question for those running a flipped TB intake manifold

question for those running a flipped TB intake manifold

I think this applies to the B34 and B35.

I've got a reverse TB intake that i'm going to be running on my b35. Does anyone have a schematic or pictures of throttle cable routing?

Maybe its just because i havent actually installed it yet but i'm having a hard time seeing the best way to route the cable without sneaking it between the intake runners somehow.

I've got a reverse TB intake that i'm going to be running on my b35. Does anyone have a schematic or pictures of throttle cable routing?

Maybe its just because i havent actually installed it yet but i'm having a hard time seeing the best way to route the cable without sneaking it between the intake runners somehow.

haha. Yeh it was late... It's not welded yet. Only intake manifold with the tb on the other side that I recall was goodntights n his is just welded to the intake(if I remember correctly). Yours has the bend. I'm just trying to decide which would be better/easier to route intake tubing too before I actually get stuff welded.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

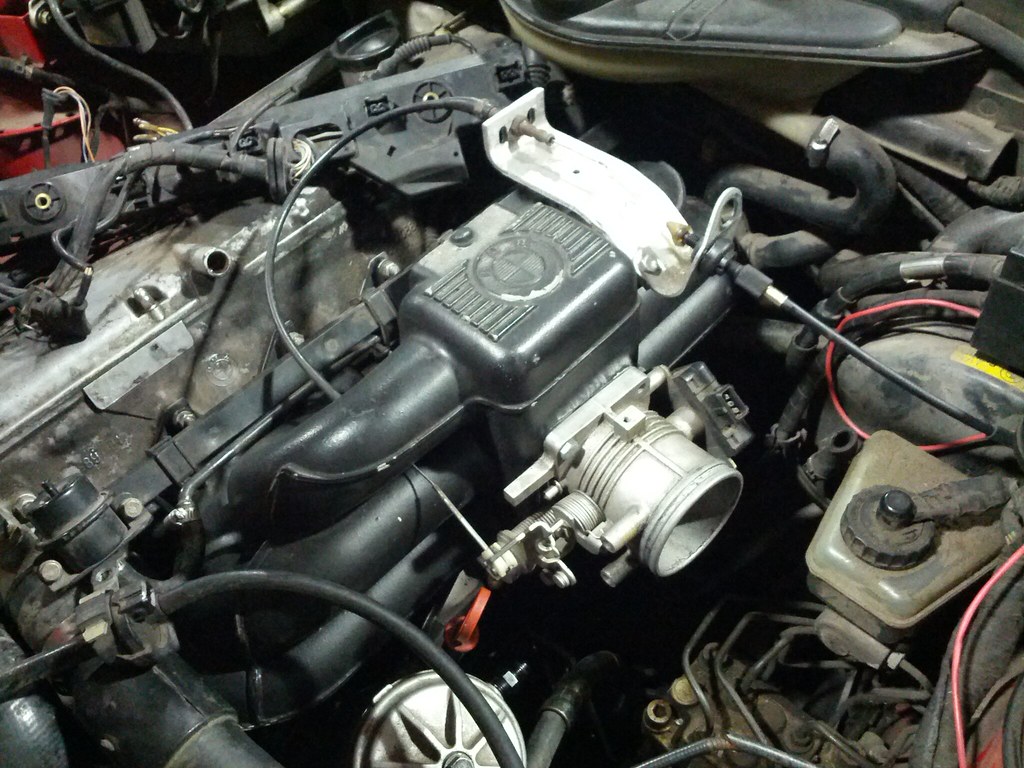

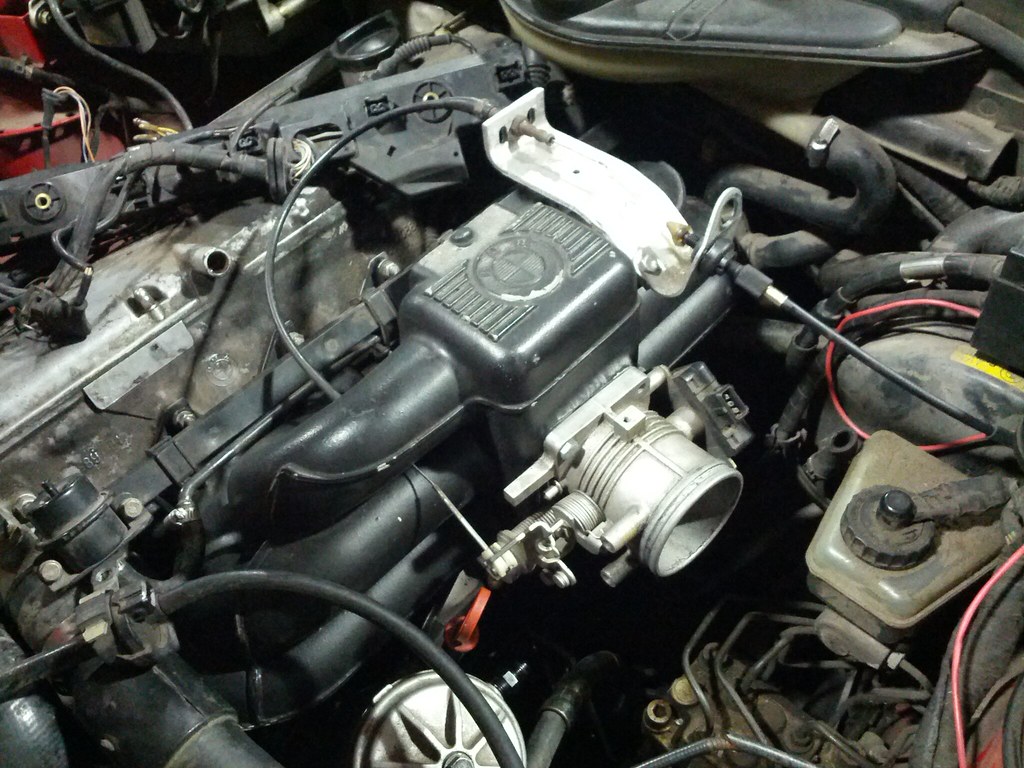

Finally got my manifold welded up to put the throttle body on the opposite side.

Uploaded with ImageShack.us

Uploaded with ImageShack.us

Uploaded with ImageShack.us

I think the costs were about $16 for the 3" 90degree cast aluminum bend off ebay. $18 for a 12X12 inch 1/4 thick sheet of 6061 aluminum off ebay. And $50 to get it all welded together. If it doesn't rain this weekend ill hopefully get it put on. Still need to drill a hole for my brake booster line fitting and try to find a squirrley hose to attach to the original icv port or drill a new one, which i'd rather not do.

Uploaded with ImageShack.us

Uploaded with ImageShack.us

Uploaded with ImageShack.us

I think the costs were about $16 for the 3" 90degree cast aluminum bend off ebay. $18 for a 12X12 inch 1/4 thick sheet of 6061 aluminum off ebay. And $50 to get it all welded together. If it doesn't rain this weekend ill hopefully get it put on. Still need to drill a hole for my brake booster line fitting and try to find a squirrley hose to attach to the original icv port or drill a new one, which i'd rather not do.

any chance you could post links to the auctions or sellers you bought from? always nice to go with an ebay seller that someone has had good luck with.jim325 wrote:

I think the costs were about $16 for the 3" 90degree cast aluminum bend off ebay. $18 for a 12X12 inch 1/4 thick sheet of 6061 aluminum off ebay. And $50 to get it all welded together. If it doesn't rain this weekend ill hopefully get it put on. Still need to drill a hole for my brake booster line fitting and try to find a squirrley hose to attach to the original icv port or drill a new one, which i'd rather not do.

much appreciated. i'm doing something similar, though i'll likely make it a bolt on rather than weld on.jim325 wrote:just-intercoolers for the 3" aluminum elbow. This one took a little longer than expected to ship.

exact_metals for the aluminum plate- was actually about $17 plus $11 shipping. Shipped really fast.

-

mooseheadm5

- Beamter

- Posts: 23035

- Joined: Apr 08, 2009 10:30 PM

- Location: Charlottesville, VA

- Contact:

bump.

same crowd, different question.

i've got some stuff hooked up:

Throttle body mounted, cables all run.

Here's where the two cables meet.

anyone have any ideas on connecting the two cables together? i used a 18gauge butt splice just to measure 0-100% throttle but after about 5 throttle punches it comes loose (no surprise there). I know you can get some connection thingies for 10spd bikes that might work. any other options?

same crowd, different question.

i've got some stuff hooked up:

Throttle body mounted, cables all run.

Here's where the two cables meet.

anyone have any ideas on connecting the two cables together? i used a 18gauge butt splice just to measure 0-100% throttle but after about 5 throttle punches it comes loose (no surprise there). I know you can get some connection thingies for 10spd bikes that might work. any other options?

Thats going to be a chronic point of failure. You may have acceptable results with lead solder if you wind the two cables together and overlap them a fair amount before applying solder. You will need to spread the load out as much as possible for that to work.

Ideally you would find a way to route the cable that doesn't involve attempting to splice additional cable in. Thats never a good idea.

Ideally you would find a way to route the cable that doesn't involve attempting to splice additional cable in. Thats never a good idea.

Crimp them together.

I think a bike shop could do it for you.

Like this.

http://www.pet-dog-cat-supply-store.com ... 185825.jpg

I think a bike shop could do it for you.

Like this.

http://www.pet-dog-cat-supply-store.com ... 185825.jpg

i'll take all that into account.

i'm looking at alternate ways of routing the cable still but so far haven't found anything acceptable.

the crimp method should be good from what research i've done. if its strong enough for a brake cable, it should be fine for a throttle cable. i just need a bit longer cable for it to work properly.

i'm looking at alternate ways of routing the cable still but so far haven't found anything acceptable.

the crimp method should be good from what research i've done. if its strong enough for a brake cable, it should be fine for a throttle cable. i just need a bit longer cable for it to work properly.

-

thespeedfactory

- Posts: 561

- Joined: Mar 01, 2012 7:26 PM

- Location: Eden, Utah

Ideal situation is to run new cable and crimp/solder either the hook on the pedal or the t bar at the throttlebody. I used a mechanical connector when it was on mine for 4 years and no issues. Just make sure that the crimp is far enough away from the far fitting to not interfere with WOT. Looking forward to seeing your build complete.

I have to take 2 years off of my build for my time in Korea, until 2014 I will have to live vicariously through the builds of others.

Found a pic of the topside plumbing from my 3rd build, FMIC and a T61.

I have to take 2 years off of my build for my time in Korea, until 2014 I will have to live vicariously through the builds of others.

Found a pic of the topside plumbing from my 3rd build, FMIC and a T61.