I'm back from Germany for one week, so I continued the build with some minor progress.

First of all, I started cleaning and prepping the pistons.

You can see just how much soot's on there - especially in the ring grooves. On multiple pistons, even some of the holes in the oil-ring-grooves were fully clogges. The attached picture is the soot from one piston.

I used old rings that I broke in half to start off...

...then I used well-done's "hideg zsíroldó = cold degreaser" - a strong cleaning agent + elbow grease; smoothened the top of the pistons with a dremel tool, then finished off with the ultrasonic cleaner.

Off: does anyknow know what these random pieces of a different metal (steel?) are in the pistons? These are OEM Nural B35 E32 pistons.

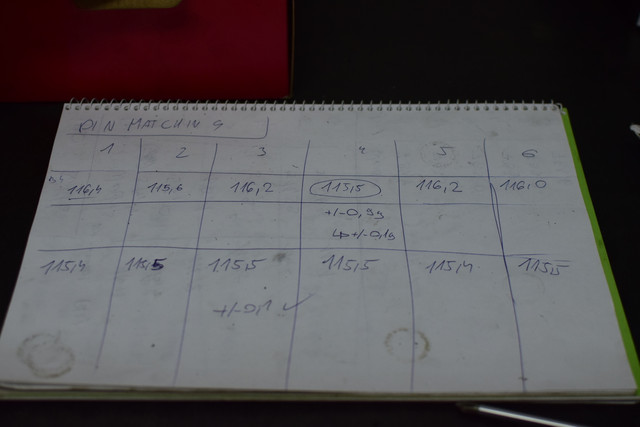

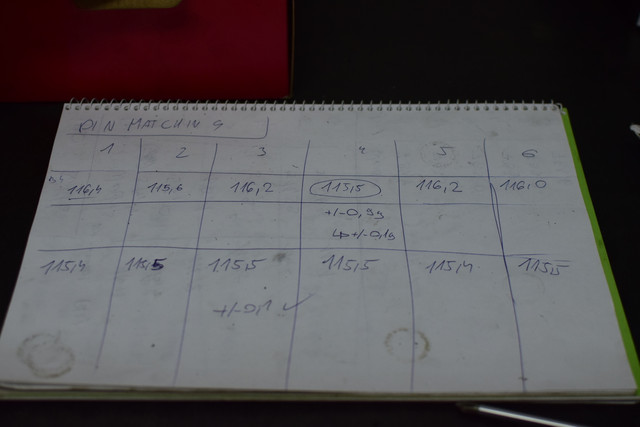

I gave the wrist pins a quick polish, just to clean them a bit; then weight matched them to +/-0.05grams by sanding the inside of them.

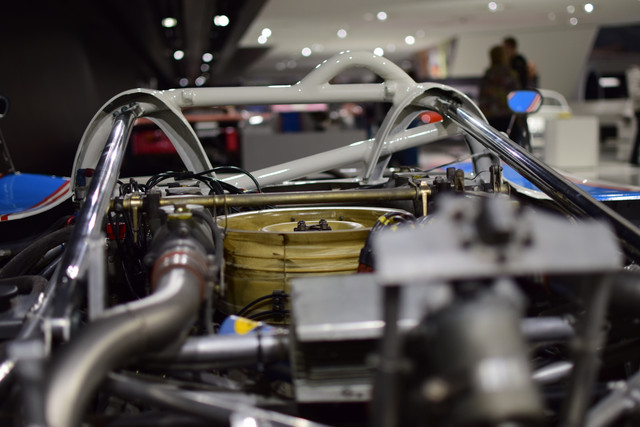

I also prepped the pistons for cerakote, and I cleaned my engine block thoroughly, now completely ready for assembly.

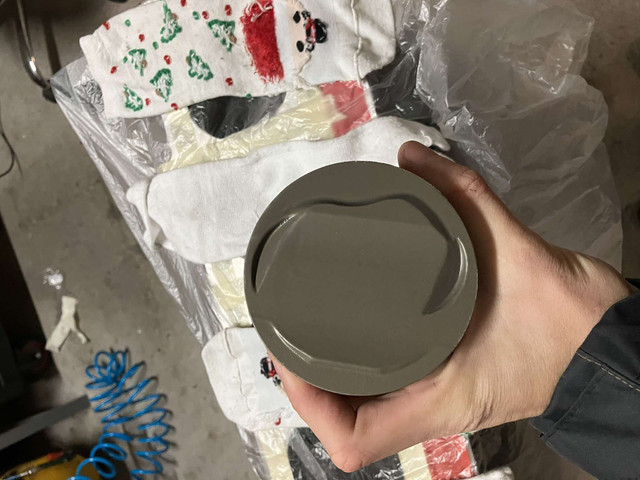

I sprayed the top of the pistons using cerakote C-186; they are drying right now.

I'll take some pictures on tuesday, we will see how it went.

I used a 1.4mm HVLP gun, because I did not want to buy another gun just for this.

Turned down the pressure to 25psi, full fan, and low material flow. It's was my first time ever with a gun, but it went really smoothly. The material is quite easy to apply. I apply one heavy, and one lighter coat. I preheated the pistons to 40C.

I'm headed back to Germany on wednesday for a final trip this year; once back, I'll move on to cerakote the skirts. While drying, I'll weight match the rods, then I can finally start the engine assembly.

I only have one camera (and only a potato phone):

If anyone is interested, what you like to see more?

Detailed pictures with comments, or a time-lapse of the build?