More forward progress made today. The clutch reinforcement plate was received and installed. Another issue from the PO found and corrected, the clutch master cylinder was installed on the wrong side of the pedal bracket. I discovered this after installing the plate, and pressing the pedal to the floor. There was a crunch sound and it appeared the rod had bent. After I took the linkage apart and moved it to the other side of the pedal bracket, it cycles smoothly now. Hopefully nothing internally broke, guess I'll find out once I finally get the transmission installed and start bleeding the system.

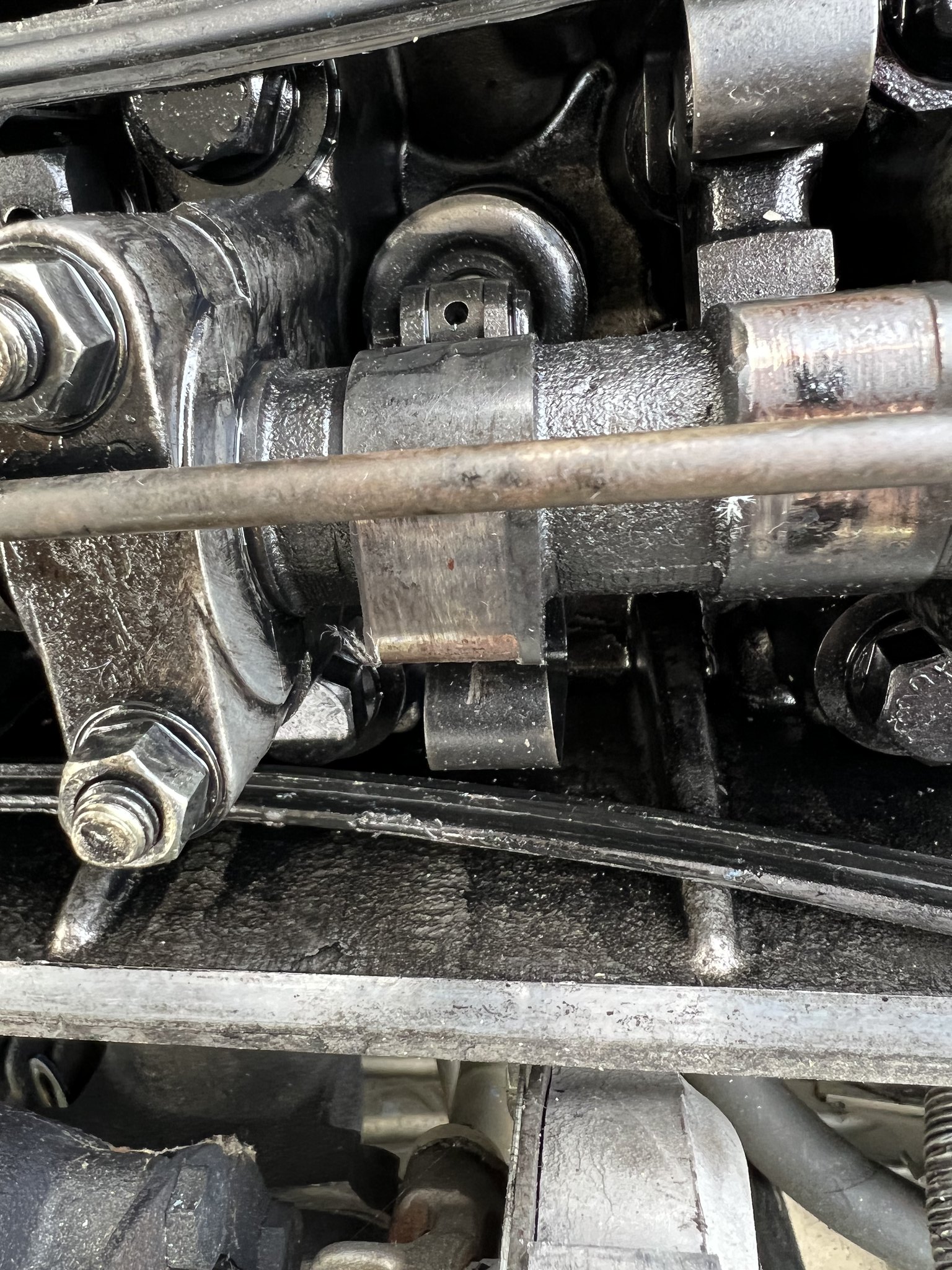

I spent some time looking at the injection pump and comparing it to the breakdown on realoem. You are correct, I am missing some pieces, the thumbwheel being among them. Interestingly enough some of that assembly is present. I will start looking for parts and try to get that resolved. In staring at the pump with a flashlight, I noticed two brown wires hanging down towards the engine oil pan. When I first saw these wires, I had assumed they were for the oil level indicator sensor in the oil pan, but I am now fairly certain they are the two missing wires that link the R118 injection pump to the ECU. Perhaps I need to follow up on the special #4 injector. I'll get a picture of the connector this afternoon, but in the meantime I found a picture I took a few days ago that shows these two wires on the left side of the picture next to where the oil dipstick mounts to the block:

Vacuum pump came in, I've just got to find or purchase the mounting hardware to get that wrapped up, then I can continue addressing the wiring nightmare in the engine bay. Some other things that need to be addressed are to find the bracket that mounts on the end of the starter, get the starter tested, and continue trying to figure out what else is missing. Accelerator pedal bushings are beyond gone, I'll get some delrin ones placed on order. . . its all the small stuff, but there is one huge glaring issue that I need to address: The flywheel and clutch.

Yesterday, I took the only flywheel that came with the car (that looked like it would fit correctly) to the machine shop. I was asking for 3 things: (1) clean the metal up using soda blasting or some other type of non-abrasive media. (2) use the factory flexplate as a template to drill holes and transfer the 6 tachometer pins into the new flex plate (3) skim the clutch contact surface to clean it up as best they are able.

I was very surprised that they refused all 3 requests. I was told this is a dual mass flywheel (which I knew it was prior to my visit), but consequently it is a scrap item and cannot be surfaced or blasted. There is a fabrication machine shop at the other end of town that I will be visiting today, to see if they will entertain my request. My thoughts are drilling and reaming some blind holes using a template are among the most basic of machinist tasks, and one I would most certainly do myself if I had access to a large enough drill press or vertical mill.

If I am unable to have this flywheel modified, I am back to this journeys origin regarding the clutch/transmission installation. I've inquired at the usual sources regarding the factory 524td flywheel, but it seems to be out of stock everywhere. The other option is to order the Valeo single mass flywheel kit from ECStuning, but I would need to find someone to drill and ream the blind holes for the 6 pins. Does anyone have any recommendations?