again.

Mainly B35 turbo over B34 turbo for better throttle response and reduced boost lag with the higher compression. I'll likely run a similar overall power level but lower boost setting as well just for reliability.

I have added your AAE settings to my tune but haven't tried them yet.I am going to see about upping my req_fuel setting to try to get my fuel table closer to 200 for maybe slightly better precision than in the 8's. I only have MS2 where in MS3 you can tune the fuel table to .1 digits, I am stuck with integer number and I think this is a bit of a sacrifice in fueling precision.

Re: Turbo ETA build

I guess I can imagine situations where decimal precision would be handy on the fuel table. I stick to whole numbers on the ignition map too, where I actually do have the ability to tune to the tenths.

I have slightly updated my EAE settings, I'll have to post those up. I turned the sucked from walls RPM curve down a bit and it works a little better in the 2k-3k range. I'm still not entirely happy with TPS based AE, could be a little snappier dipping into the throttle at idle but it drives perfectly so this is a low priority.

I have slightly updated my EAE settings, I'll have to post those up. I turned the sucked from walls RPM curve down a bit and it works a little better in the 2k-3k range. I'm still not entirely happy with TPS based AE, could be a little snappier dipping into the throttle at idle but it drives perfectly so this is a low priority.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

Got dyno?