Rising rate fuel pressure

Rising rate fuel pressure

Ive been trying to figure out my rising rate fuel pressure today, trying to see if upping the pressure will help with a stumble I have at 4500rpm 3rd gear at 16psi, I was wondering what everyone else has there rising rate fuel pressure regs set to. At idle im at 36psi. This is the calcutation for the pressure needed. found this on

http://www.cartech.net/fmu2020instruc.htm

Pressure calculation: the fuel pressure required increases with the square of the boost pressure ratio:

Example: 6 psi boost is a pressure ratio of 1.41. With stock fuel pressure of 36 at zero boost, then:

Needed fuel pressure = (PR2 x Base Fuel Pressure) + Boost = (1.412 x 36) + 6 = 77.5 psi

If anyone can help me figure this calcutation out. brain isnt working today. My car is running 16.5psi boost pressure. I would assume that idle pressure should be at stock level right????

Also the car is a m106 on ms1. stock fuel pressure is 3bar or 43.51psi

http://www.cartech.net/fmu2020instruc.htm

Pressure calculation: the fuel pressure required increases with the square of the boost pressure ratio:

Example: 6 psi boost is a pressure ratio of 1.41. With stock fuel pressure of 36 at zero boost, then:

Needed fuel pressure = (PR2 x Base Fuel Pressure) + Boost = (1.412 x 36) + 6 = 77.5 psi

If anyone can help me figure this calcutation out. brain isnt working today. My car is running 16.5psi boost pressure. I would assume that idle pressure should be at stock level right????

Also the car is a m106 on ms1. stock fuel pressure is 3bar or 43.51psi

-

marc79euro645

- Posts: 513

- Joined: Dec 08, 2008 11:33 PM

Im not tuning fuel pressure with the MS. just running a adaptor to eliminate the stock fpr and a remote mounted rrfpr. works great.

Im using a msd blaster 2 coil. If i run stock coil it runs like crap and happens all the time. Was using to MS board ignition module, swapped that out of a bosch external ignition module.

I changed my plugs out again with BPR7ES recently. Still no change. I tried running tunerstudio with the auto tune to see if it would catch it. no luck. Its wierd not even the afr's really change when it happens. almost like a rev limiter hitting for a sec. I max out the boost limiter settings to see if that was doing it. nothing.

Maybe a new set of spark plug wires is in the mix, still running the old stock bosch ones that came with my m106 motor. cap and rotor I know are new-ish, 2yrs old tops.

Im using a msd blaster 2 coil. If i run stock coil it runs like crap and happens all the time. Was using to MS board ignition module, swapped that out of a bosch external ignition module.

I changed my plugs out again with BPR7ES recently. Still no change. I tried running tunerstudio with the auto tune to see if it would catch it. no luck. Its wierd not even the afr's really change when it happens. almost like a rev limiter hitting for a sec. I max out the boost limiter settings to see if that was doing it. nothing.

Maybe a new set of spark plug wires is in the mix, still running the old stock bosch ones that came with my m106 motor. cap and rotor I know are new-ish, 2yrs old tops.

-

mooseheadm5

- Beamter

- Posts: 23035

- Joined: Apr 08, 2009 10:30 PM

- Location: Charlottesville, VA

- Contact:

-

Mr Project

- Posts: 158

- Joined: Jul 12, 2006 8:04 PM

- Location: Lincoln, NE

The rising rate I have you dont have to run the stock fpr. I had them both on there for a year and had terrible mpg, and it dumped fuel like crazy. Was told by my buddy that builds and tunes MS that I dont have the stock fpr with this rising rate. I still not 100% that its fuel thats causing this problem in higher RPM. I ordered a set of 8mm spark wires from TCD, they will be here on friday the 17th, I have to install them and see if that helps.

Which rising rate regulator do you have?

Your buddy should have told you that you don't need the RRFPR at all when tuning with MS. You can add all the fuel you need in the VE table. I would only consider an RRFPR with MS if you wanted to run smallish injectors to have better fueling control under low MAP conditions while still being able to support high power levels. Its an alternative to staged injection IMO, but none of that is necessary unless you're running well over 500rwhp.

Your buddy should have told you that you don't need the RRFPR at all when tuning with MS. You can add all the fuel you need in the VE table. I would only consider an RRFPR with MS if you wanted to run smallish injectors to have better fueling control under low MAP conditions while still being able to support high power levels. Its an alternative to staged injection IMO, but none of that is necessary unless you're running well over 500rwhp.

Found a m30 3bar in my garage, installed it and got on the freeway with the autotune hooked up. problem at 4500rpm seems to be gone, still got a couple of things going on which I believe is from the spark wires. thanks for the help.

Does anyone else running a m106 on ms1 that gets a dropping idle problem and starts dropping from 1000 to 500 RPM until you snap the throttle. afrs read 18 to 20 when its doing it. Im running the stock m106 idle control system that under the metal hard pipe, all the lines and idle control are brand new.

Does anyone else running a m106 on ms1 that gets a dropping idle problem and starts dropping from 1000 to 500 RPM until you snap the throttle. afrs read 18 to 20 when its doing it. Im running the stock m106 idle control system that under the metal hard pipe, all the lines and idle control are brand new.

All you can do to avoid that is increase the fuel cut threshold or add fuel in the VE bins that the engine passes through as it returns to idle. Your code variant may have some kind of wall wetting compensation, I think MS1 had X-Tau correction whereas MS2 has EAE. Its great for condition like yours which you can't usually tune out in the VE table. It compensates for the lean condition that results from the fuel being pulled from the port walls as the revs drop back to idle.

Either you can implement that or just tune the low MAP low RPM bins rich to mask the issue.

Either you can implement that or just tune the low MAP low RPM bins rich to mask the issue.

So basically as the RPM pass though that lower area on the ve table just add fuel untill its gone?

for some reason it seems to happen more after I start the car, say if I went into a store after the engine is warm up, start the car and the afr's read 18ish and the RPM start hunting. reving up doesnt help but if I start it up and instantly start driving the problem is gone. I removed after start enrichment to see if that helps. nothing.

thanks for the help

for some reason it seems to happen more after I start the car, say if I went into a store after the engine is warm up, start the car and the afr's read 18ish and the RPM start hunting. reving up doesnt help but if I start it up and instantly start driving the problem is gone. I removed after start enrichment to see if that helps. nothing.

thanks for the help

Afterstart enrichment actually sounds like what you need. Your AFR is reading lean because the port walls are dry. It takes a little afterstart enrichment to compensate for the fuel being added to the port walls until they reach a normal condition.

What are your IAT's when you jump back into the car but before you start it? Another possibility is that the motor is heatsoaking in the short period of time that it sits and giving the IAT sensor a false reading. If you have your sensor mounted in the intake manifold or throttle body this can be an issue.

What are your IAT's when you jump back into the car but before you start it? Another possibility is that the motor is heatsoaking in the short period of time that it sits and giving the IAT sensor a false reading. If you have your sensor mounted in the intake manifold or throttle body this can be an issue.

its mounted on the hard pipe that attaches to the throttle body on the m106 motor.

where does everyone else put it. I was told to put as close the the throttle body as I could while still having it before the intake manifold. When I redo my intercooler piping I was planning on putting it around the dipstick area not so much above the engine.

where does everyone else put it. I was told to put as close the the throttle body as I could while still having it before the intake manifold. When I redo my intercooler piping I was planning on putting it around the dipstick area not so much above the engine.

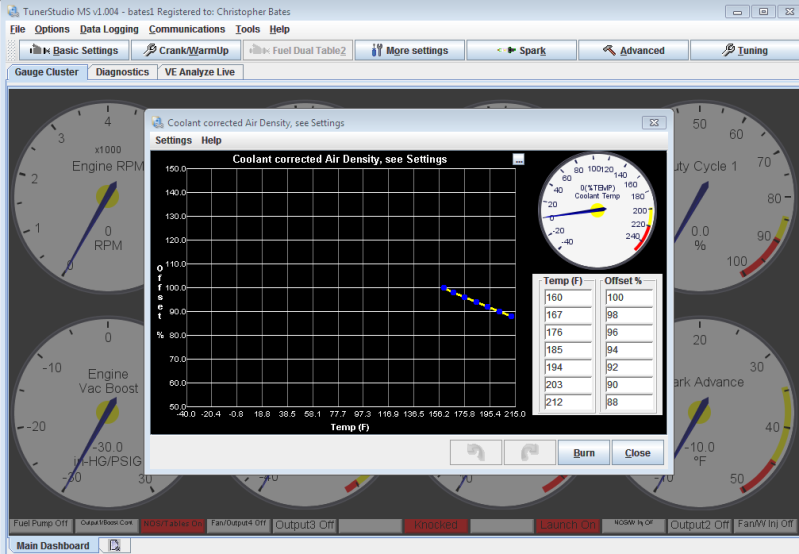

Coolant Related Air Density

This is for experienced users to alter their air density correction with coolant temperature rather than with air temperature. Some people have found that their engines lean out due to the air temp sensor becoming saturated by the engine's heat, this gives the ECU the impression the incoming air is really hot when in fact it is simply the sensor that’s been heated up by the mass of the engine.

To help TUNE this we have added Coolant Correction percentage.

With this function enabled the correction percentage is interpolated from the table, depending on the coolant temperature. So Air Density would now be :

Air Density = (MAT Related Air Density) * Coolant related correction %

E.G. Air Density = 120 * 110 % = 132

This correction can then be reduced by the engines RPM. The Reduction Start value is where the coolant correction is started to be removed, and the correction End position is where there will no longer be any coolant correction. The coolant correction is interpolated between these 2 points. At engine speeds lower then the start point the correction will be as the Coolant Correction Table. Between the Start and End values the Coolant Correction is reduced at a linear rate. At the End value the Coolant Correction rate is removed totally.

The idea is that as rpm increases as does air flow, so the MAT sensor will be a more realistic measurement of density.

So if start is 3000rpm and end is 6000, and correction is 150%, then at 3000rpm correction will be 150%, at 4500rpm correction will be 125% and at 6000rpm correction will be 100% (i.e. no correction).

We have allowed the temperatures to be user defined, suggested temps would be :

Temp 1 = -40 F

Temp 2 = -20 F

Temp 3 = 0 F

Temp 4 = 20 F

Temp 5 = 50 F

Temp 6 = 80 F

Temp 7 = 120 F

To ensure this selection is OFF go into "Coolant Related Air Density" then select "Settings" and ensure the selection is "NORMAL CORRECTION"

copied from the ms1 manual.

This is for experienced users to alter their air density correction with coolant temperature rather than with air temperature. Some people have found that their engines lean out due to the air temp sensor becoming saturated by the engine's heat, this gives the ECU the impression the incoming air is really hot when in fact it is simply the sensor that’s been heated up by the mass of the engine.

To help TUNE this we have added Coolant Correction percentage.

With this function enabled the correction percentage is interpolated from the table, depending on the coolant temperature. So Air Density would now be :

Air Density = (MAT Related Air Density) * Coolant related correction %

E.G. Air Density = 120 * 110 % = 132

This correction can then be reduced by the engines RPM. The Reduction Start value is where the coolant correction is started to be removed, and the correction End position is where there will no longer be any coolant correction. The coolant correction is interpolated between these 2 points. At engine speeds lower then the start point the correction will be as the Coolant Correction Table. Between the Start and End values the Coolant Correction is reduced at a linear rate. At the End value the Coolant Correction rate is removed totally.

The idea is that as rpm increases as does air flow, so the MAT sensor will be a more realistic measurement of density.

So if start is 3000rpm and end is 6000, and correction is 150%, then at 3000rpm correction will be 150%, at 4500rpm correction will be 125% and at 6000rpm correction will be 100% (i.e. no correction).

We have allowed the temperatures to be user defined, suggested temps would be :

Temp 1 = -40 F

Temp 2 = -20 F

Temp 3 = 0 F

Temp 4 = 20 F

Temp 5 = 50 F

Temp 6 = 80 F

Temp 7 = 120 F

To ensure this selection is OFF go into "Coolant Related Air Density" then select "Settings" and ensure the selection is "NORMAL CORRECTION"

copied from the ms1 manual.

-

marc79euro645

- Posts: 513

- Joined: Dec 08, 2008 11:33 PM

hunting is typical if your idle area of both ve & spark are not level, watch the 3d map,then go to your tables and level out your idle plateau. If your using autotune,I recomend turning controler authority down to 1, tune manually with the q&w keys in 3d map mode, type g to have cursor follow the marker. I've seen some strange maps from autotune.

good luck

marc

good luck

marc