I've decided I needed a few upgrades to my garage/workshop...

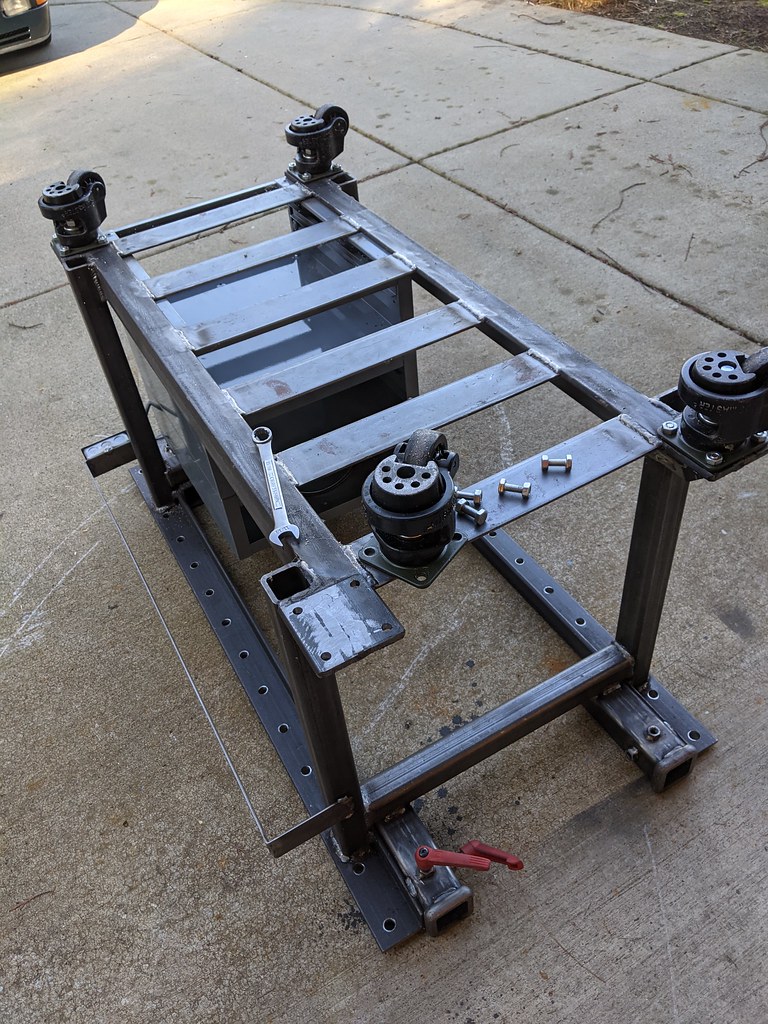

The first is the welding table. When I finished it in 2017 I had no idea what I was doing as a welder. I'm not much wiser now, but I have learned a few things. And I got some things wrong when I built it.

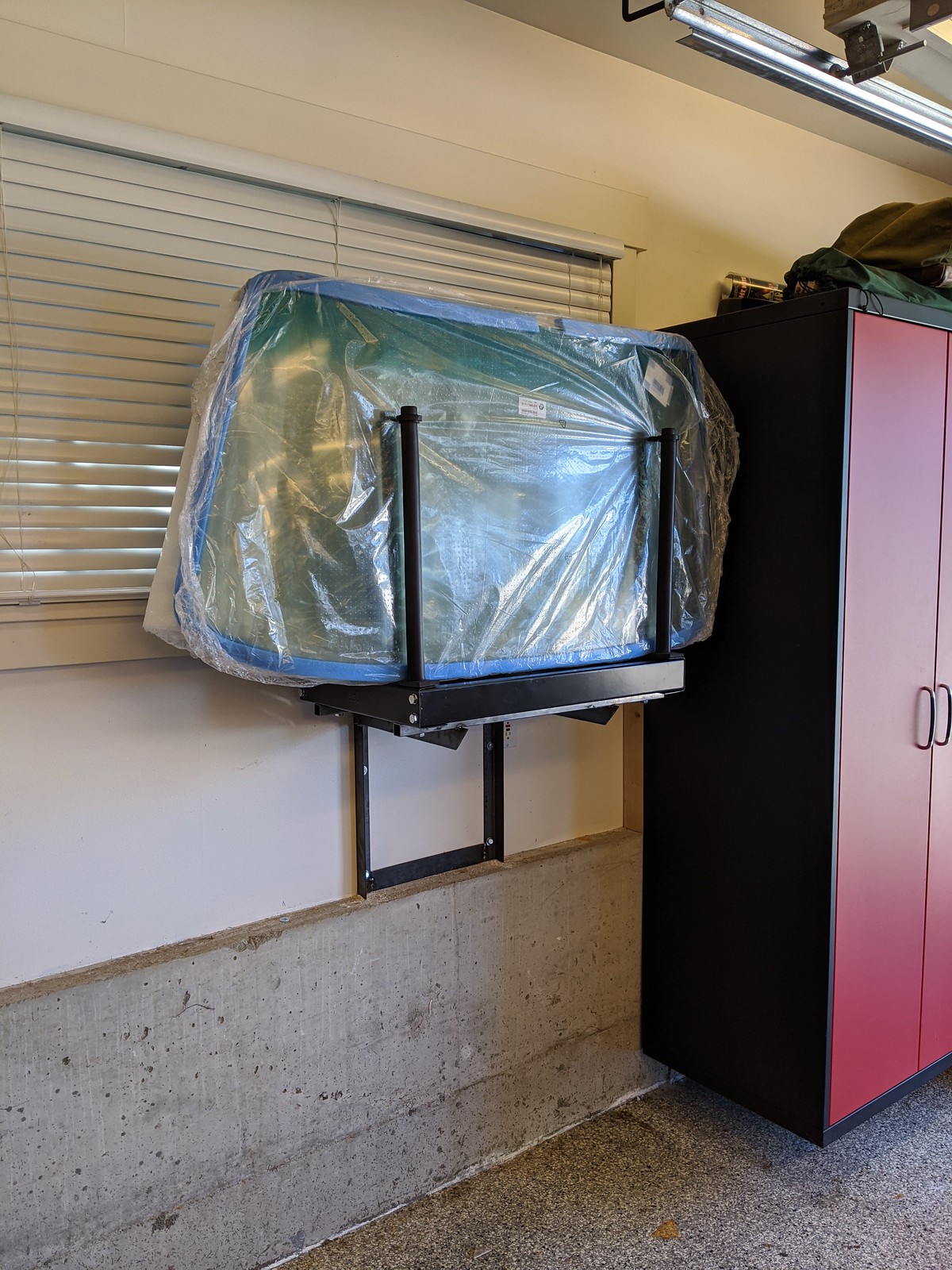

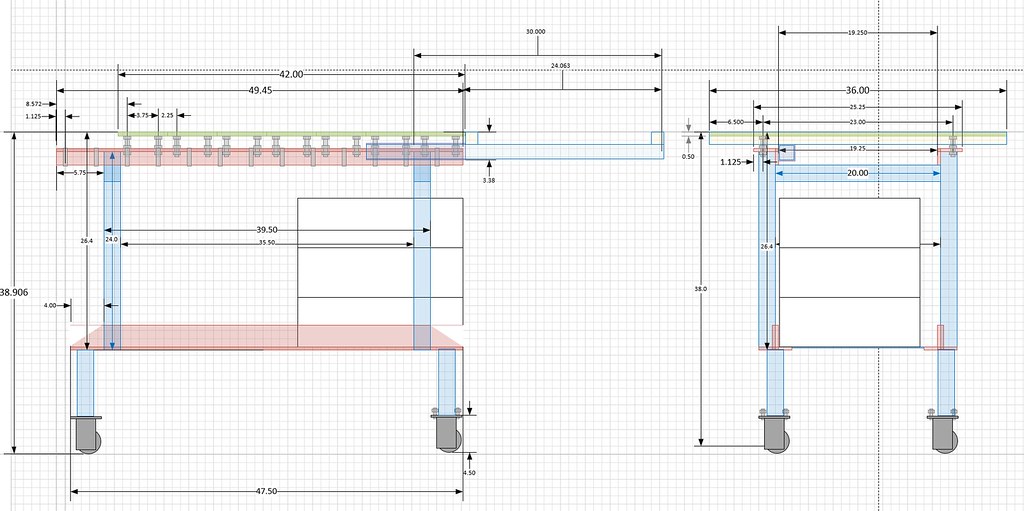

First, it's way overbuilt. It is too heavy and too long. There's not much I can do about the weight, and I'm ok with the width, but I can tweak the length.

Second, the gaps between the slats drive me nuts. I'm always dropping things between them. And, I'm jealous of the

BuildPro-style tables with the grid of 5/8" holes throughout for fixturing.

So I'm going to bring the slats together and drill a massive number of holes.

Third, it's too short. I made it desk height (~29") and my back does not appreciate that. So I'm going to make it taller by about 8-9".

I also want to paint it (red) and I'd like to have a plasma grate I can use for easier plasma cutting.

On making it a bit shorter: by bringing the slats together I will remove about 3" of length off the end with cabinets. I have deleted the hitch receivers on that end as well (details to follow). 3" may not sound like a lot, but it means I can more effectively store the beast more effectively.

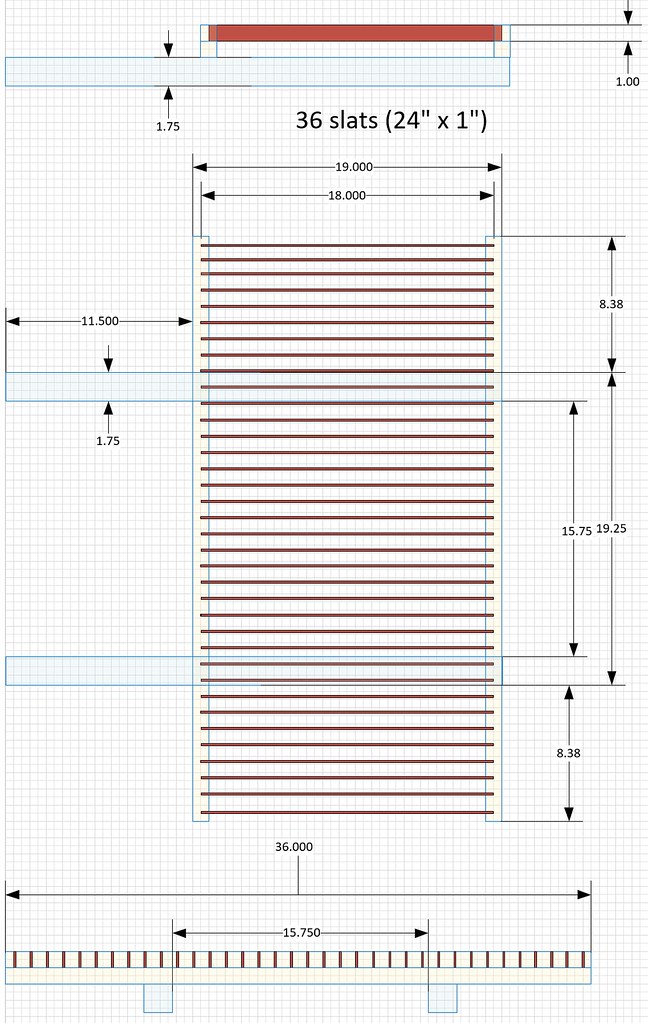

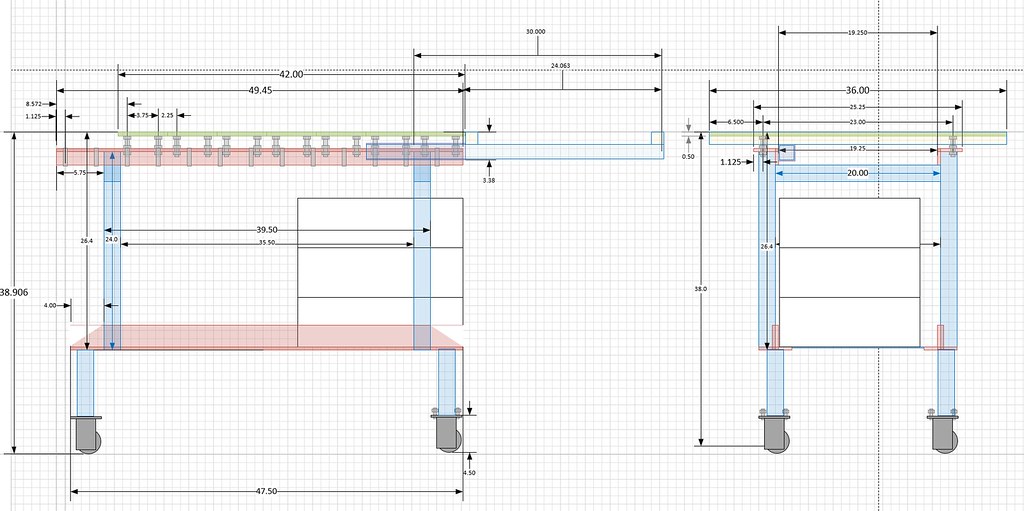

Here's the new design:

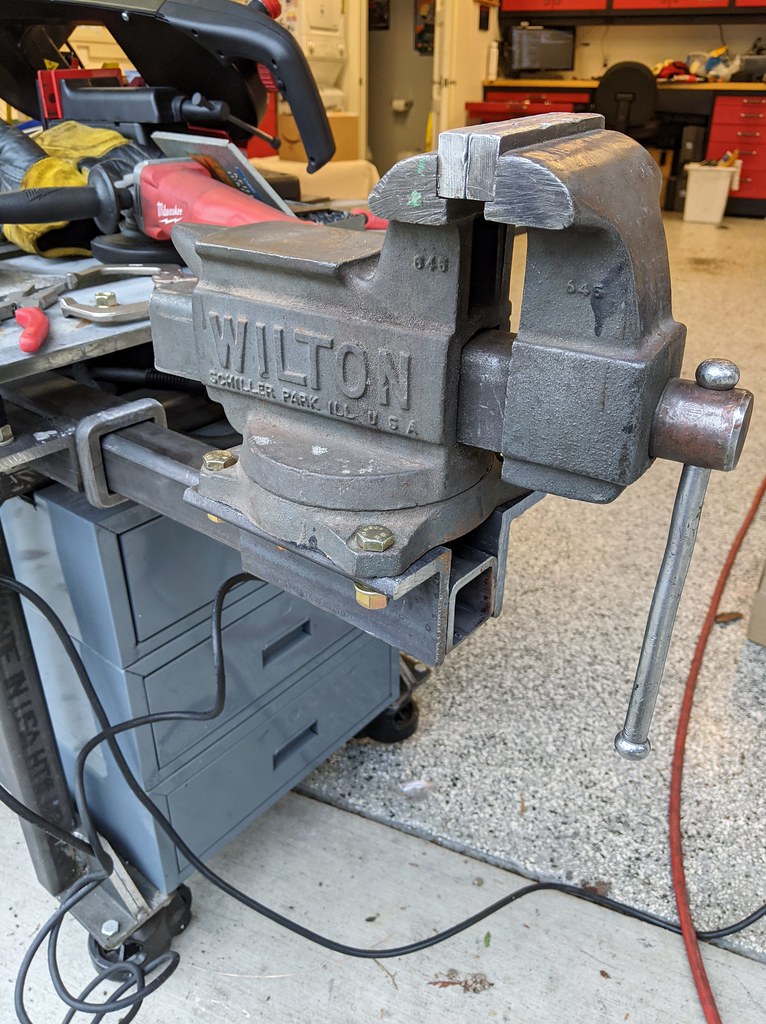

Note that I have no plan for the area of the top to the left, where the vise/grinder go. I may source another 1/2"x6"x36" plate, I may leave the space empty (makes using the vise easier), or I may put wood there. Still thinking about that.

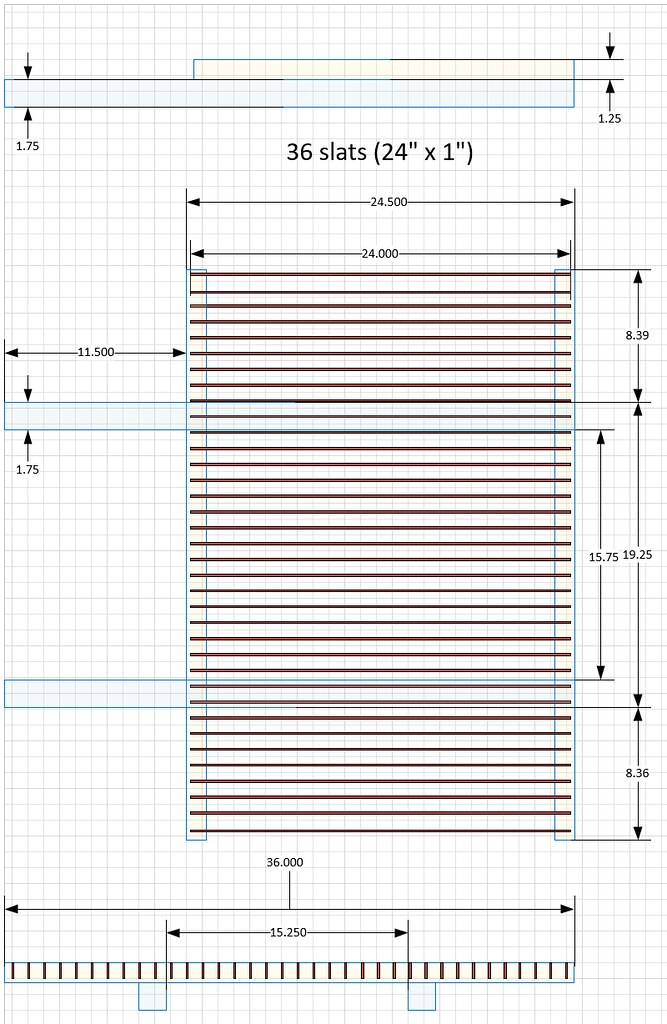

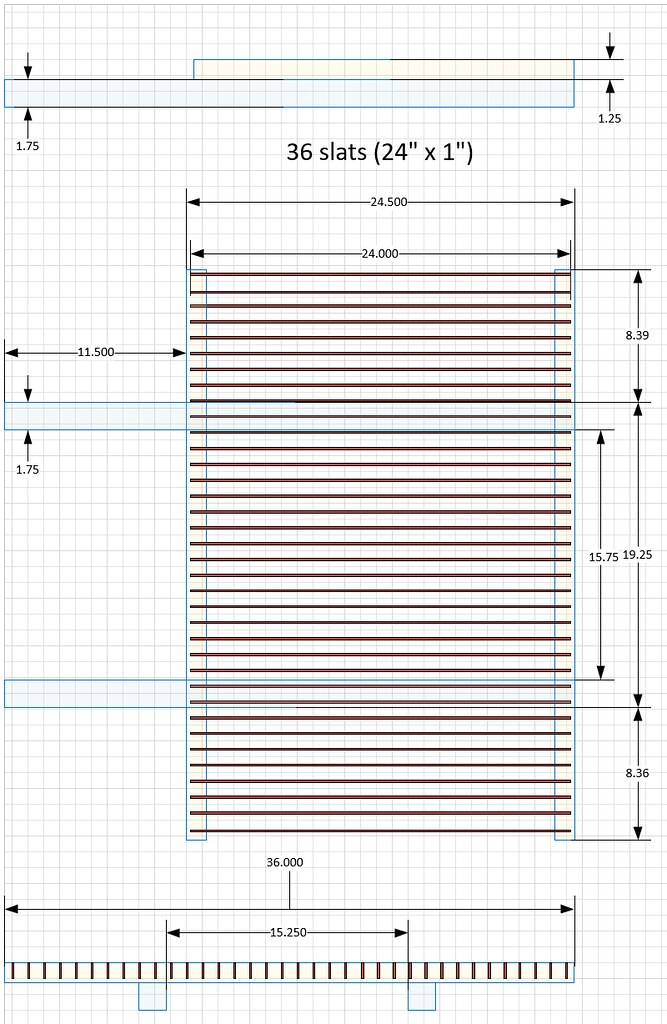

On the right side, note the plasma grate. It will slide on/off using 2" & 1 3/4" OD square "Telespar" tubing (no interior welds, designed for telescoping) and I'll be able to store it on the side opposite where I hang tools. Here's the design of the plasma grate. it will provide a 36"x18" surface for doing plasma cutting and will sit flush with that top (Ignore that it says the slats will be 24" long; they will be 18").

All the material for this is on-hand and my goal is to build the plasma tray this weekend.

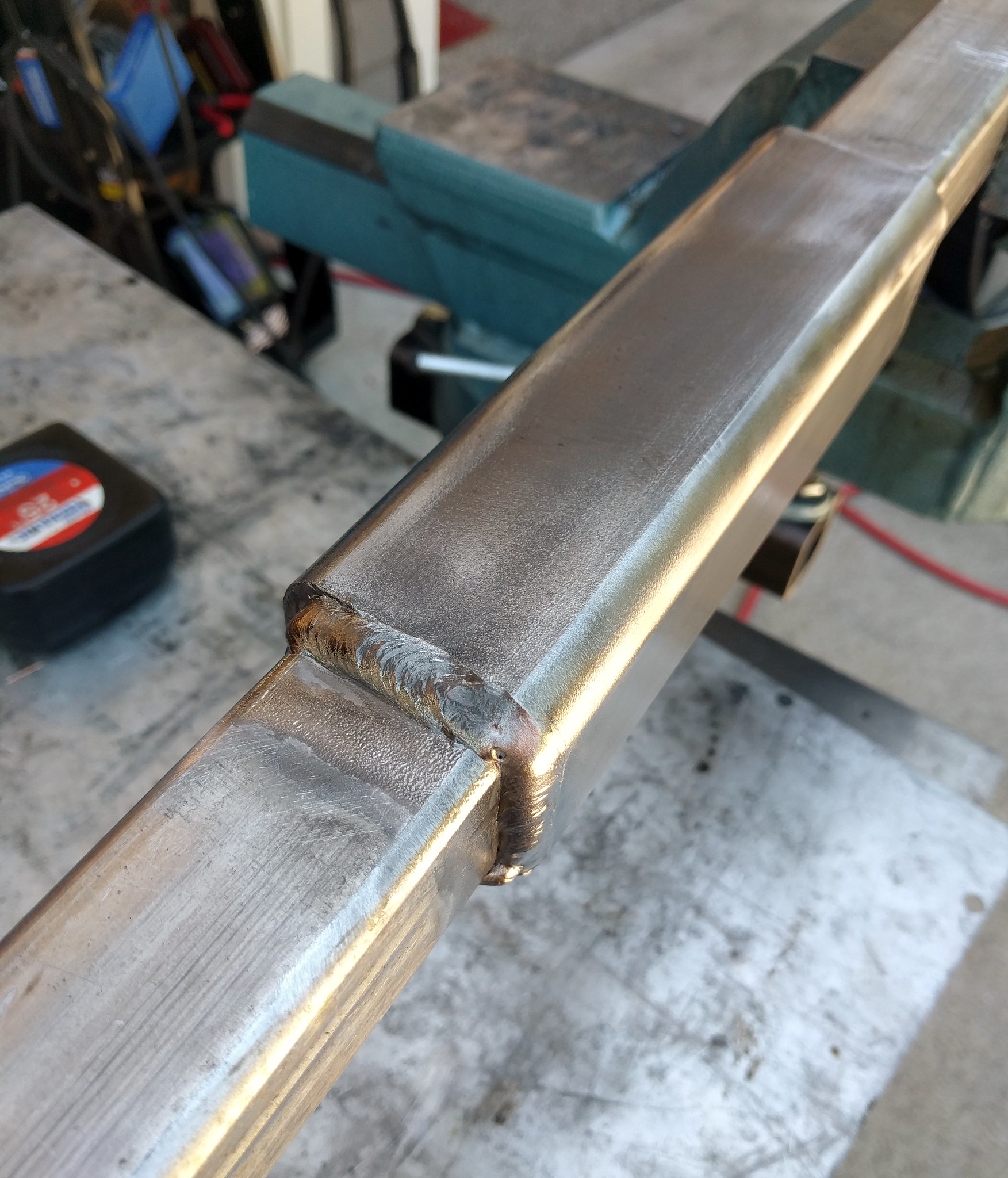

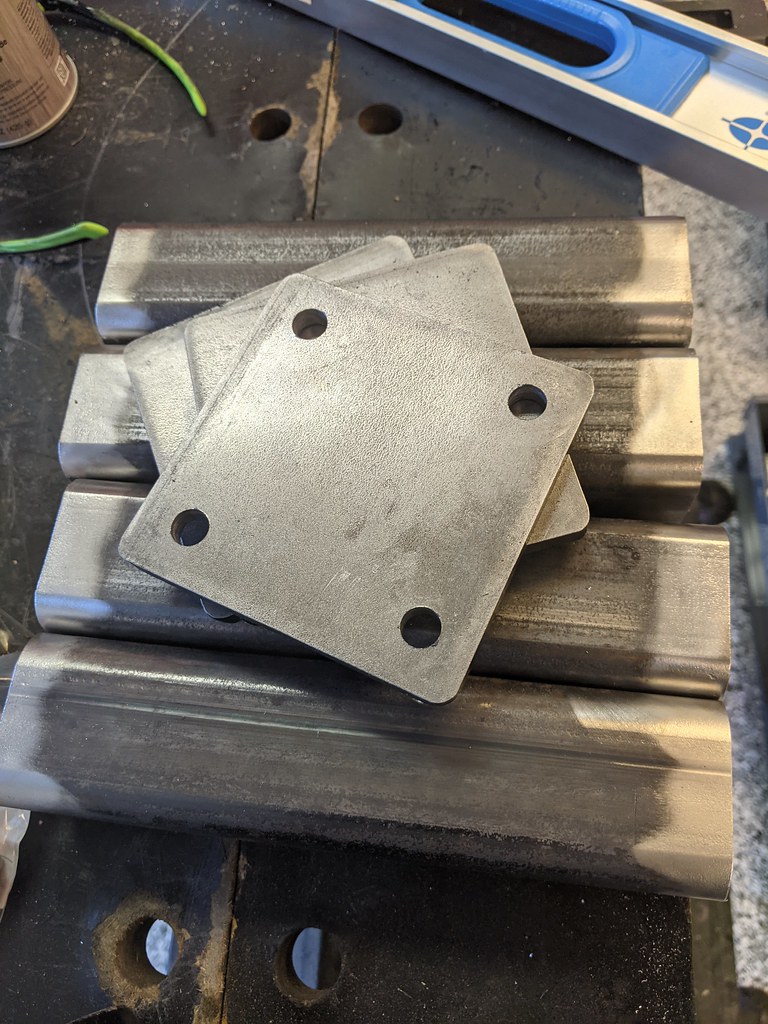

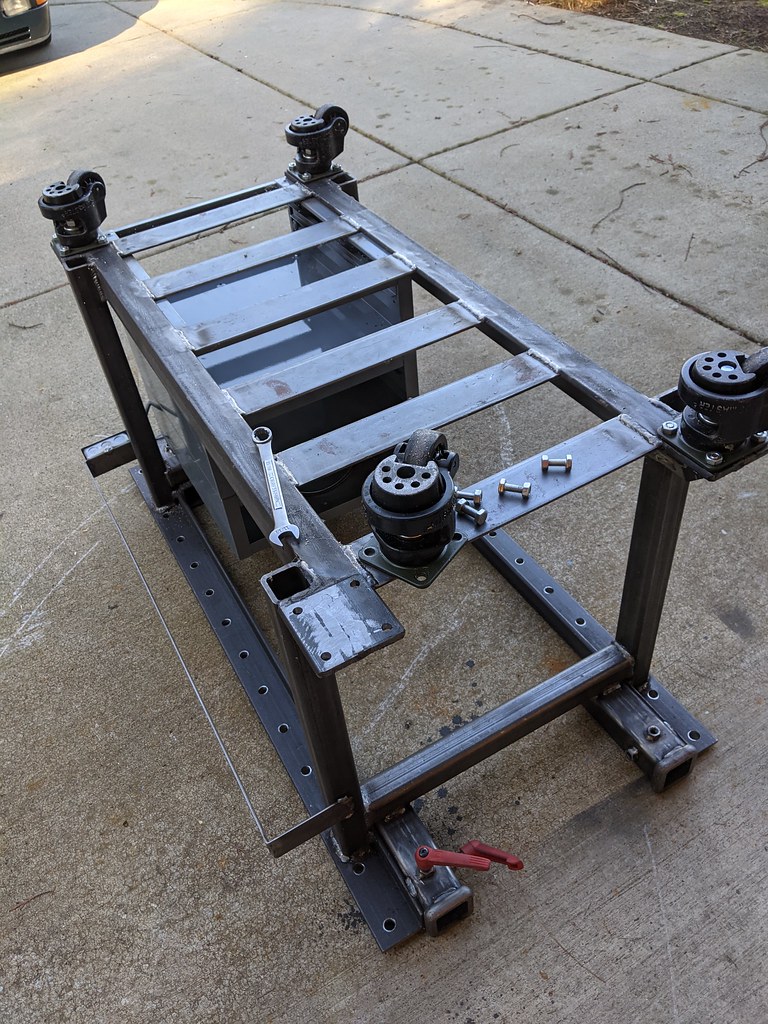

As for making it taller: I've already done it...

After:

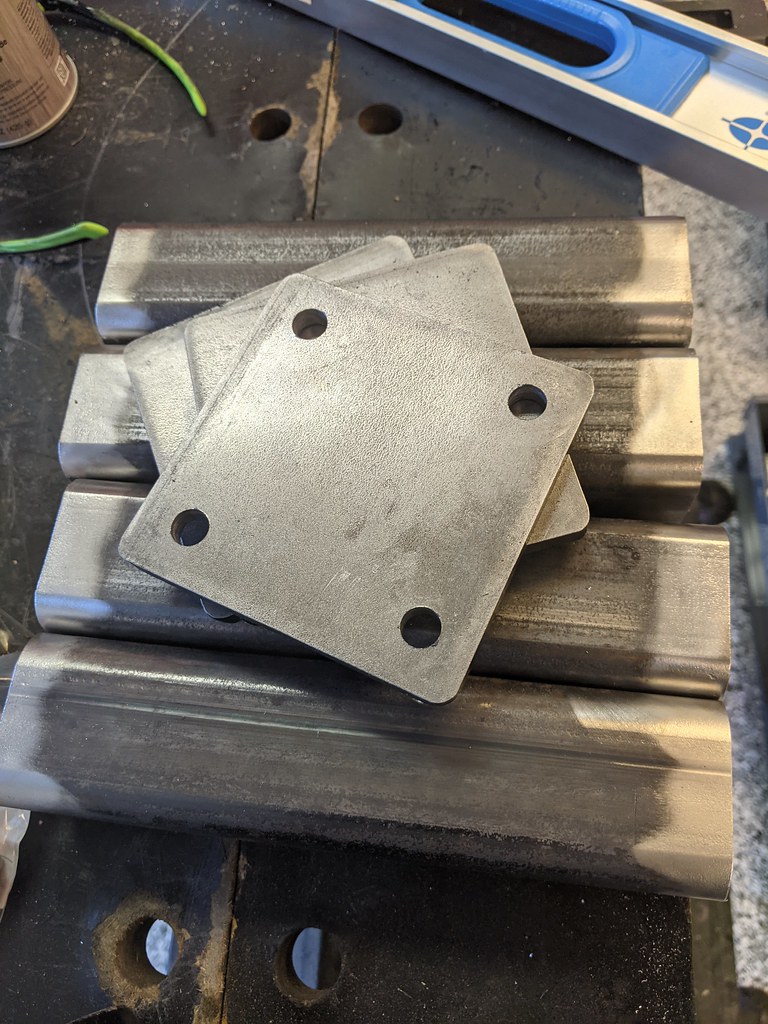

I accomplished this by cutting 4 9" lengths of 2x2x1/4" and 4 4x4" 3/16" plates with holes for the wheels. I used the grinder to round the corners.

I'm glad I didn't weld these wheels on:

I was pretty confident the 1/4"+3/16" plates and tubing was going to be stout enough for this application, but I actually tested the first corner by rolling the table up on it after I made it just to be sure (I was also nervous about my welds... I just don't have much experience!).

It is def. stout enough!

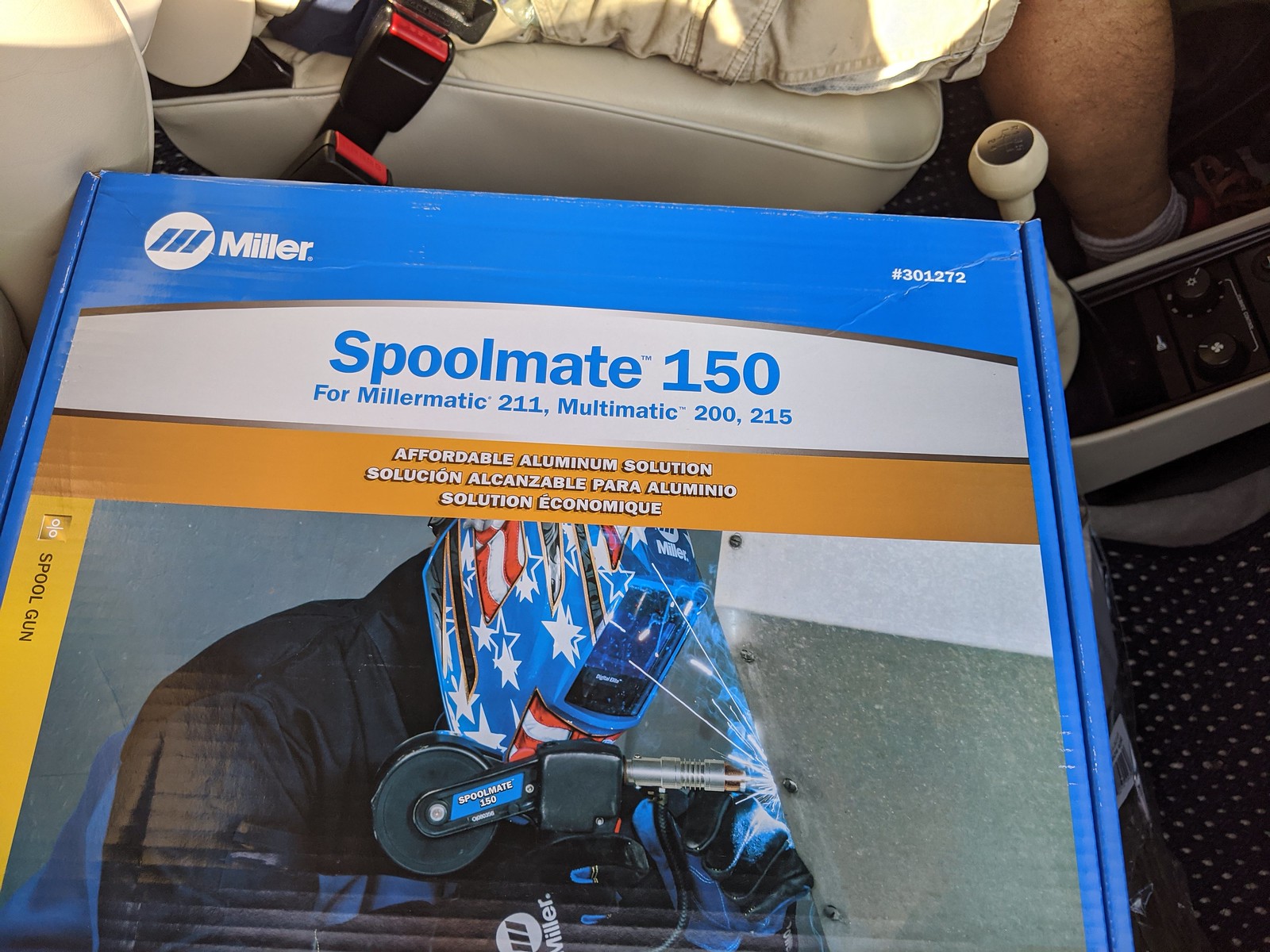

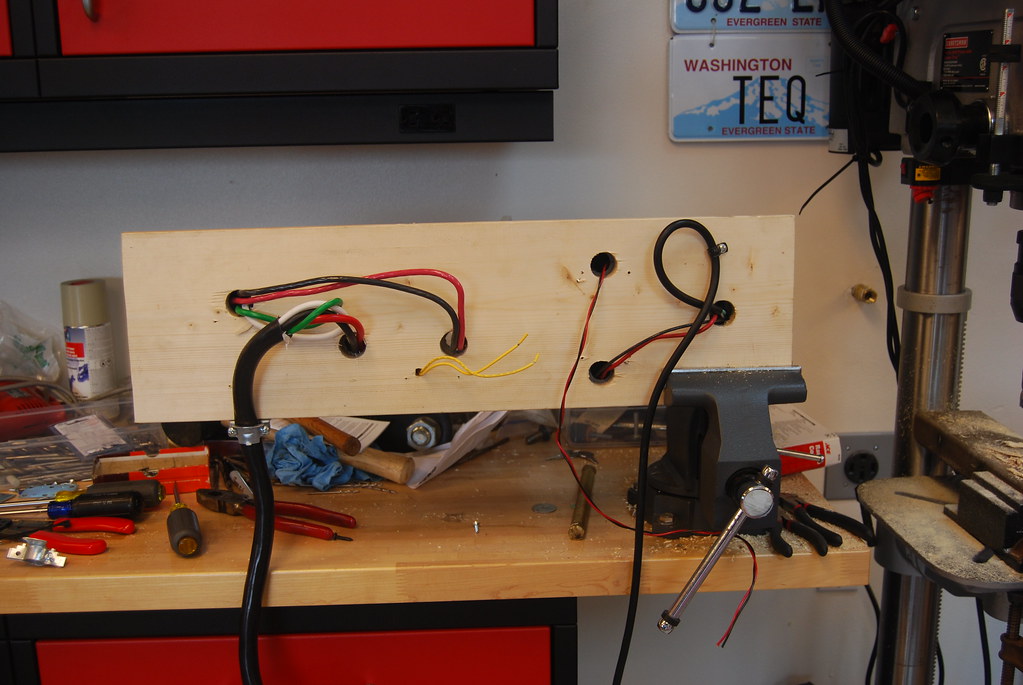

For giggles, and because I wanted to practice with much thinner gauge sheet metal I made a little tray. I used my 1/2" planks as a brake since I don't have one. That was fun. I discovered that my Miller 211 is not really capable of welding 24ga sheet metal. I had the settings as low as I could go and even the smallest blip of the trigger caused burn-through (see corners). I'm going to remake this tray using some thicker metal and make it smaller because I did it before I decided on the plasma grate concept; that will now interfere. But I love having this little storage tray for all the tools required for grinders.

Now, what about the top?

First, I now know it was a STUPID idea to weld the heads of the bolts that secure the slats to the slats. I should have used counter-sunk holes and bolts through the bolts. Why? Because the slats are warped from the heat. Not a lot, but a few thou. They bulge right where those bolt heads were welded on. If I ever do this again, I'll do it right. But I've also proven that I can use a grinder with a flap disc, along with a straight edge to take those bulges out. It will never be perfect as a real BuildPro, but I'm now confident it will be close enough.

I am also confident the adjustment mechanism I built it will allow me to get the slats butted up against each other square, and at the perfect height. I used fine-pitched bolts and the mounting holes are oversized (allowing lateral movement).

But, how am I going to accurately drill all those 5/8" holes???

The answer happens to involve me buying a new tool I've always wanted (just because): A magnetic drill press. I have ordered a "Fein Slugger JMU 137-2QW". After much research I decided on this because a) It's German-made, b) multispeed, and c) reversible because tapping. Probably way overkill for what I'll actually use it for, but I know having a mag drill is going to be super useful. This guy on Youtube makes great use of his for all sorts of things:

https://www.youtube.com/watch?v=lvhwczDgNqI (in this video he makes a holder that lets him use it as a drill press and tube notcher).

It was this guy's videos that inspired me to drill my holes using the mag drill.

I will drill the holes in a 2"x2" grid. That's 320 holes. I'll probably regret my ambition later...

While I'm waiting for the dill to show up I ordered some 5/8" bar stock and a single 'real' BuildPro clamp so I can practice modifying my clamps to work like their system.