Turbo ETA build

Re: Turbo ETA build

I should do that. I feel like it's running better than the 2007 build did with the blow through AFM, motronic and an undersized intercooler.

If this car ends up for sale, which is the plan at some point, a dyno sheet is a nice bonus.

If this car ends up for sale, which is the plan at some point, a dyno sheet is a nice bonus.

Re: Turbo ETA build

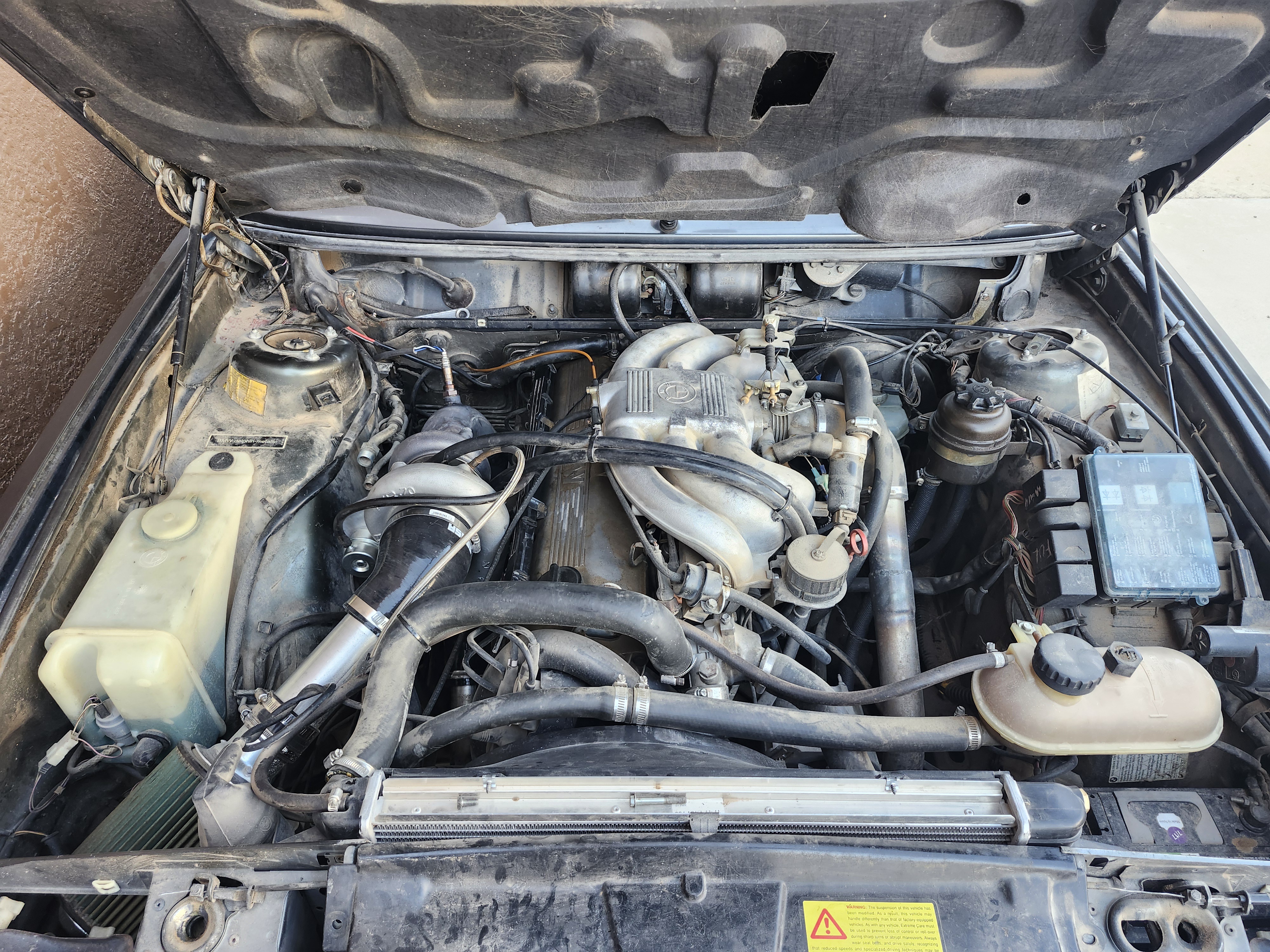

It's been a bit over a year now, I just realized that the other day. Still holding out with this small turbo at low boost, not pushing my luck and enjoying it for what it is. A dirty, dusty daily driver:

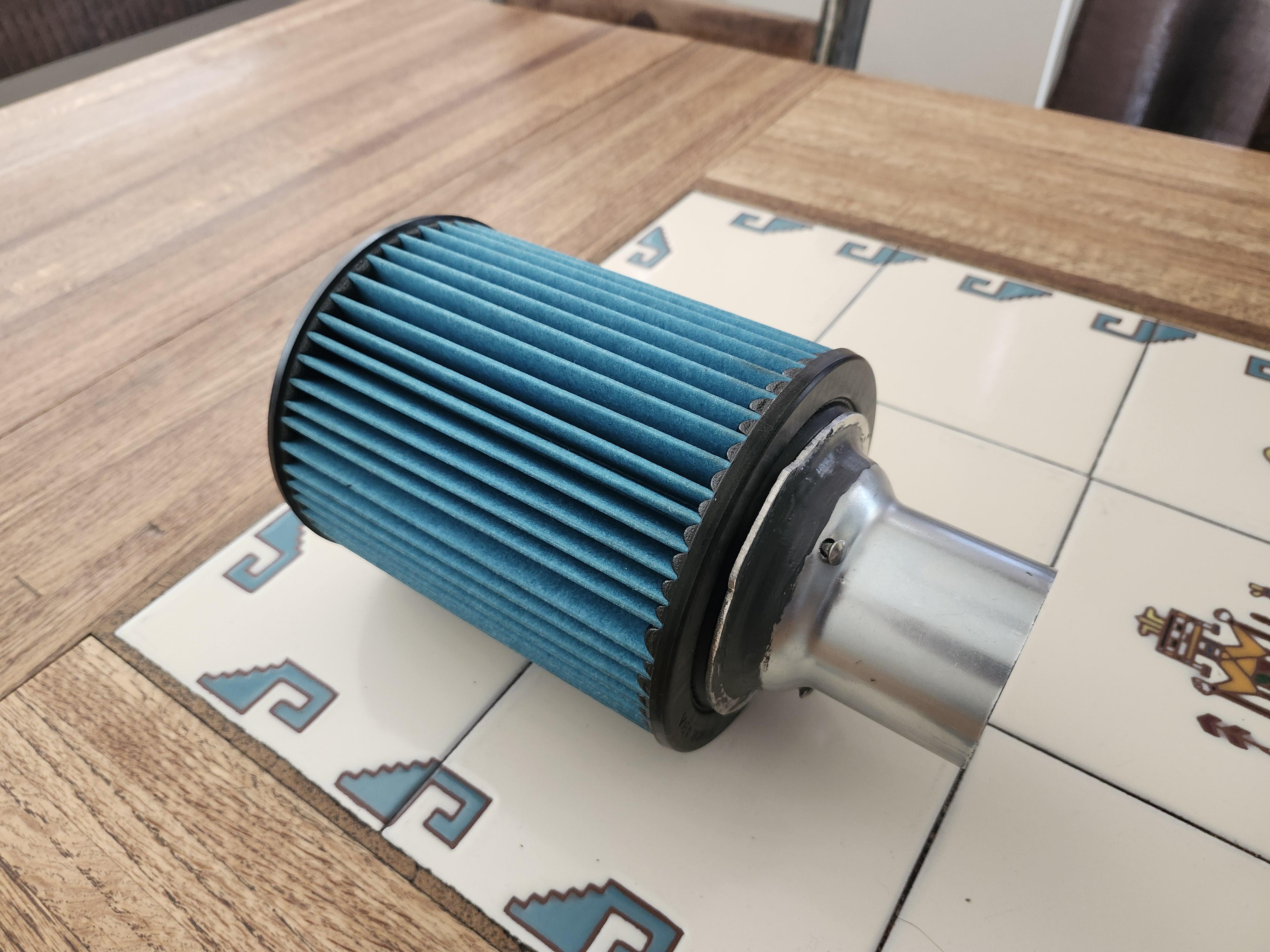

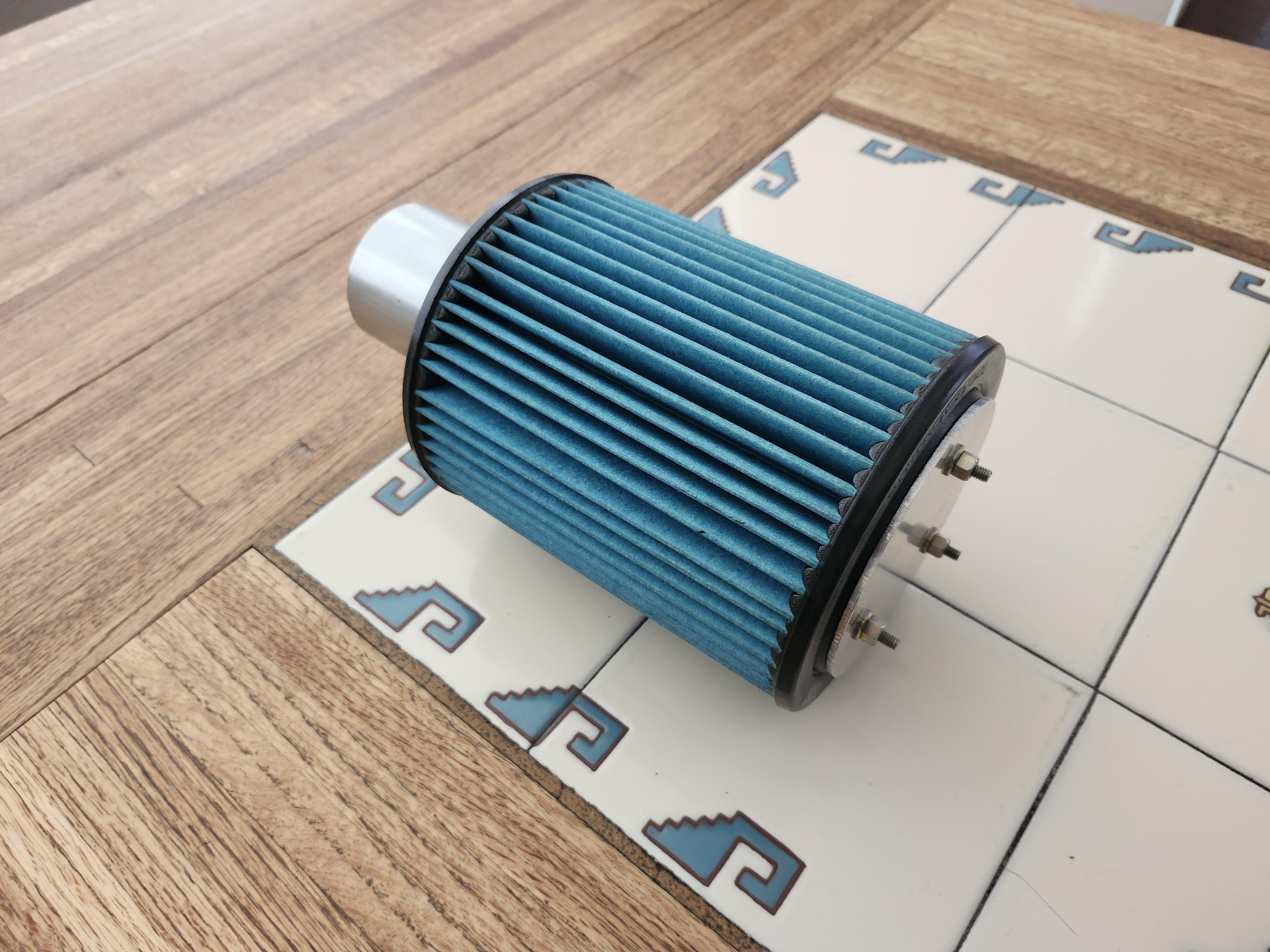

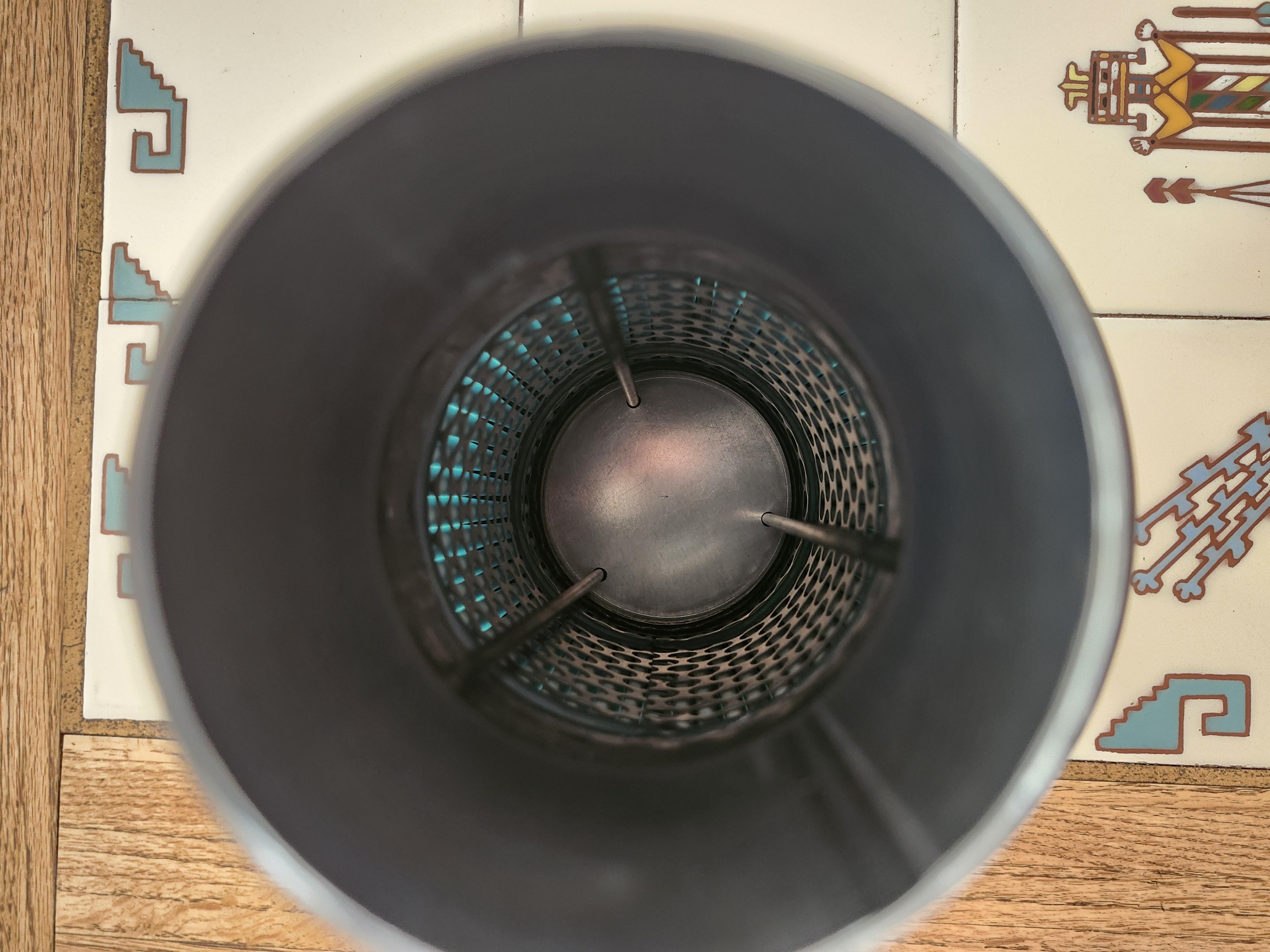

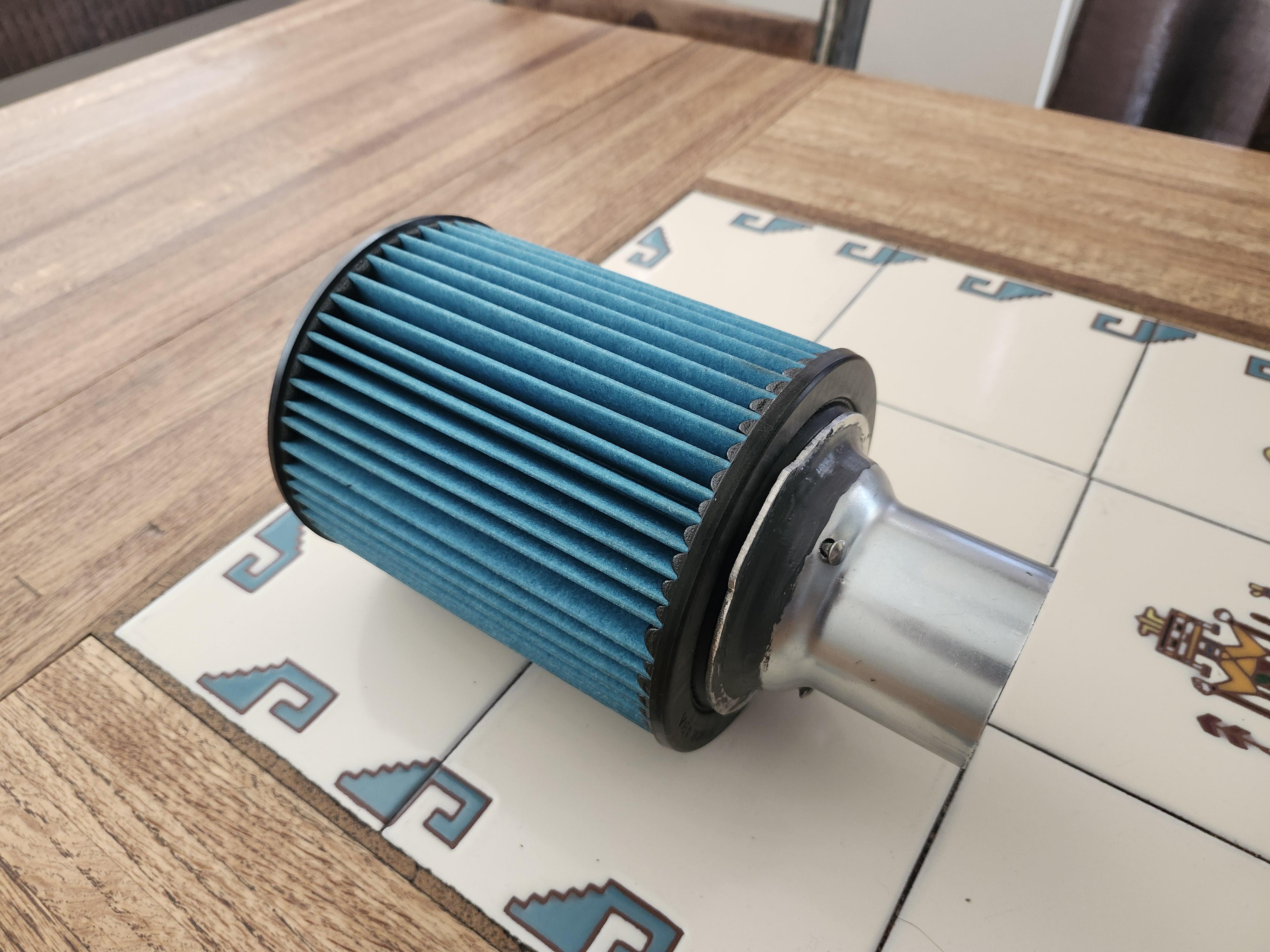

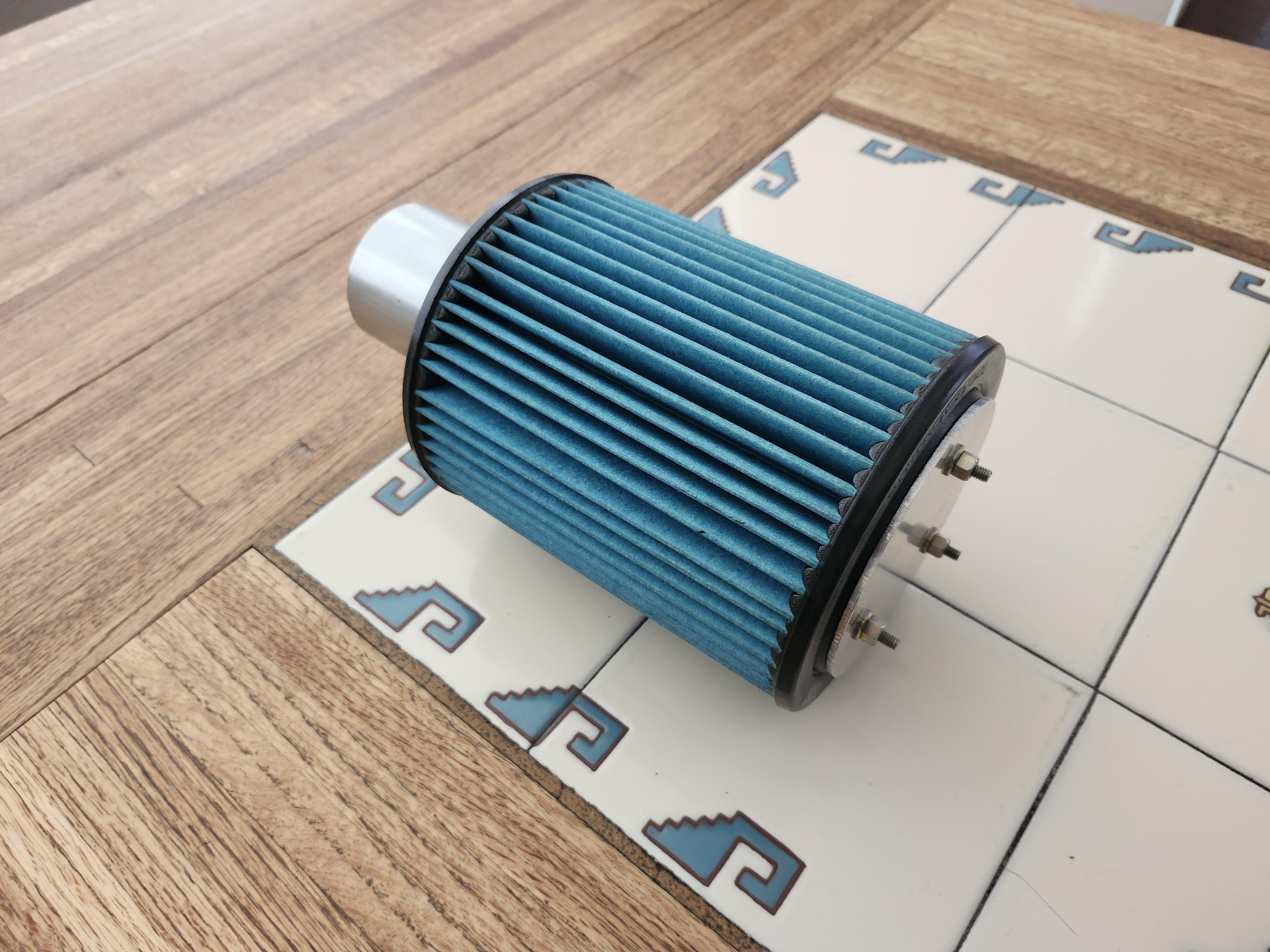

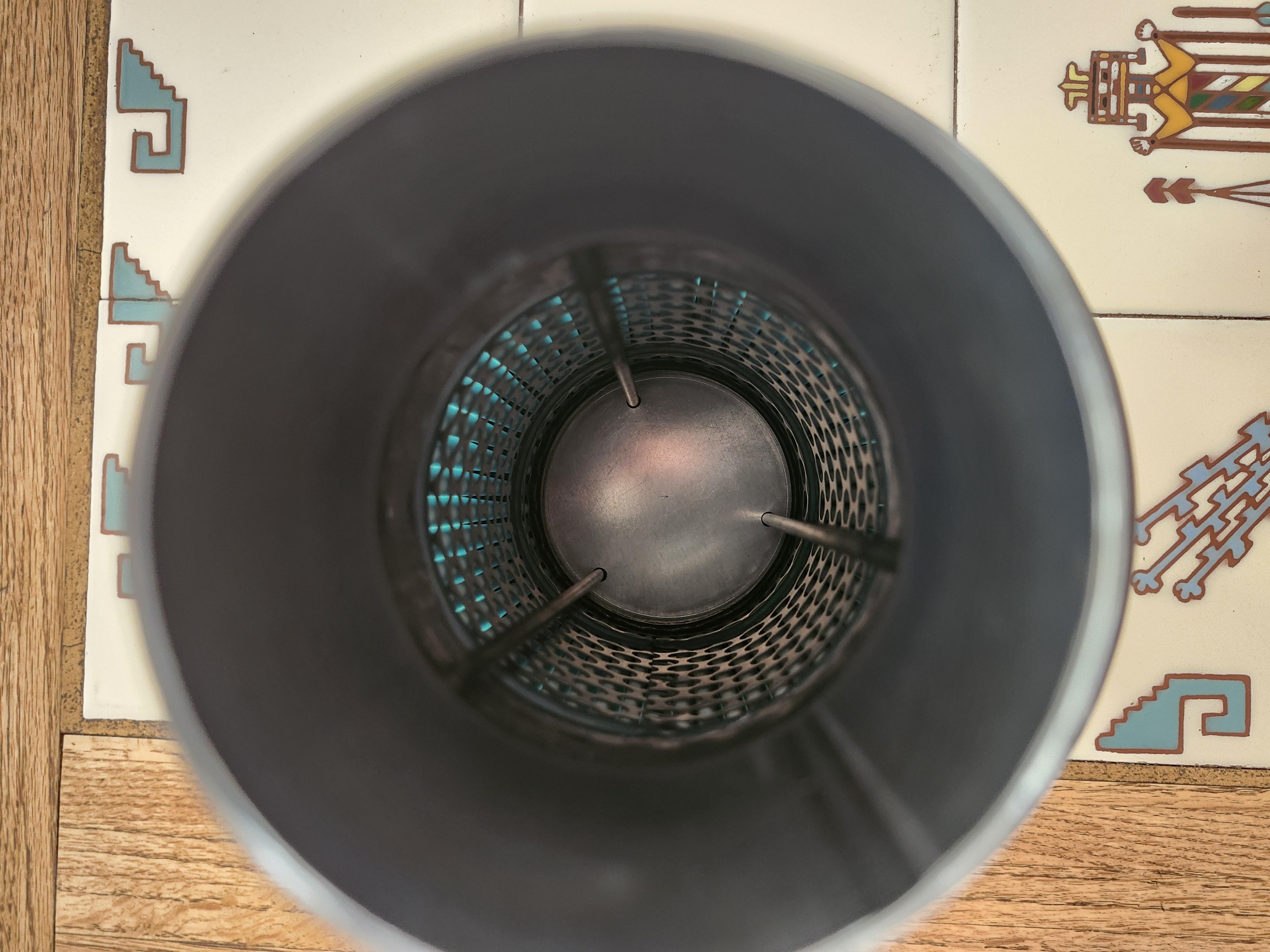

I did improve the air filter. I had a paper filter element from a dodge, perhaps a neon, which fit well and I assumed would work adequately. Unfortunately with the moon dust we have out here it proved to be insufficient. It filters out most of it but I still find dust upstream. This is not acceptable, so I constructed this apparatus around a Honda Element/CR-V air filter:

It is a large, cylindrical element consisting of a perforated metal core wrapped with a copius amount of thick, pleated, oiled filter media. The inner diameter is about 81mm and it is open on both ends, necessitating an end cap. I had some straight pull spokes laying around so I used those to hold the assembly together and clamp down against the sealing surfaces on both ends. These are available cheaply at any honda dealer and will support a butt load of air flow. The lightly oiled filter media will catch anything and everything, even better than a high quality paper filter. I highly recommend it.

I did improve the air filter. I had a paper filter element from a dodge, perhaps a neon, which fit well and I assumed would work adequately. Unfortunately with the moon dust we have out here it proved to be insufficient. It filters out most of it but I still find dust upstream. This is not acceptable, so I constructed this apparatus around a Honda Element/CR-V air filter:

It is a large, cylindrical element consisting of a perforated metal core wrapped with a copius amount of thick, pleated, oiled filter media. The inner diameter is about 81mm and it is open on both ends, necessitating an end cap. I had some straight pull spokes laying around so I used those to hold the assembly together and clamp down against the sealing surfaces on both ends. These are available cheaply at any honda dealer and will support a butt load of air flow. The lightly oiled filter media will catch anything and everything, even better than a high quality paper filter. I highly recommend it.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

That should work well! Looks big enough to be a truck filter.

Re: Turbo ETA build

It's huge considering it's original application. Much more appropriate on something like this which requires far greater air flow than the 2.4l Honda.

I was surprised to find that I had to make adjustments to the fuel table with the new filter. Had to add fuel especially under boost. The old filter was apparently undersized to the point of inefficiency.

I really should dyno it just for kicks. Minimum 230 rear wheel, I would guess 250 max as it sits now at .5 bar. As Todd mentioned long ago, they make a predictable amount of power, something like 11rwhp per pound of boost. I guess the question is what kind of boost I want to run it at. Perhaps .8 bar would be interesting, if the clutch will hold.

.8 bar would be about 11.5 psi. If the predicted power is achieved it would make about 285 rear wheel, comparable to a strong S54. I know this turbo is increasingly inefficient at higher boost but it'll certainly make the boost.

I've also been thinking about swapping the turbo cam back in. That head is complete and ready to install, would definitely make for a more interesting dyno than a re-run of the original.

I was surprised to find that I had to make adjustments to the fuel table with the new filter. Had to add fuel especially under boost. The old filter was apparently undersized to the point of inefficiency.

I really should dyno it just for kicks. Minimum 230 rear wheel, I would guess 250 max as it sits now at .5 bar. As Todd mentioned long ago, they make a predictable amount of power, something like 11rwhp per pound of boost. I guess the question is what kind of boost I want to run it at. Perhaps .8 bar would be interesting, if the clutch will hold.

.8 bar would be about 11.5 psi. If the predicted power is achieved it would make about 285 rear wheel, comparable to a strong S54. I know this turbo is increasingly inefficient at higher boost but it'll certainly make the boost.

I've also been thinking about swapping the turbo cam back in. That head is complete and ready to install, would definitely make for a more interesting dyno than a re-run of the original.

Re: Turbo ETA build

I found this thread trying to figure out what flange size the 524td manifold I have sitting on the shelf is. Killer work- this reminds me of old r3v

Re: Turbo ETA build

Best to measure it, there are t25 and t3 varieties. The most common is the AGR manifold with the t3 flange.blue91lx wrote: Jul 13, 2024 9:13 AM I found this thread trying to figure out what flange size the 524td manifold I have sitting on the shelf is. Killer work- this reminds me of old r3v

Re: Turbo ETA build

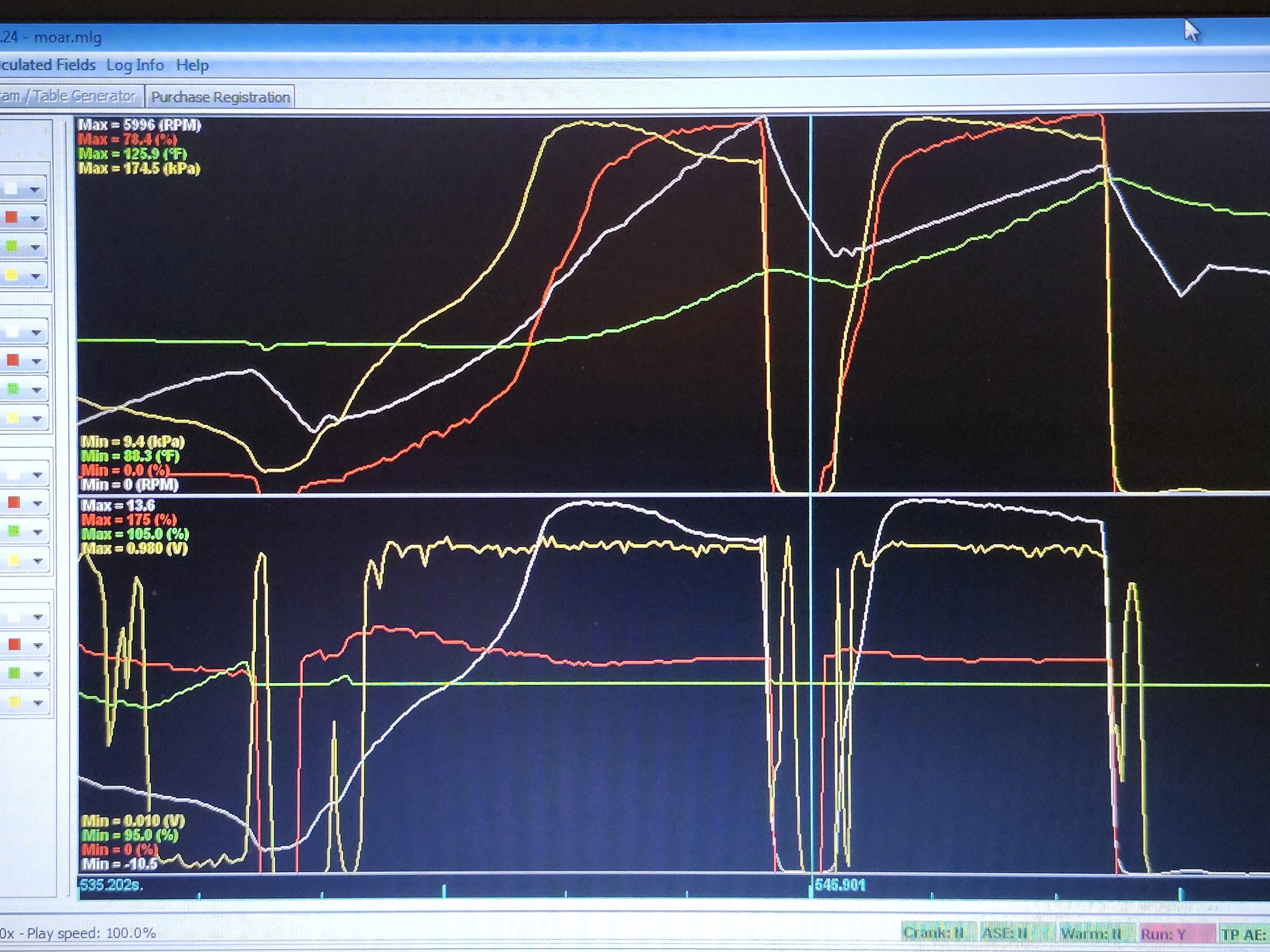

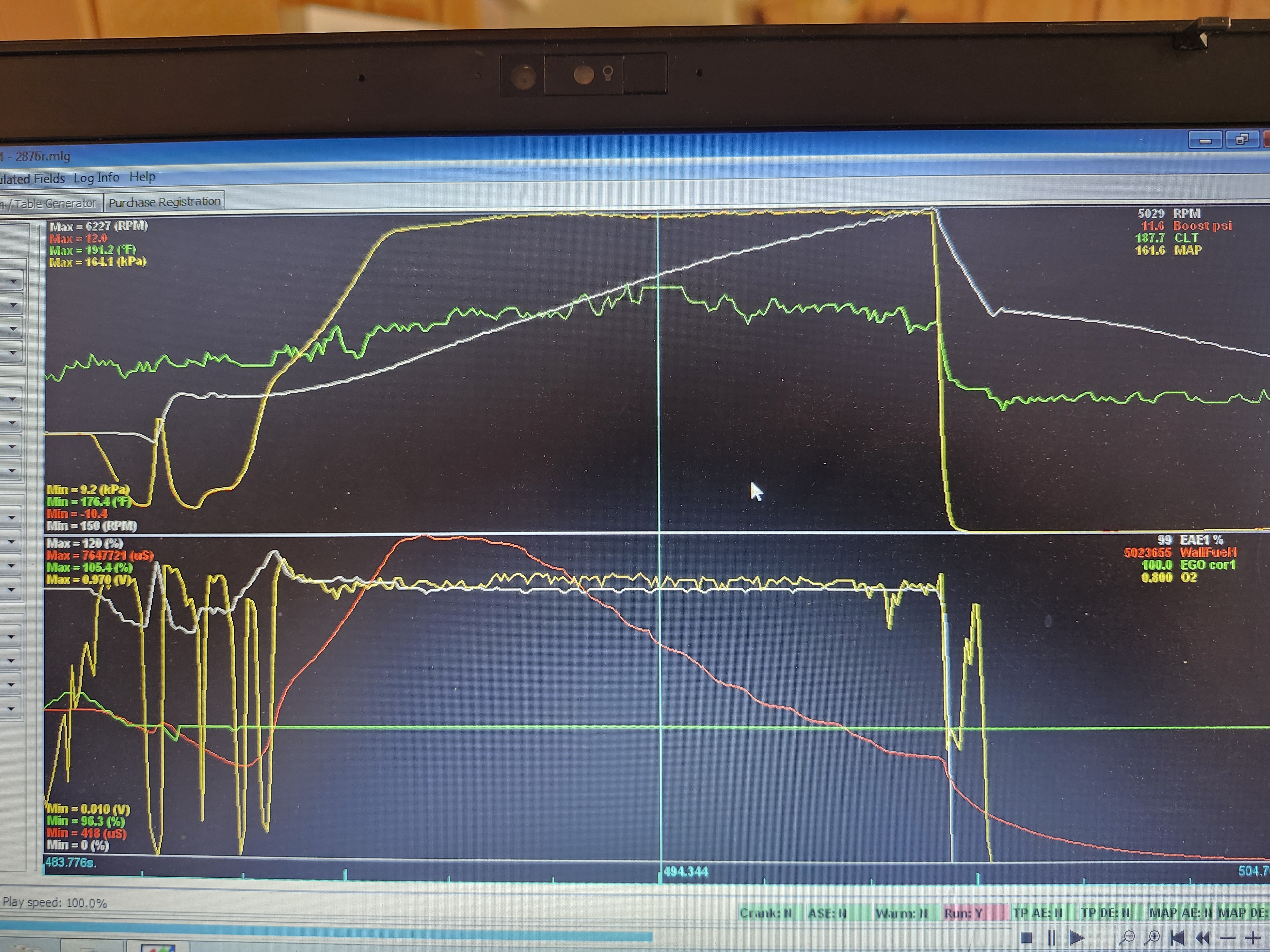

I decided it's time to push my luck a little bit. I figure, if I'm going to swap the head out and put the turbo cam back in, I will be replacing the head gasket either way. Might as well push some more boost through and see how much the stock clutch and head gasket will withstand.

The option at hand is a garrett 12-14 psi wastegate actuator. I removed it from my GT2971R that's been literally sitting on top of my dresser for the last year and bolted it onto the GT2560R. Minor slotting of the bolt holes was required. I prefer this over the ball and spring MBC as the MBC always spikes on spoolup and settles toward equilibrium. A higher pressure wastegate with nothing interfering with the signal line operates more consistently.

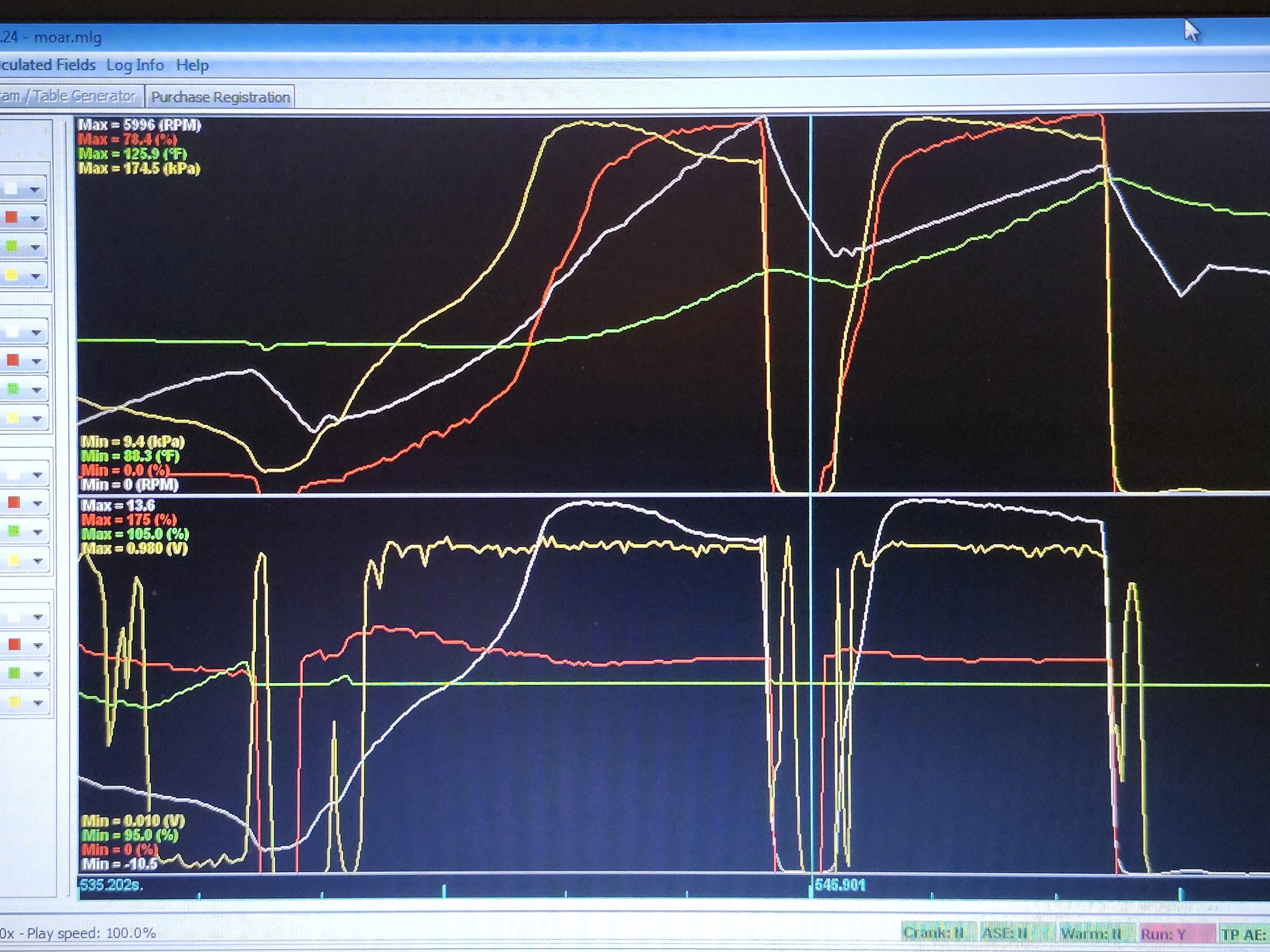

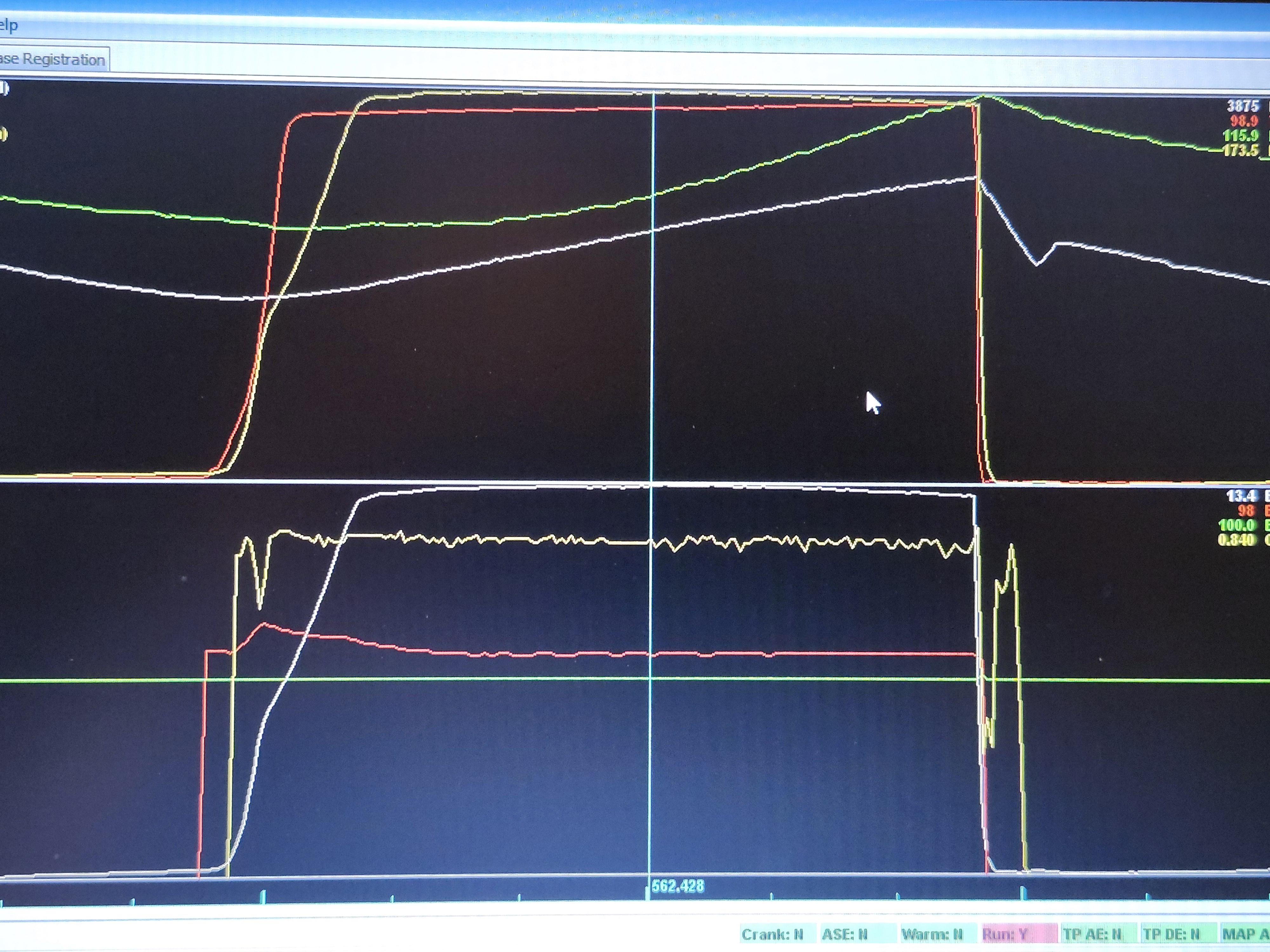

The tension on the actuator rod is adjustable, and I may dial it down a bit, as it is currently hitting a maximum of ~175 kpa, or 13.6 psi above atmospheric. This little Garrett is doing the best it can but it does drop off a bit toward the top end, down to about 10.5 by 6k. The pull from the bottom end and midrange is excellent, and despite the drop in boost the top end is not bad either. I don't need to short shift it, it definitely pulls all the way up.

We'll see how it does. The datalog shows only wheelspin, no clutch slippage. This is the same stock 528e clutch that I took out of a parts car about 15 years ago and had sitting on my garage floor until installation late last year. Slipped badly at first, and I was bummed, but after a few drives it came alive again and it's been great since.

The option at hand is a garrett 12-14 psi wastegate actuator. I removed it from my GT2971R that's been literally sitting on top of my dresser for the last year and bolted it onto the GT2560R. Minor slotting of the bolt holes was required. I prefer this over the ball and spring MBC as the MBC always spikes on spoolup and settles toward equilibrium. A higher pressure wastegate with nothing interfering with the signal line operates more consistently.

The tension on the actuator rod is adjustable, and I may dial it down a bit, as it is currently hitting a maximum of ~175 kpa, or 13.6 psi above atmospheric. This little Garrett is doing the best it can but it does drop off a bit toward the top end, down to about 10.5 by 6k. The pull from the bottom end and midrange is excellent, and despite the drop in boost the top end is not bad either. I don't need to short shift it, it definitely pulls all the way up.

We'll see how it does. The datalog shows only wheelspin, no clutch slippage. This is the same stock 528e clutch that I took out of a parts car about 15 years ago and had sitting on my garage floor until installation late last year. Slipped badly at first, and I was bummed, but after a few drives it came alive again and it's been great since.

-

Nebraska_e28

- Beamter

- Posts: 9058

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Turbo ETA build

How far to the local dyno?

The graph looks pretty solid overall.

The graph looks pretty solid overall.

Re: Turbo ETA build

About 25 miles, hopefully they're still there. It's been a while...

Re: Turbo ETA build

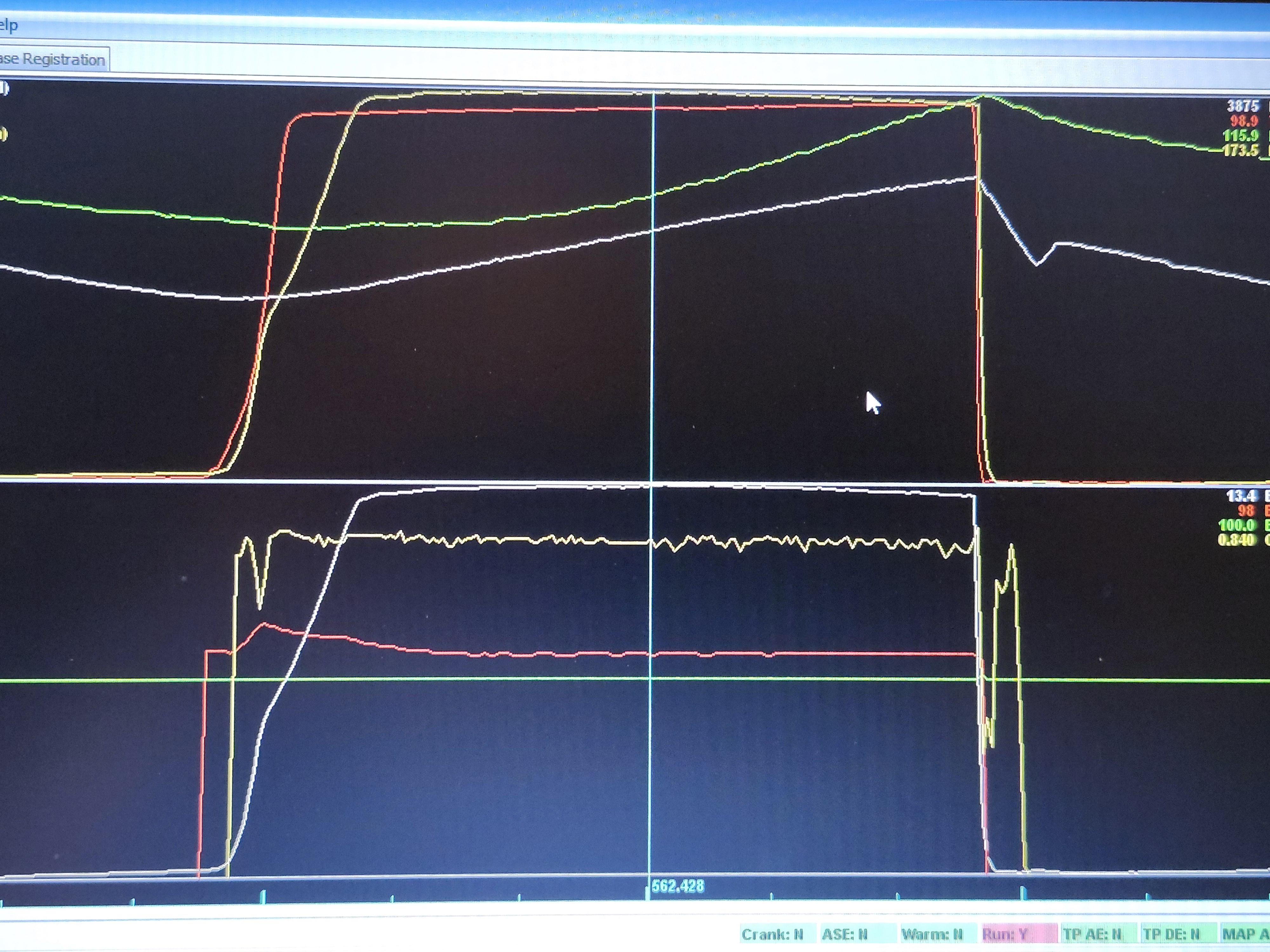

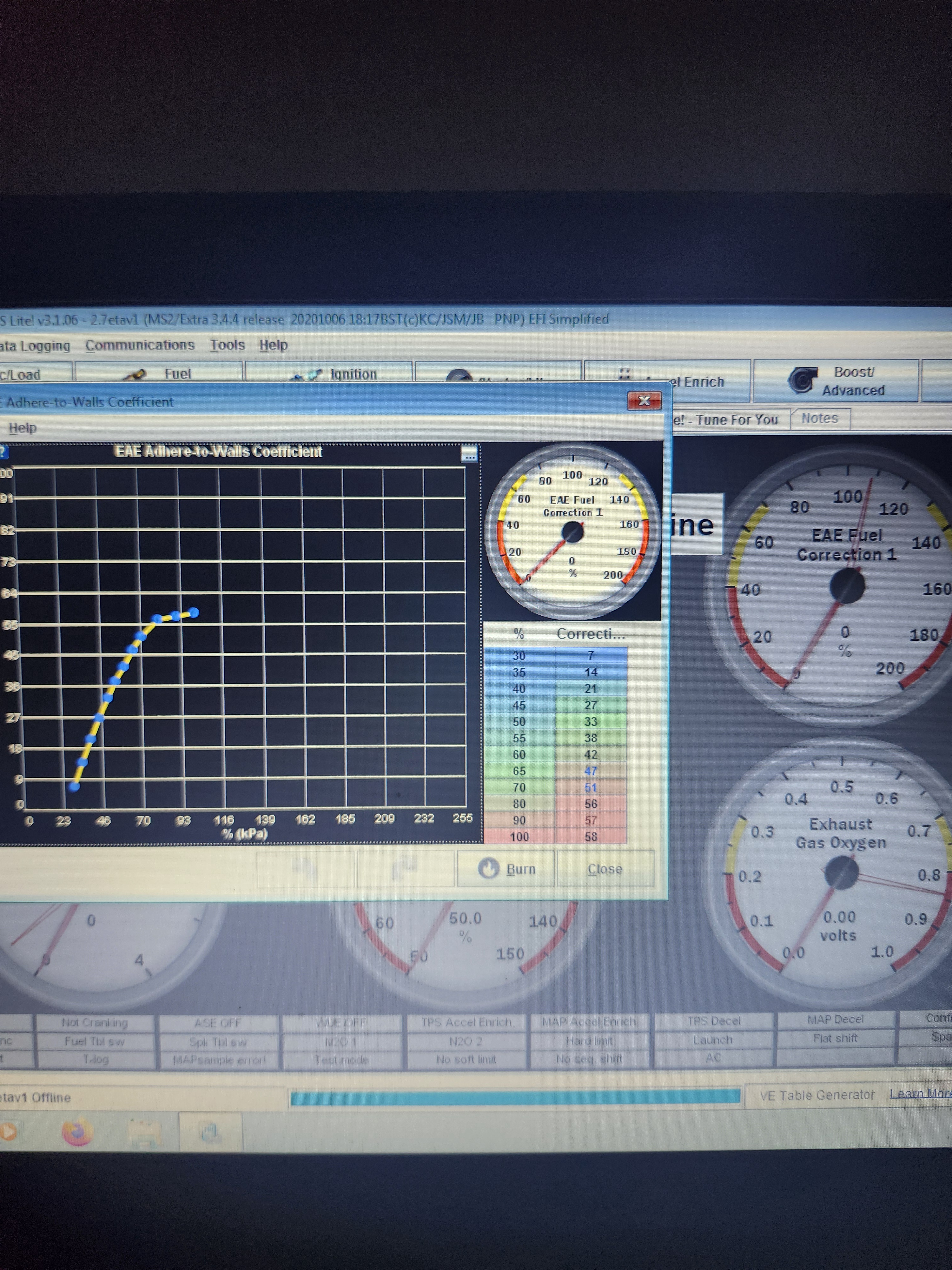

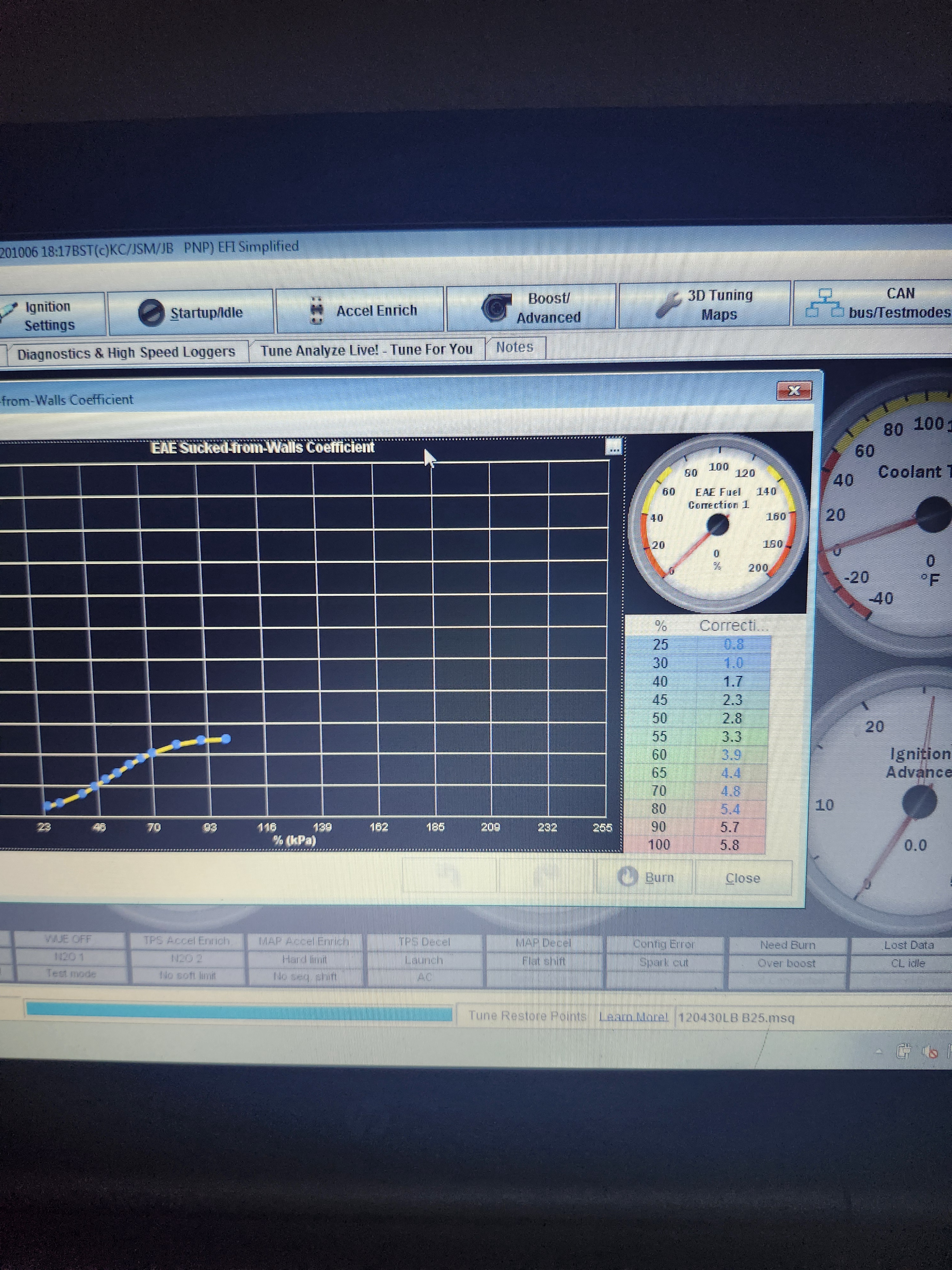

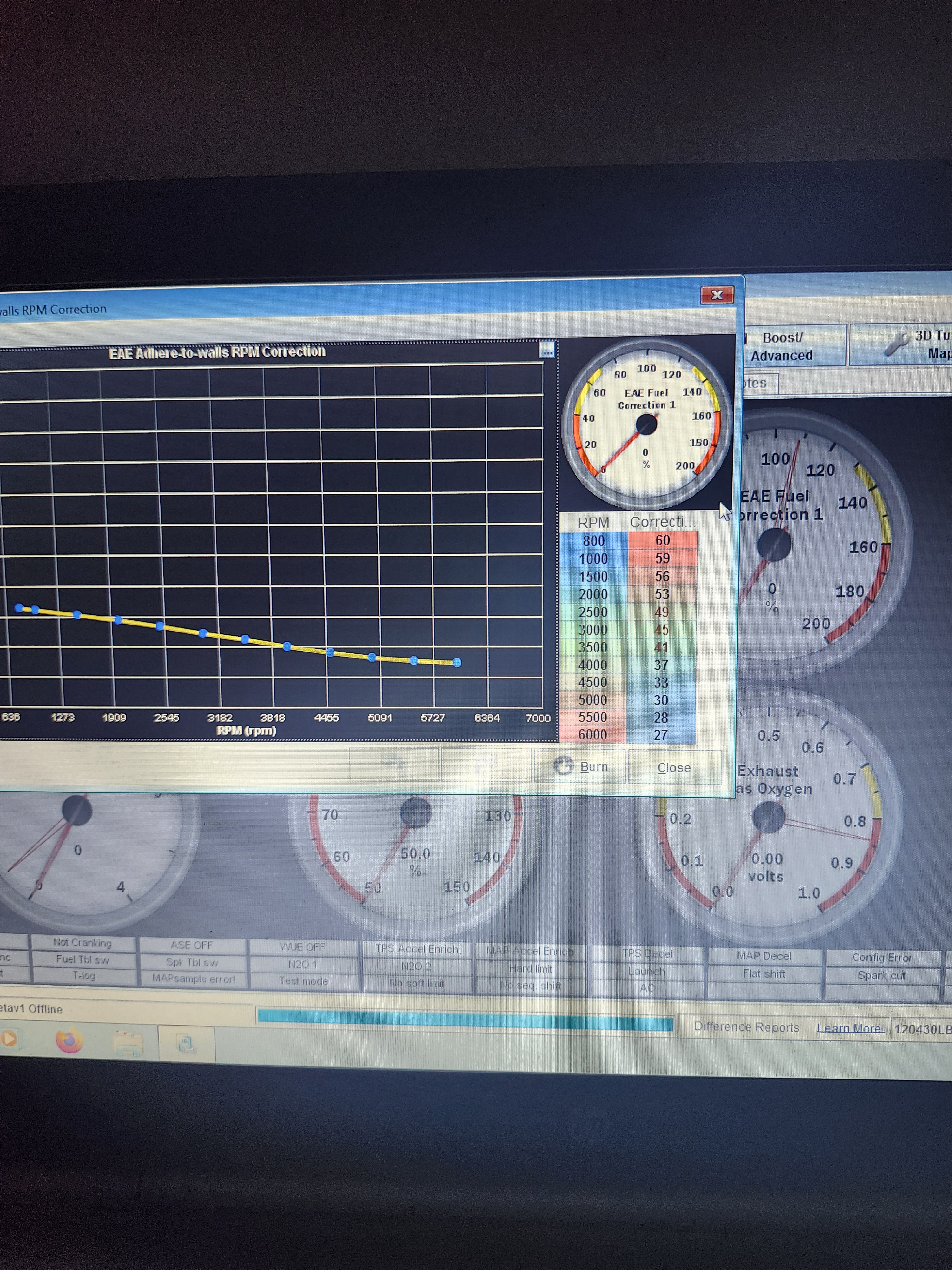

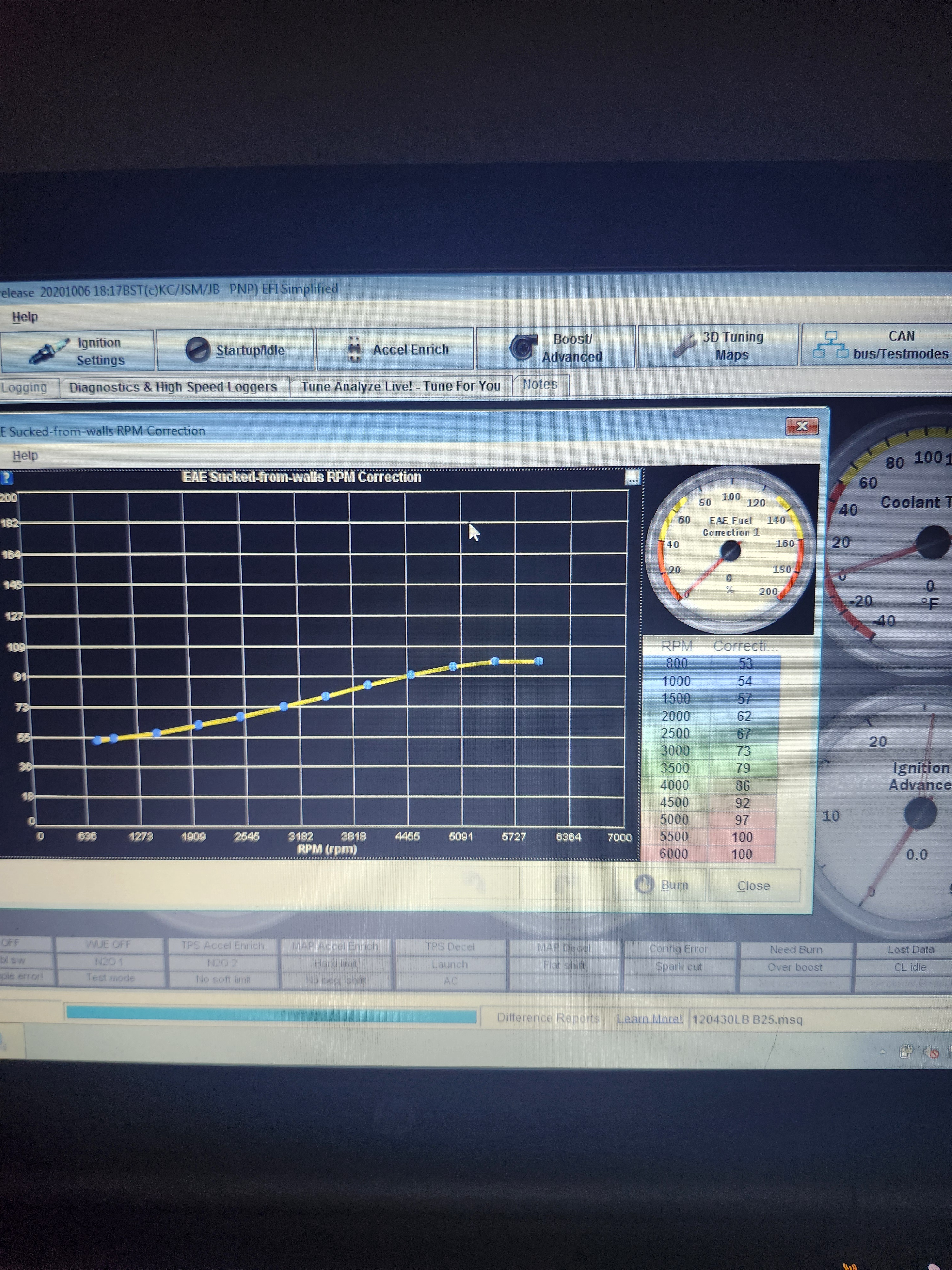

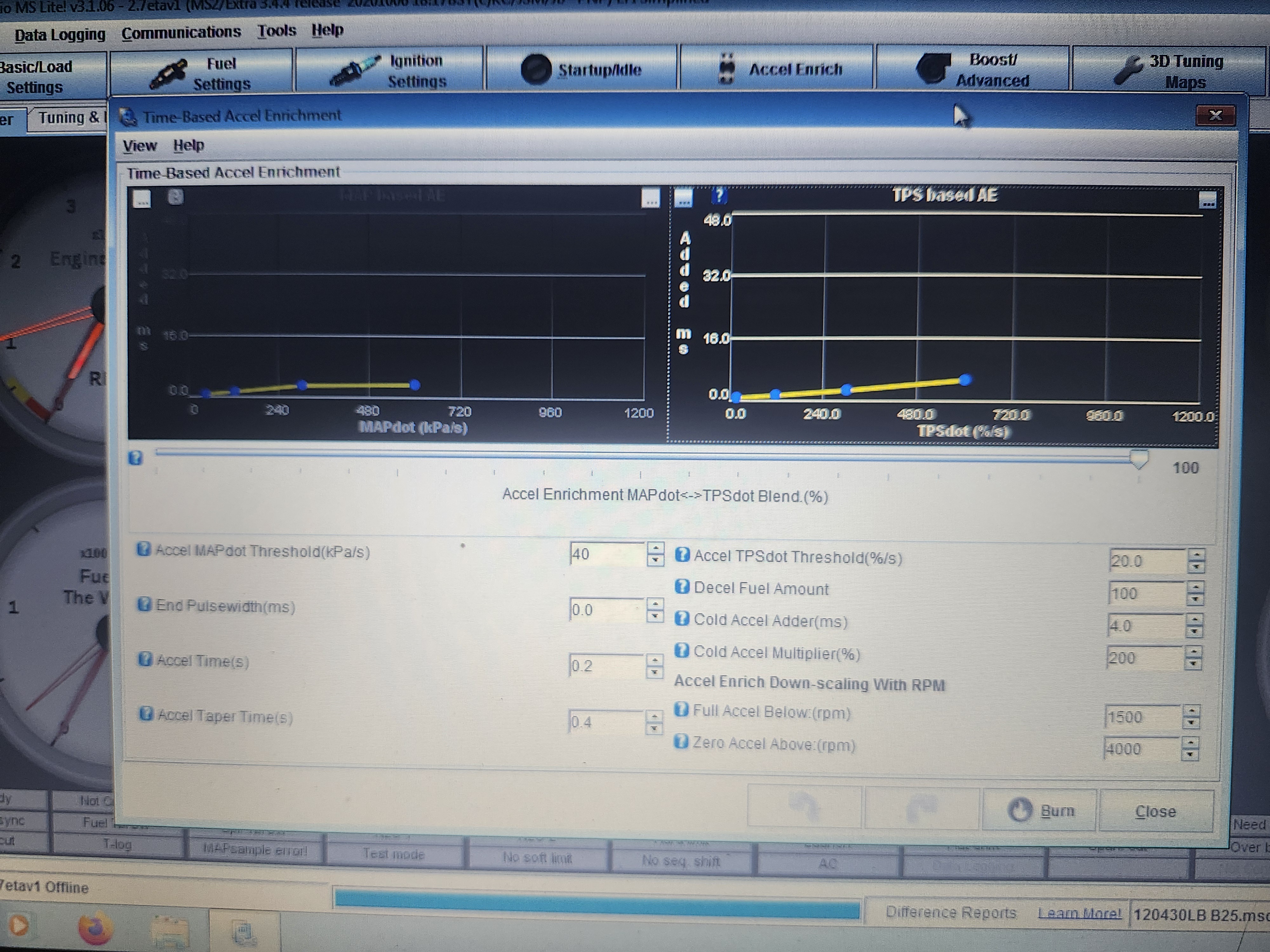

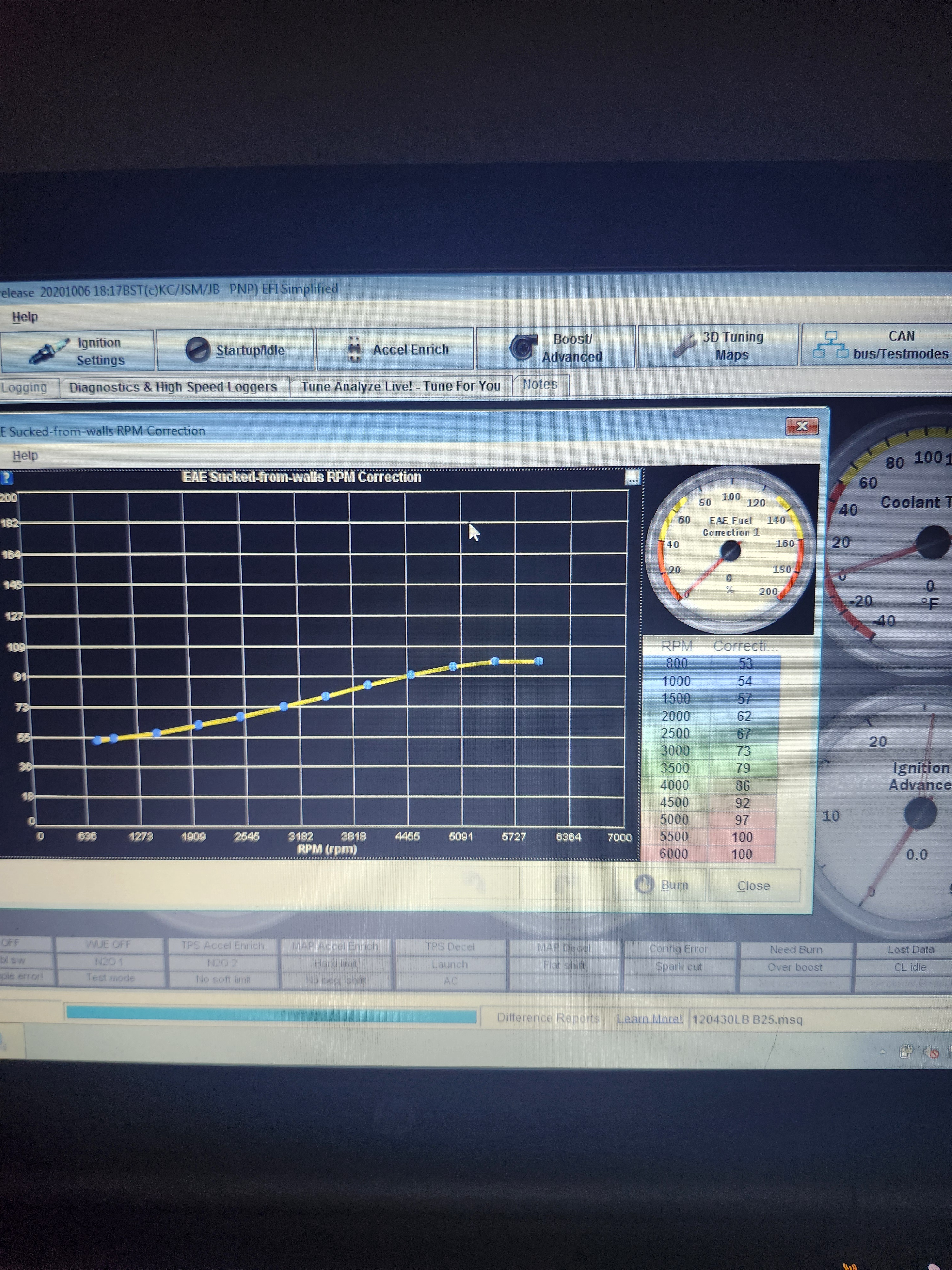

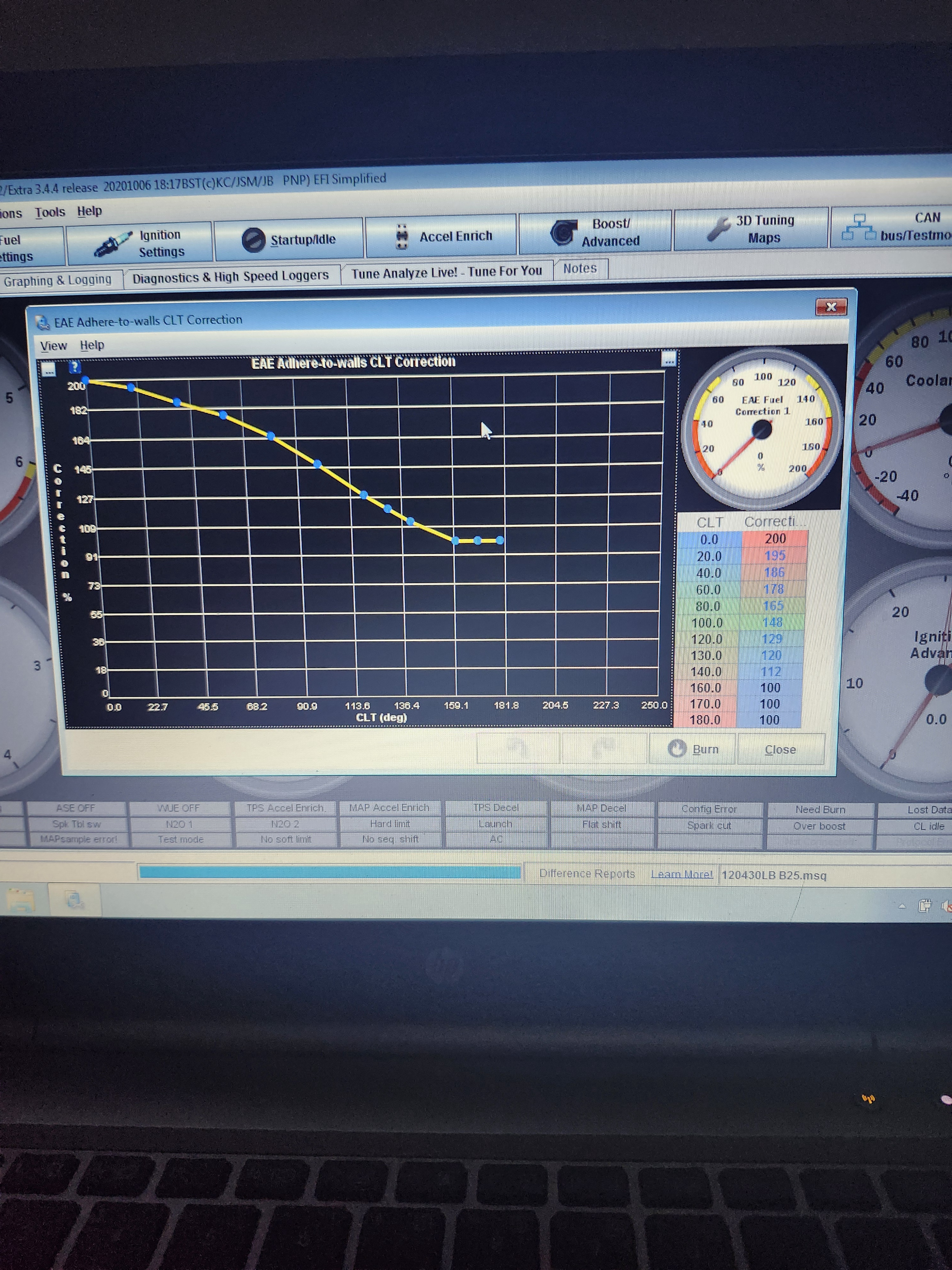

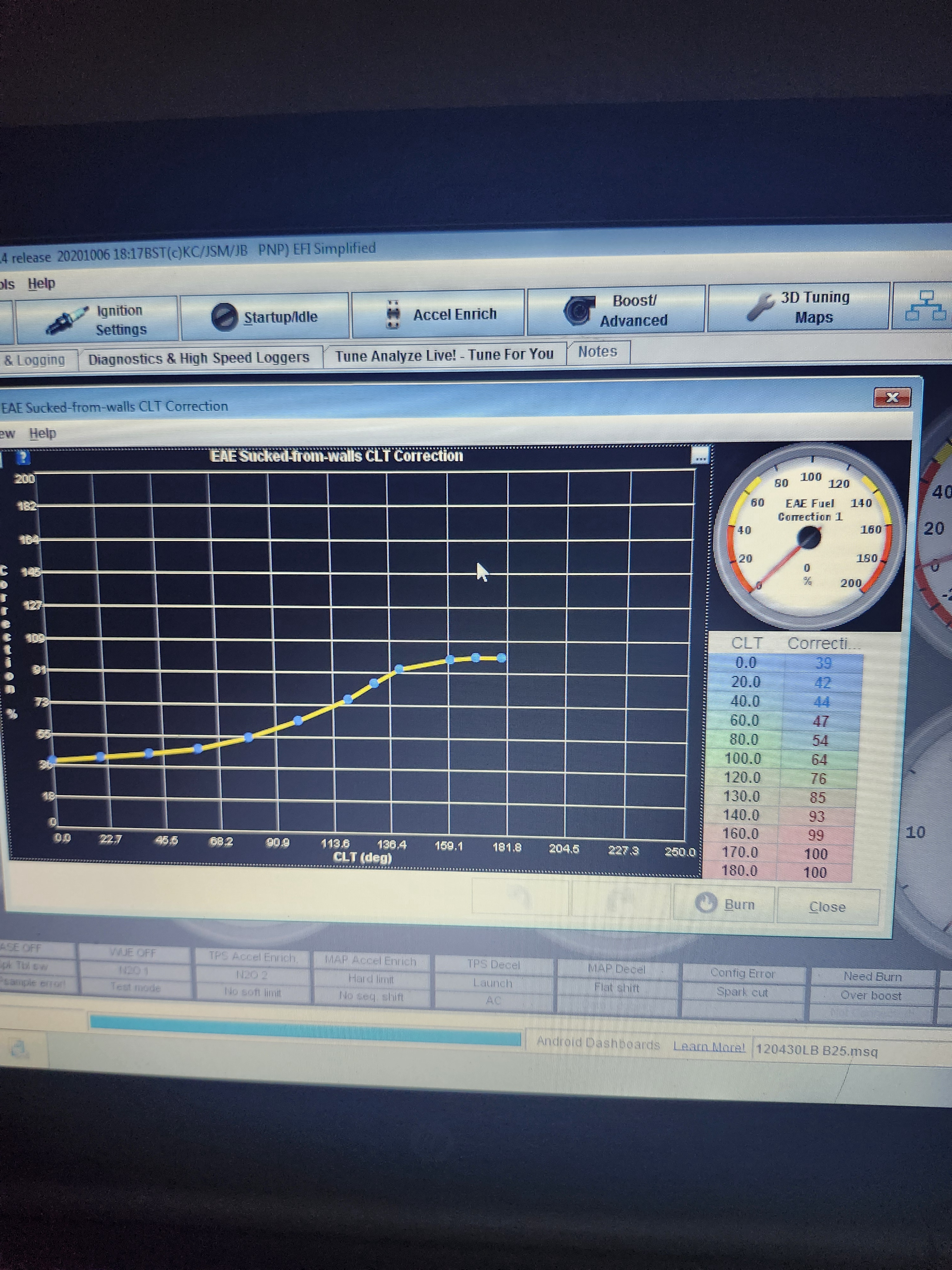

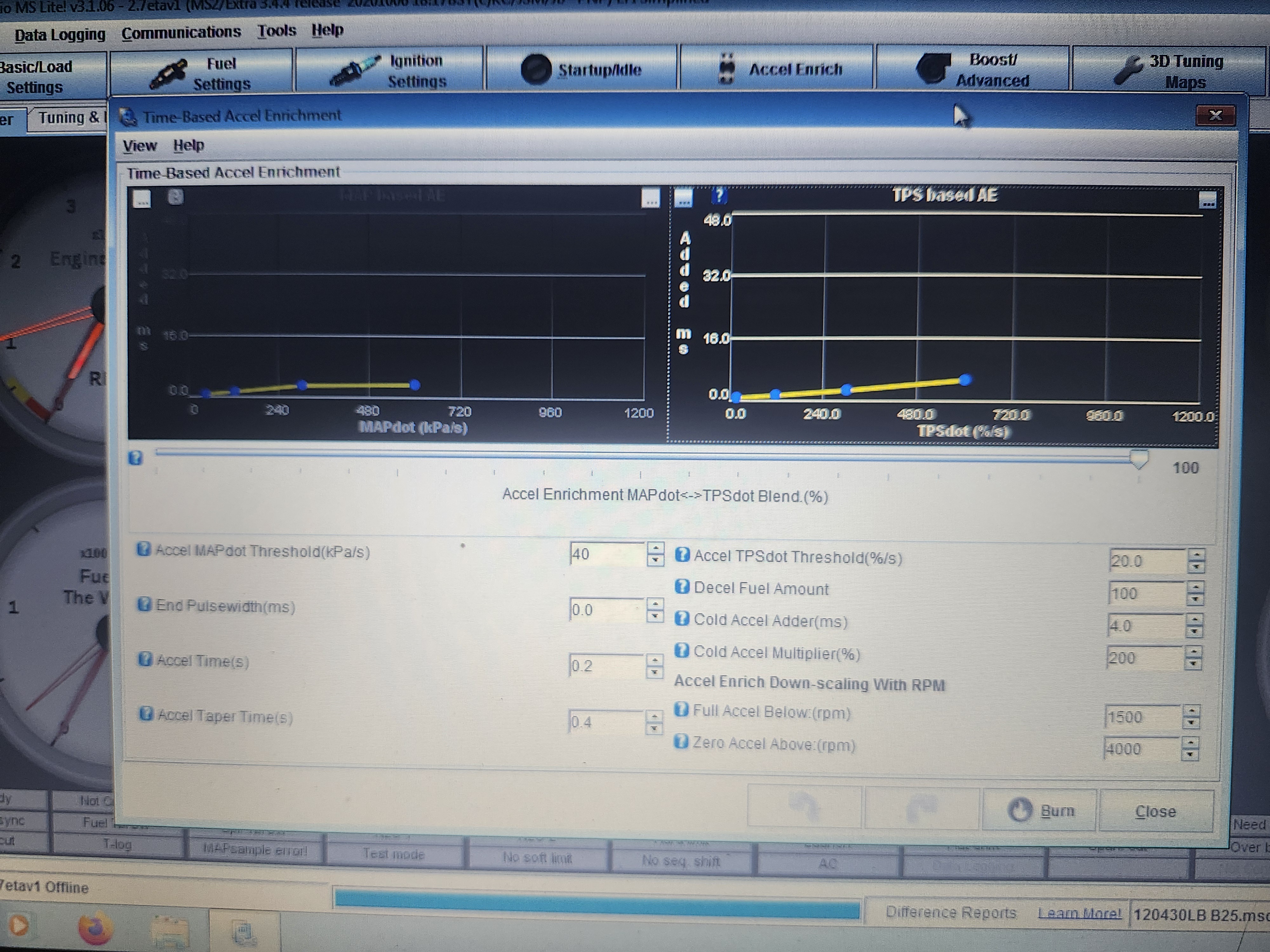

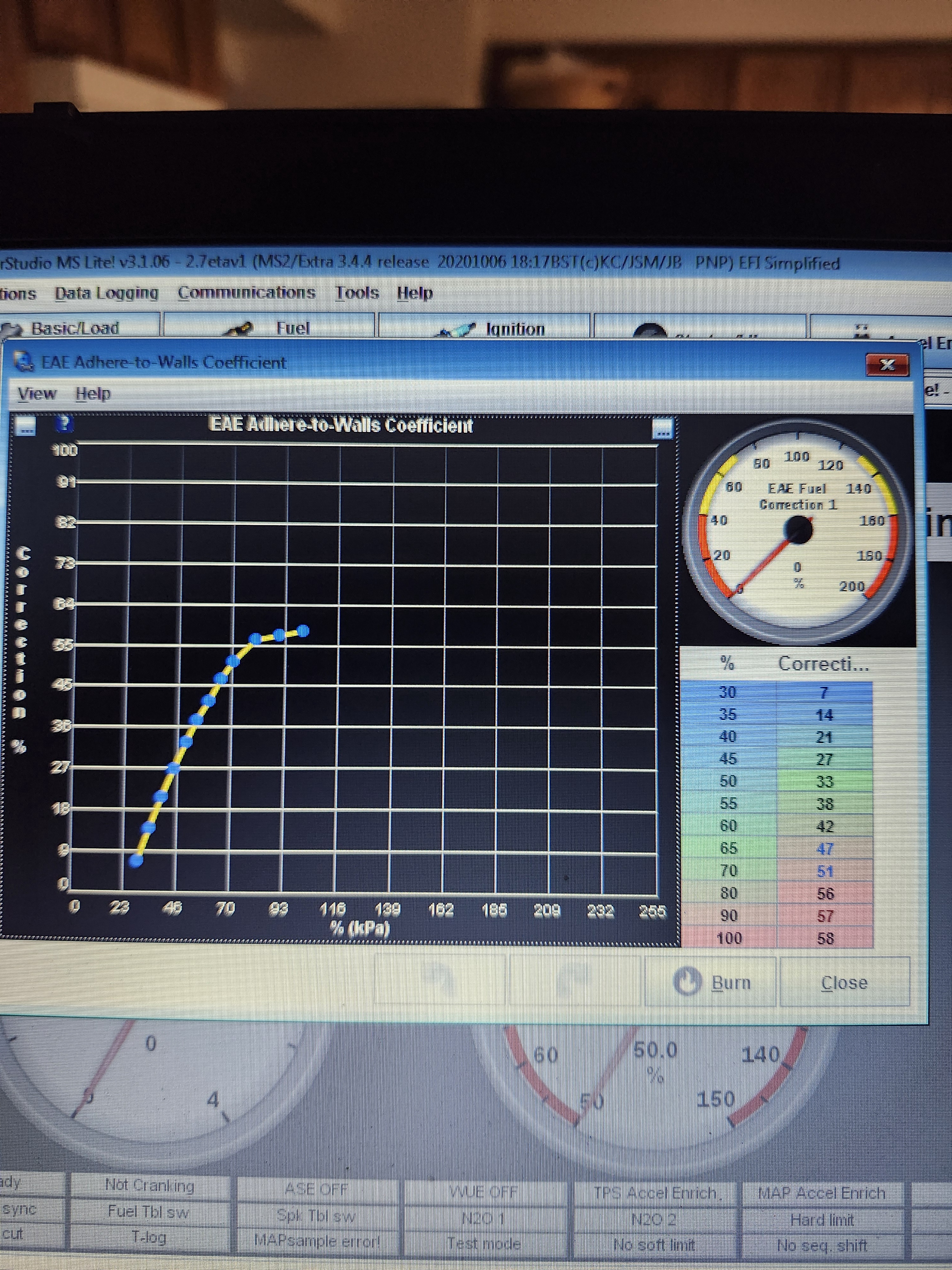

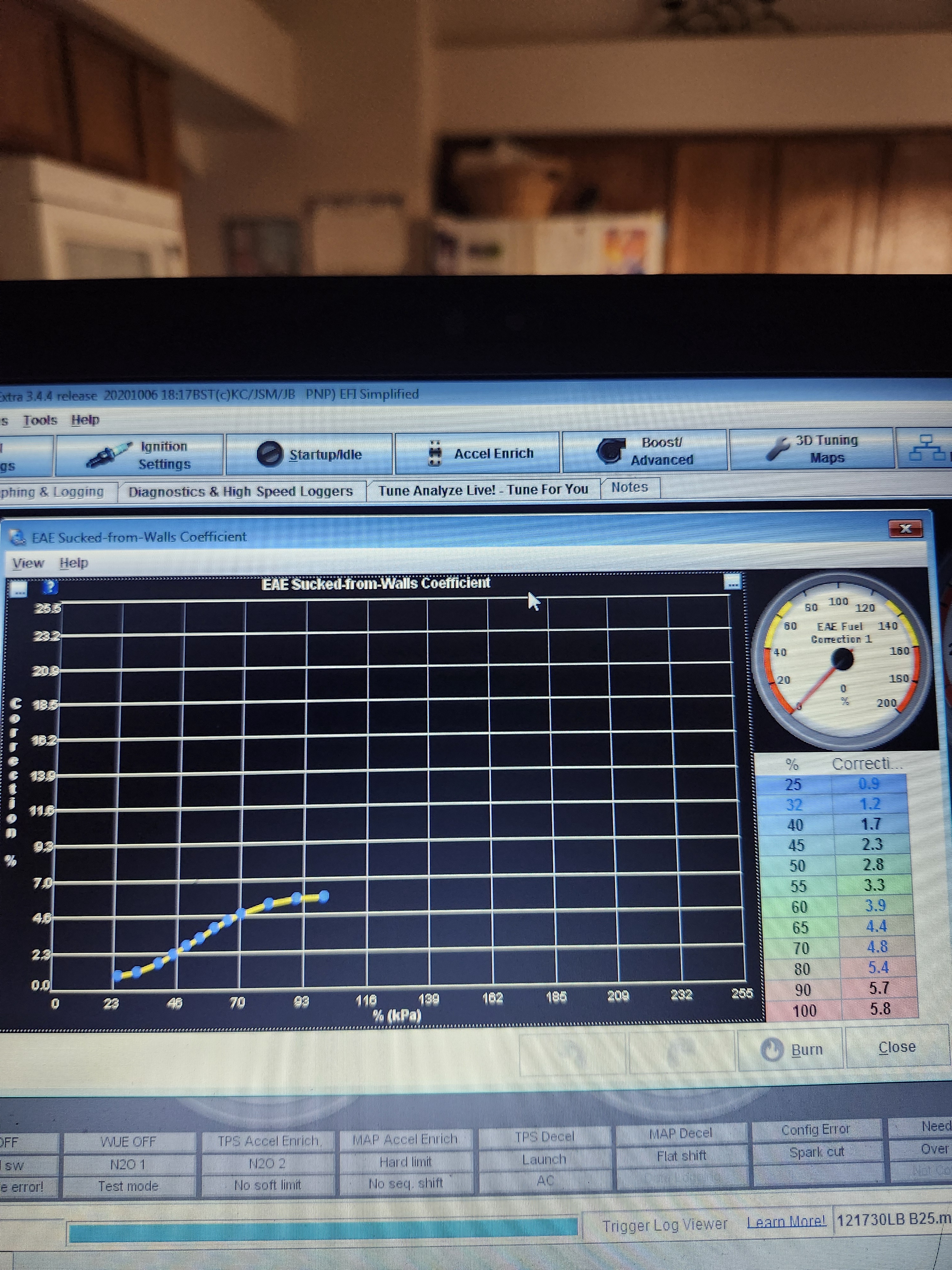

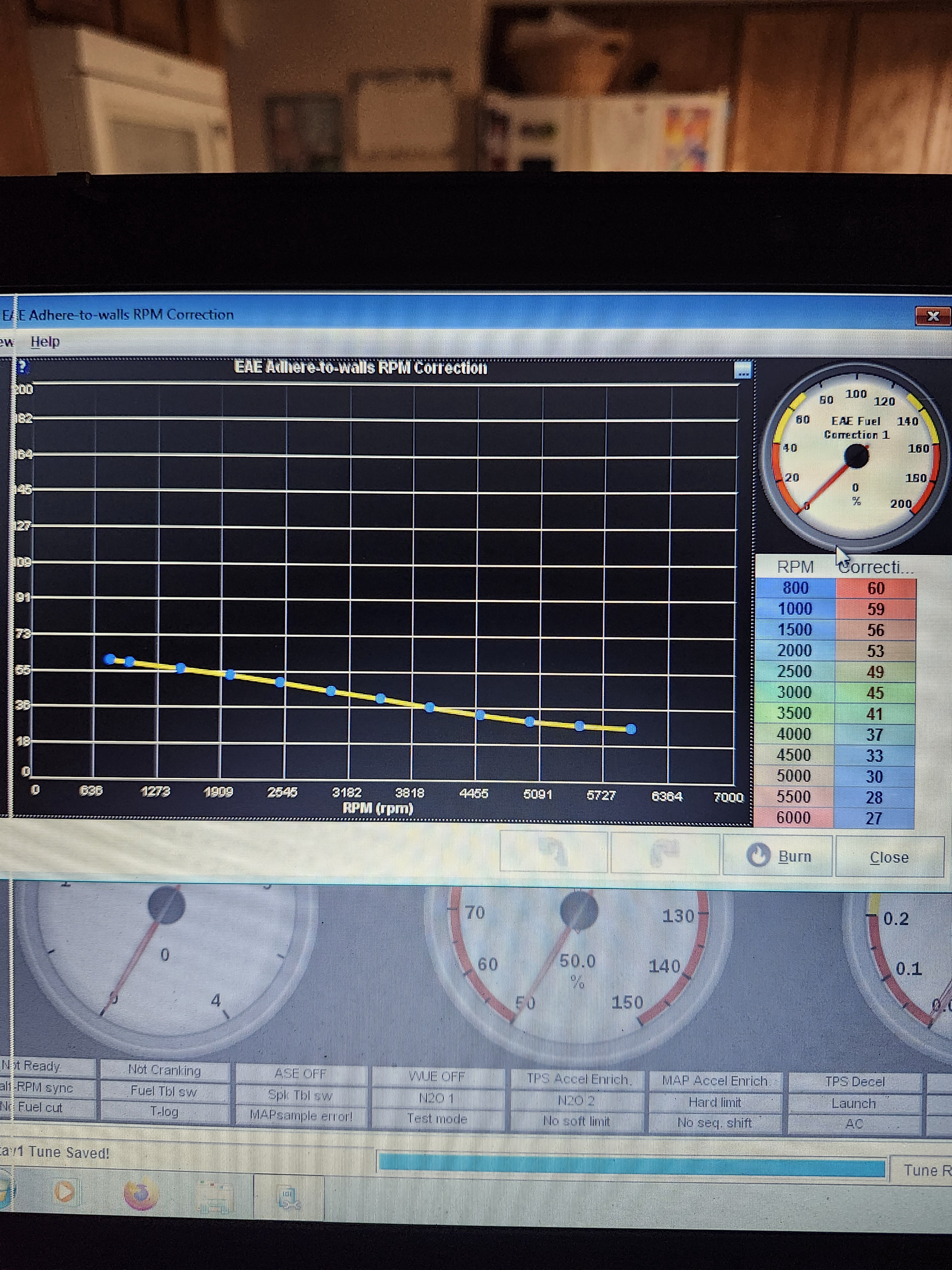

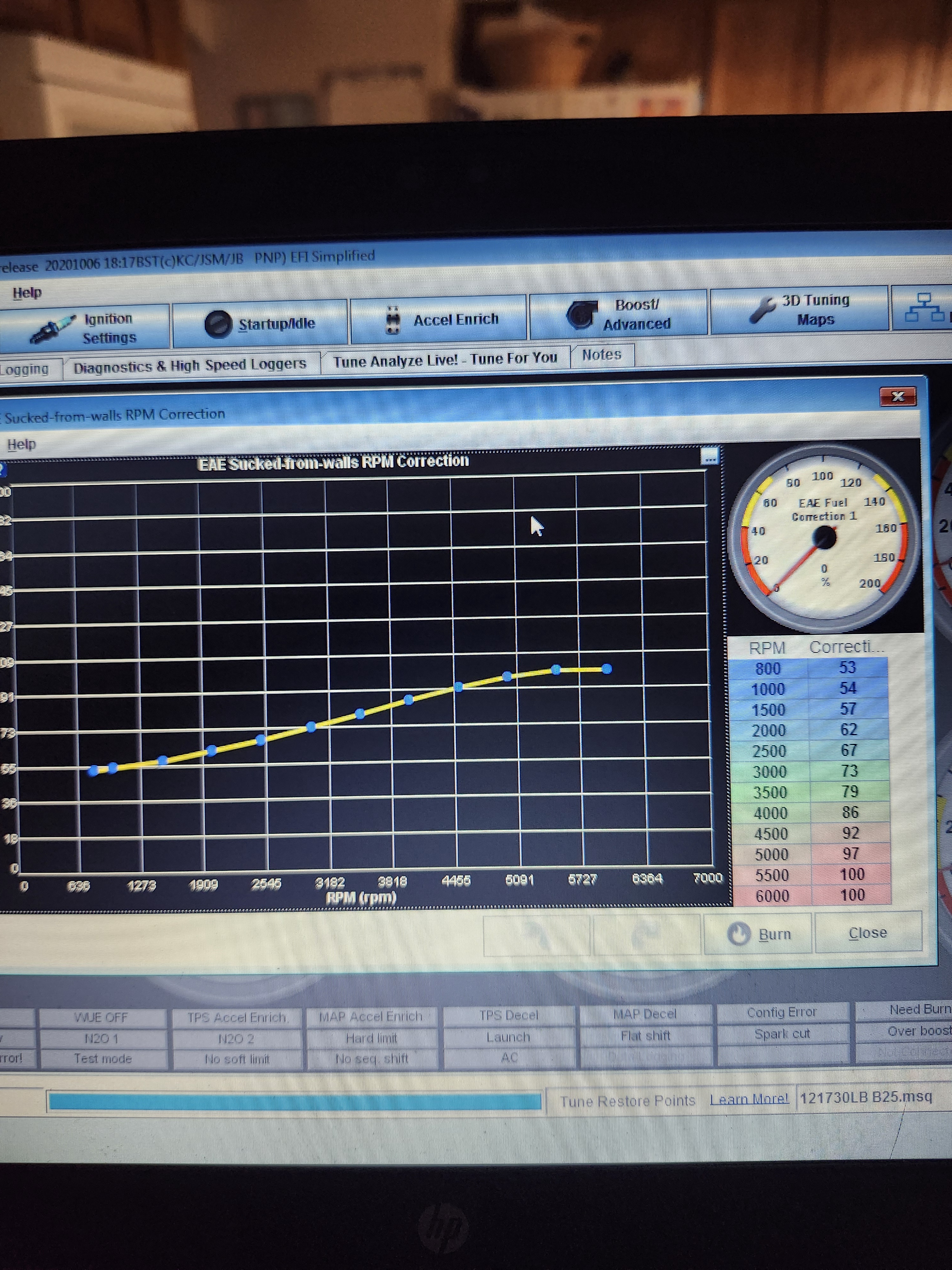

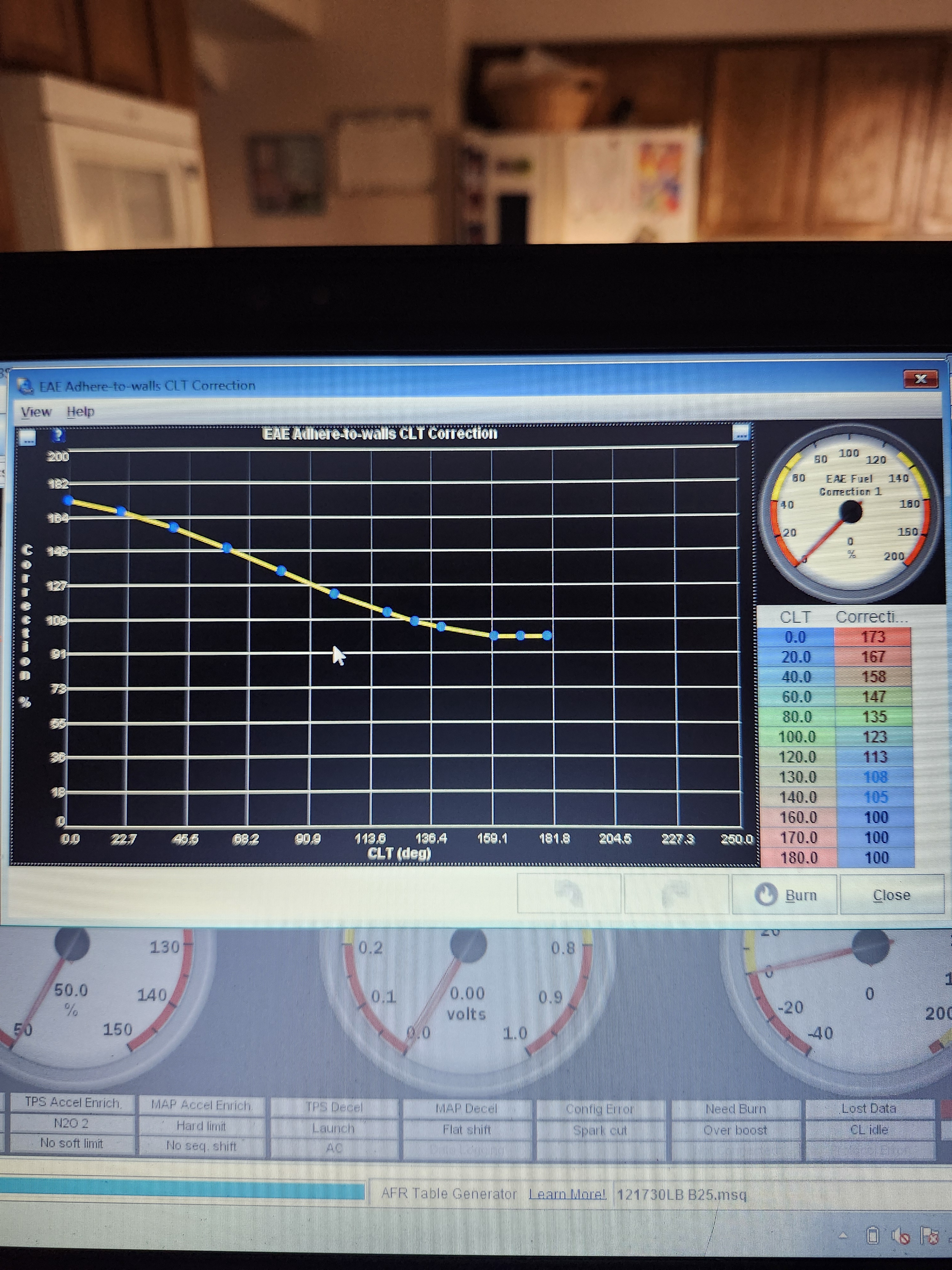

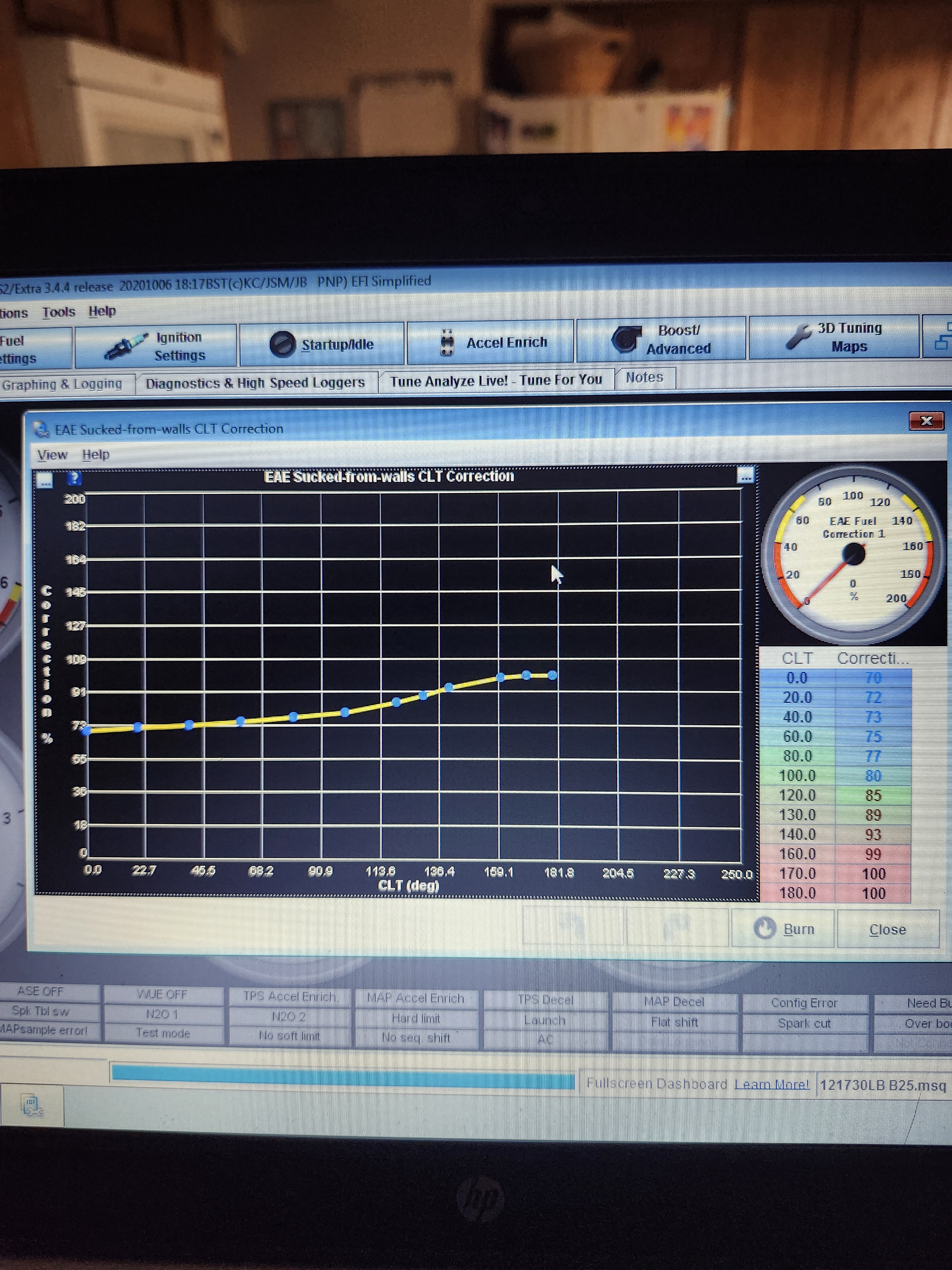

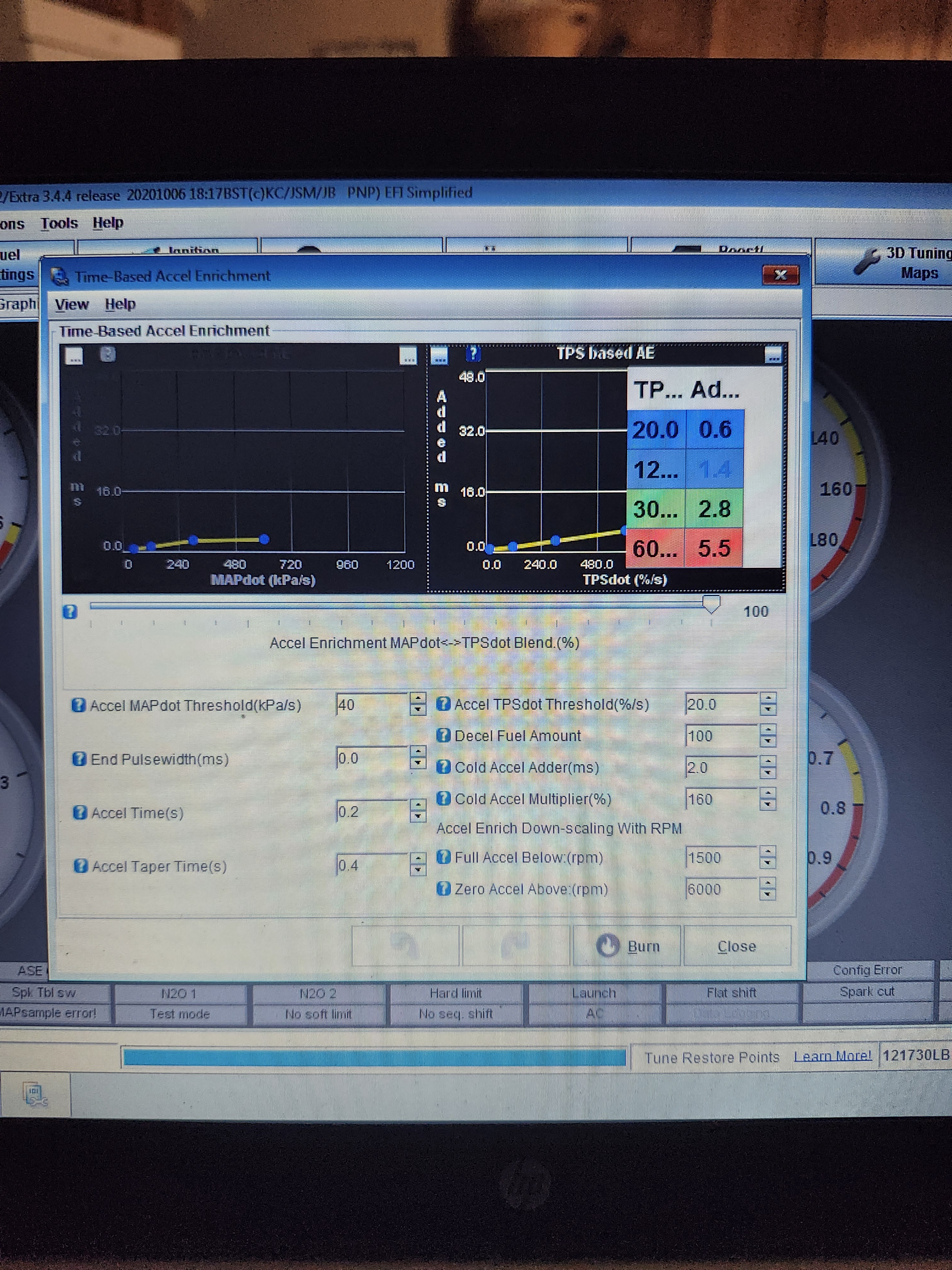

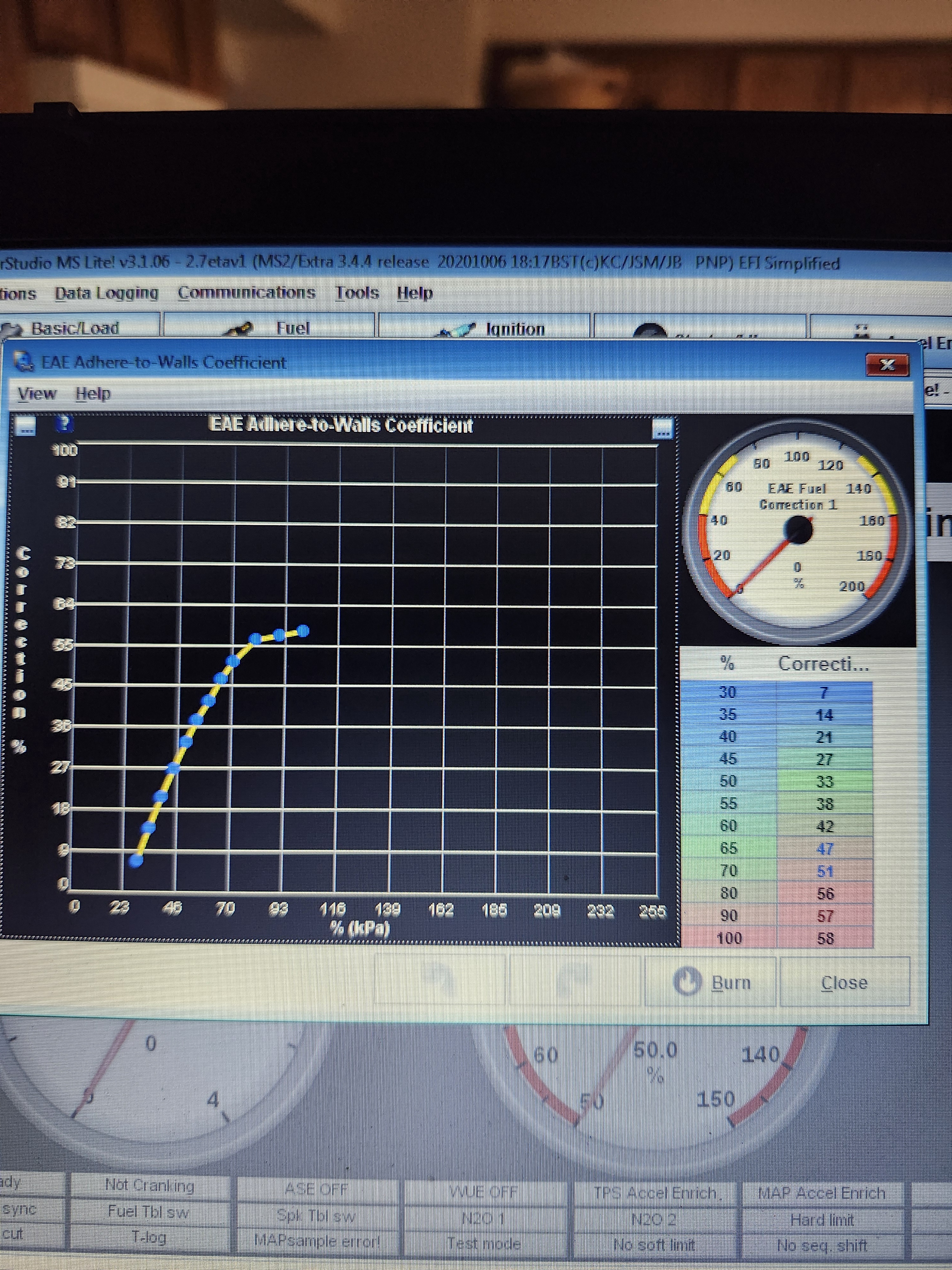

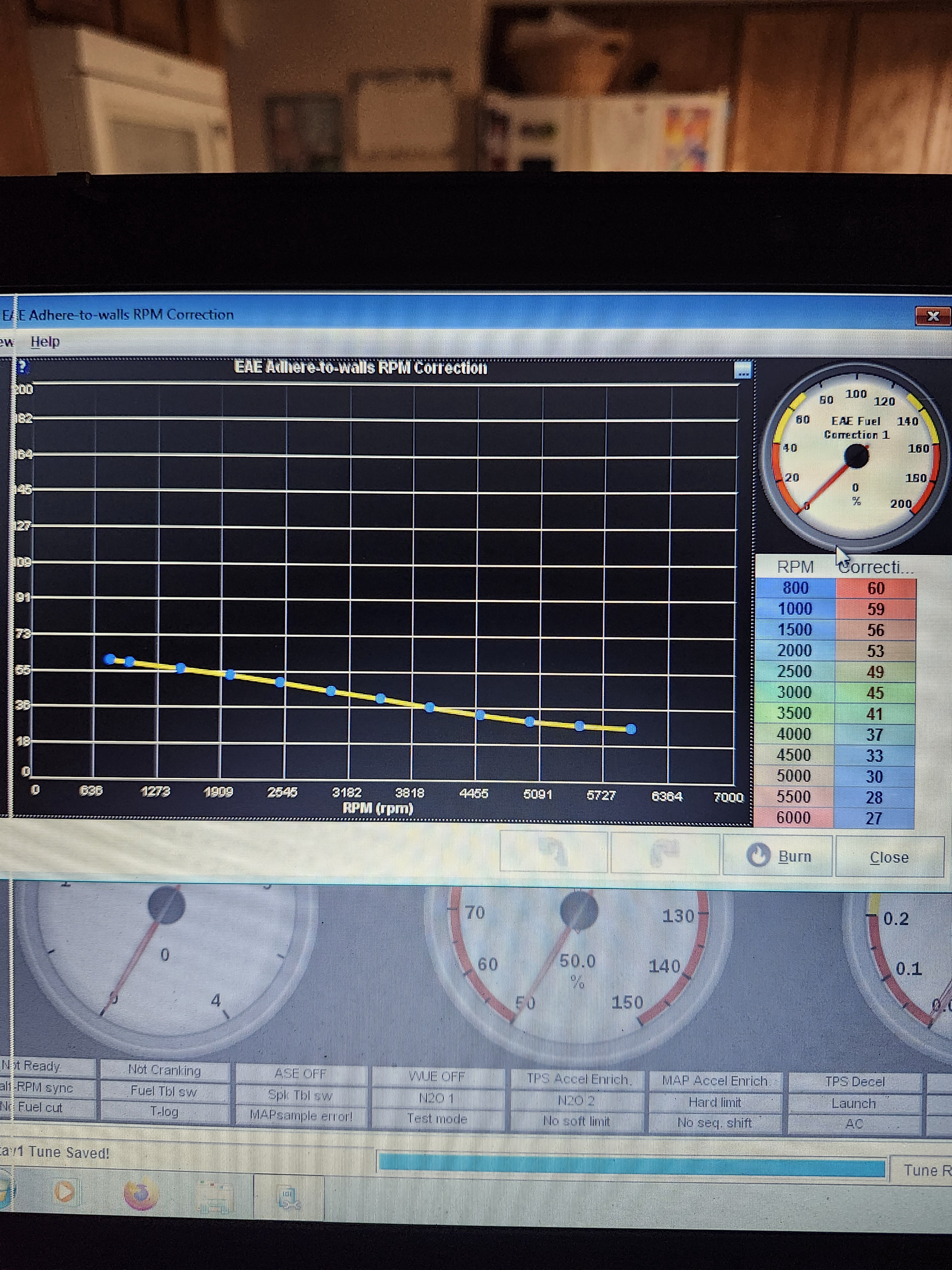

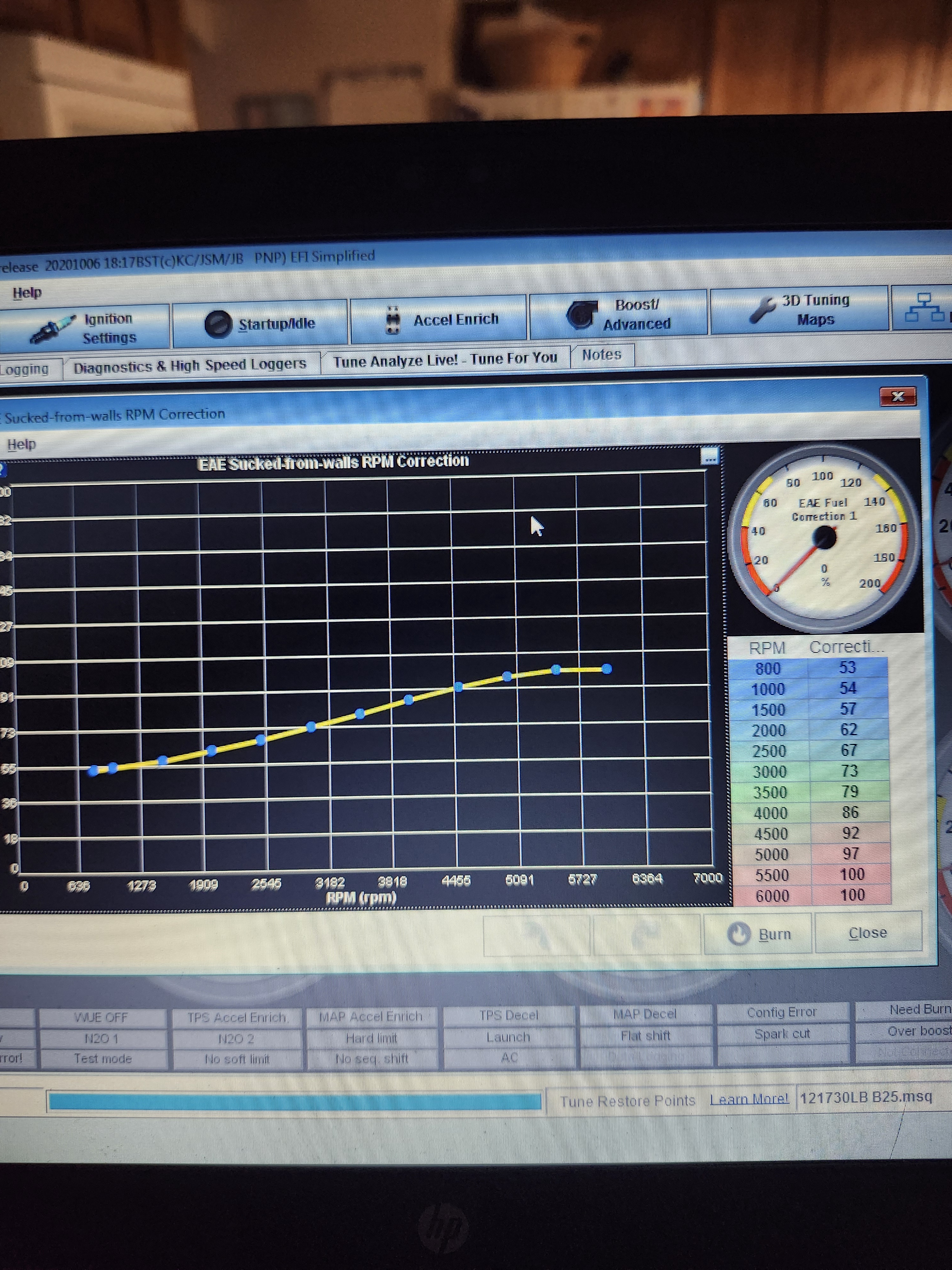

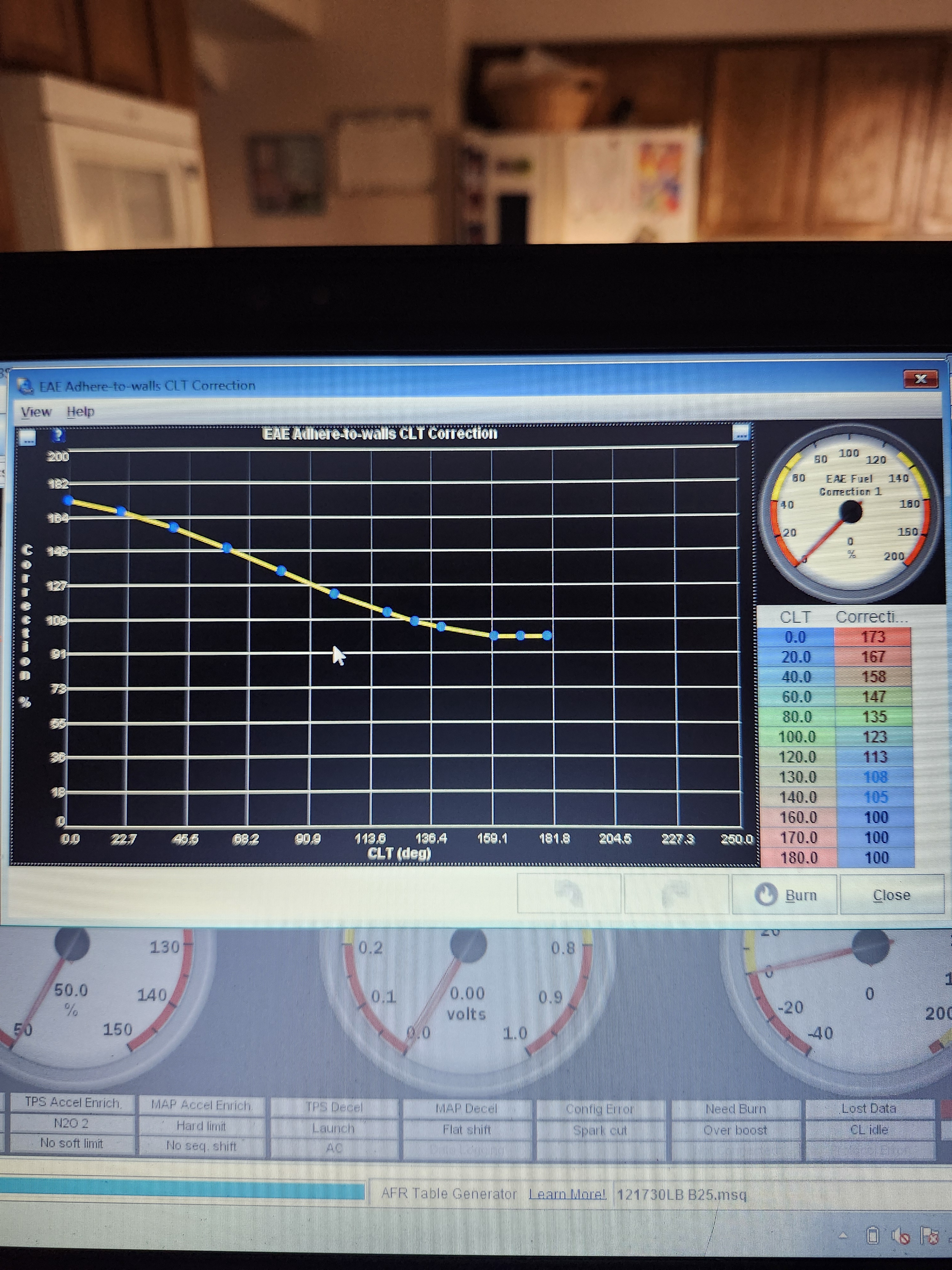

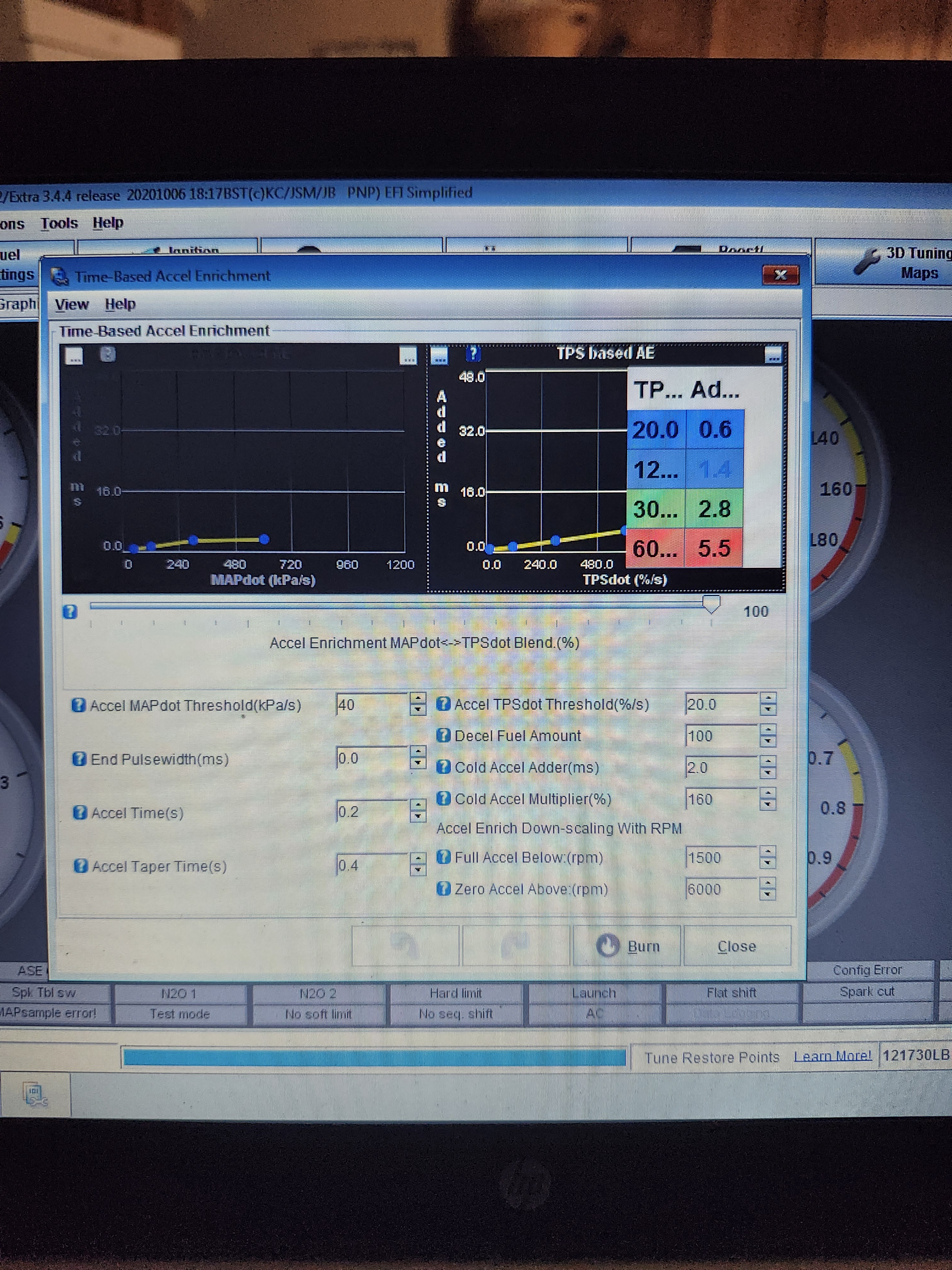

Never did get to the dyno, but I do have revised EAE settings. The previous settings worked well in conjunction with significant TPS based enrichment. When I take the TPS based AE out they don't work well at all, so I thought I would try to improve the performance of EAE on its own.

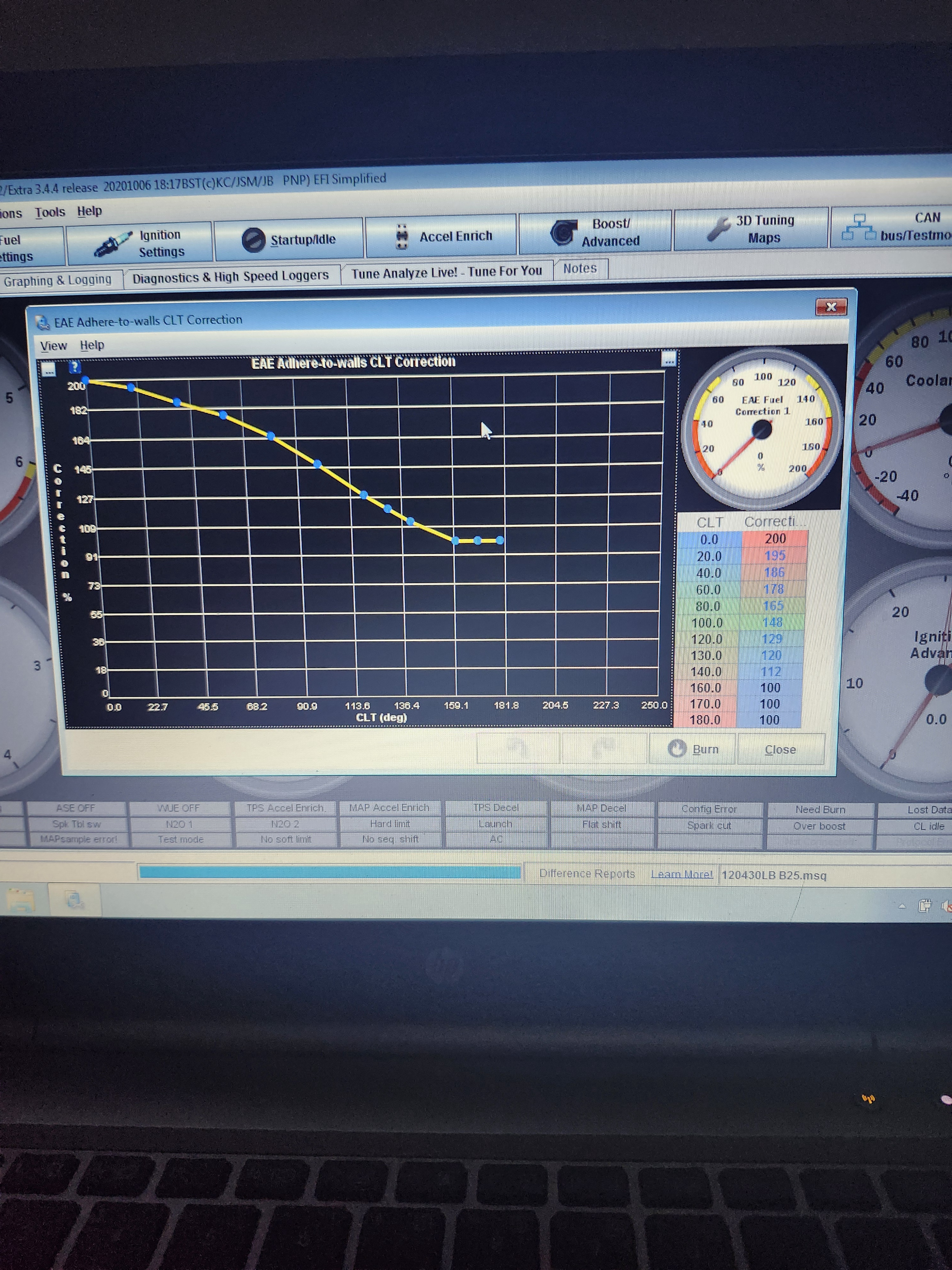

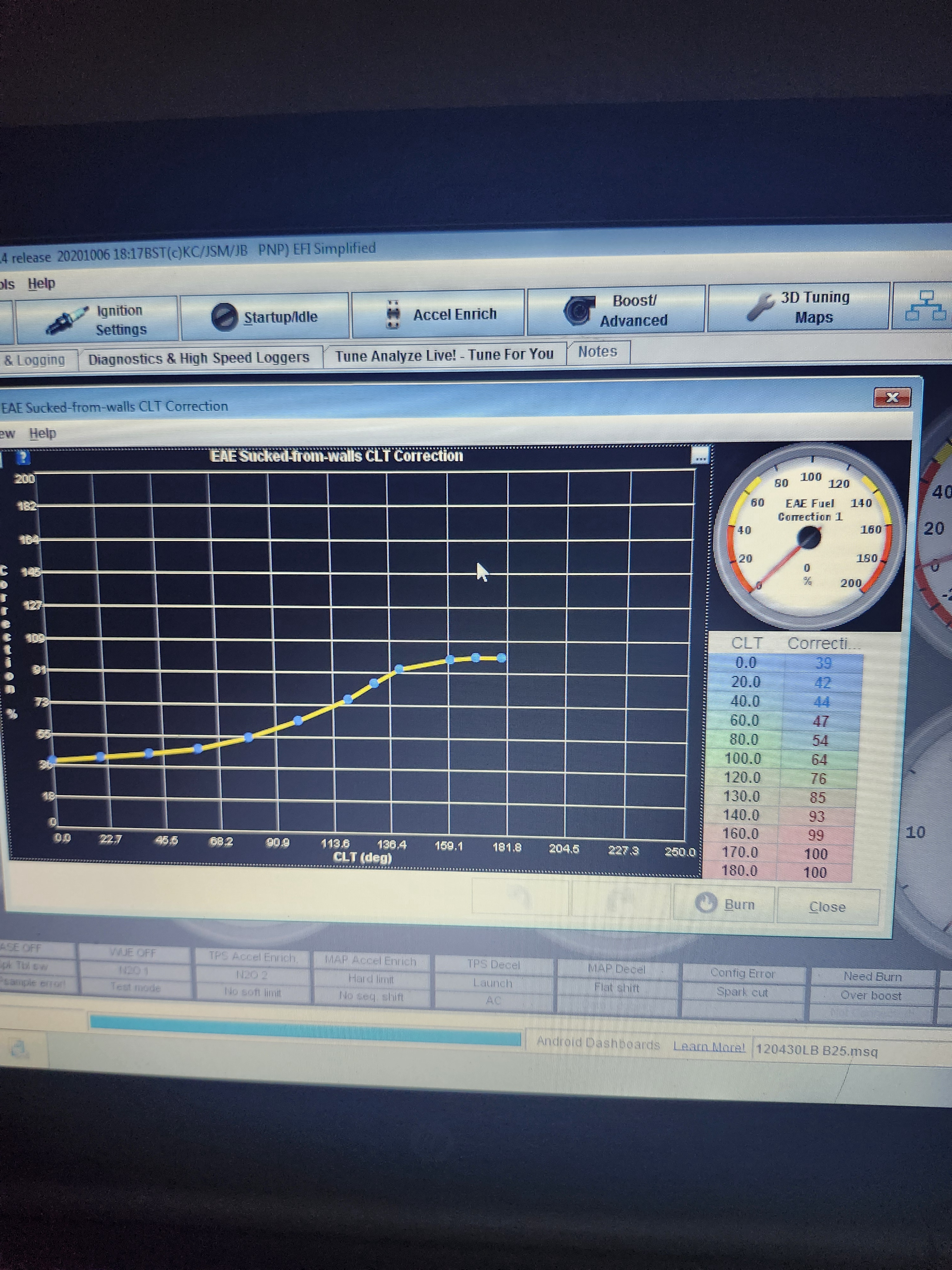

I believe there is an inherent flaw in the EAE code that causes a bit of an issue during warm up. The way I understand EAE, it is calculating a numerical value to represent the amount of fuel pooling in the intake port. It does not factor in what I would call "lost fuel", this is fuel that remains liquid and does not vaporize and combust. This fuel metered by EAE and counted as "fuel on the walls" has in fact been drawn from the port walls and gone through the engine, but EAE still sees it on the port walls.

This is a problem because EAE doesn't work unless you are adding or removing fuel from the wall fuel pool. To add in the required enrichment after a cold start as you drive away, EAE must see a bunch of fuel being added to the walls and it will kick in that much extra to maintain a stable AFR. Since EAE doesn't have a correction factor for "lost fuel", the wall fuel value bloats out of control when cold as EAE assumes a massive amount of fuel is accumulating on the walls. This results in inappropriate corrections in both directions, not enough on tip in and too much correction as you lift off of the throttle. As the engine warms, the fuel vaporizes more readily, the lost fuel factor becomes negligible and the algorithm works as it should. The trick has been finding coolant temp correction settings that make this work without being able to factor in the lost fuel, and I think these settings are about as good as it gets. Moderate throttle movements are recommended, just drive like the engine is cold which you should be doing anyway. When warm, it drives very well with much less TPS based AE than before. TPS AE is perfect for cold starts and low coolant temps, but I don't know if there's a way I can configure it so it provides the necessary boost when cold without providing excessive enrichment when the engine is warm and EAE is up and running.

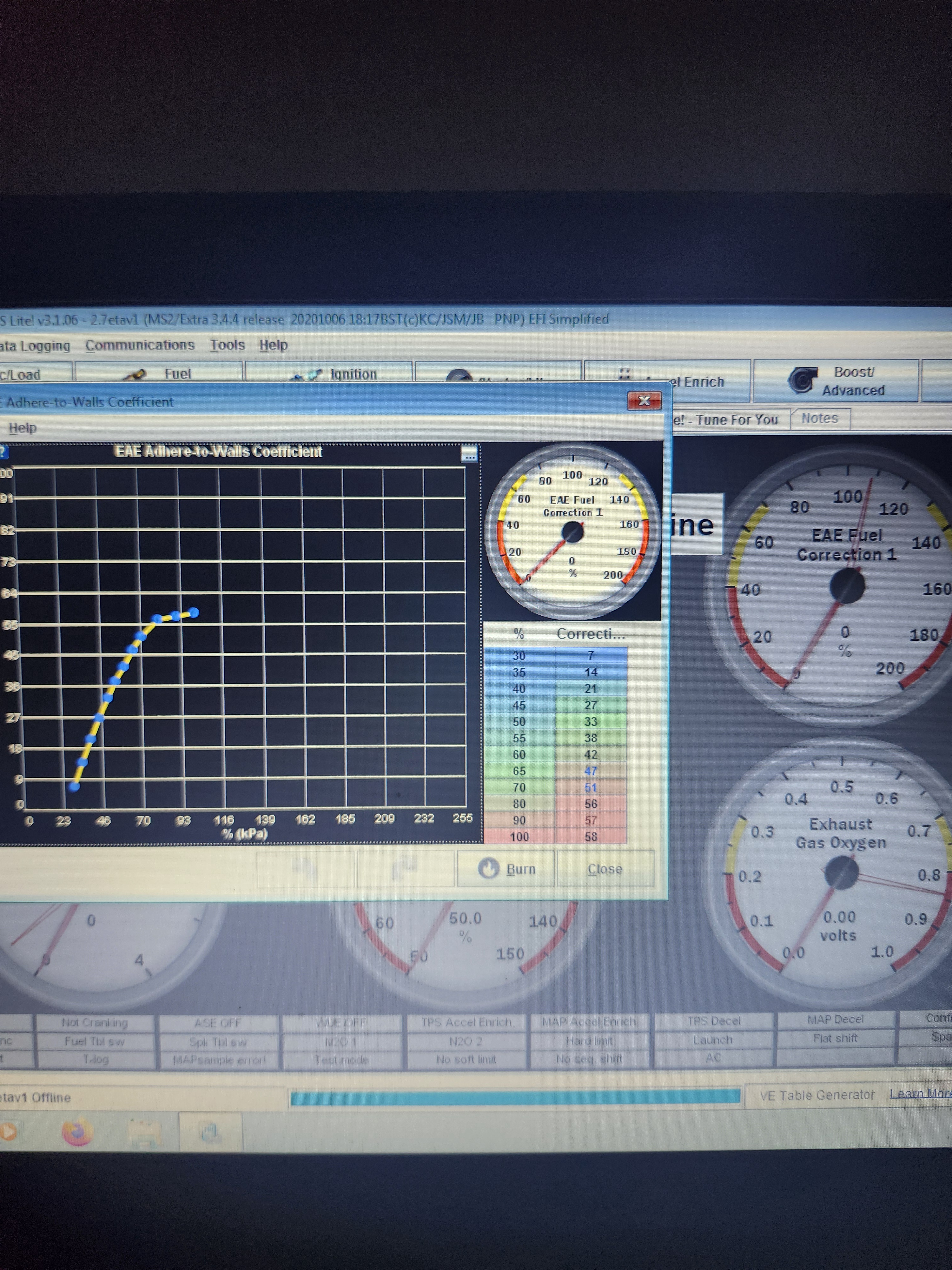

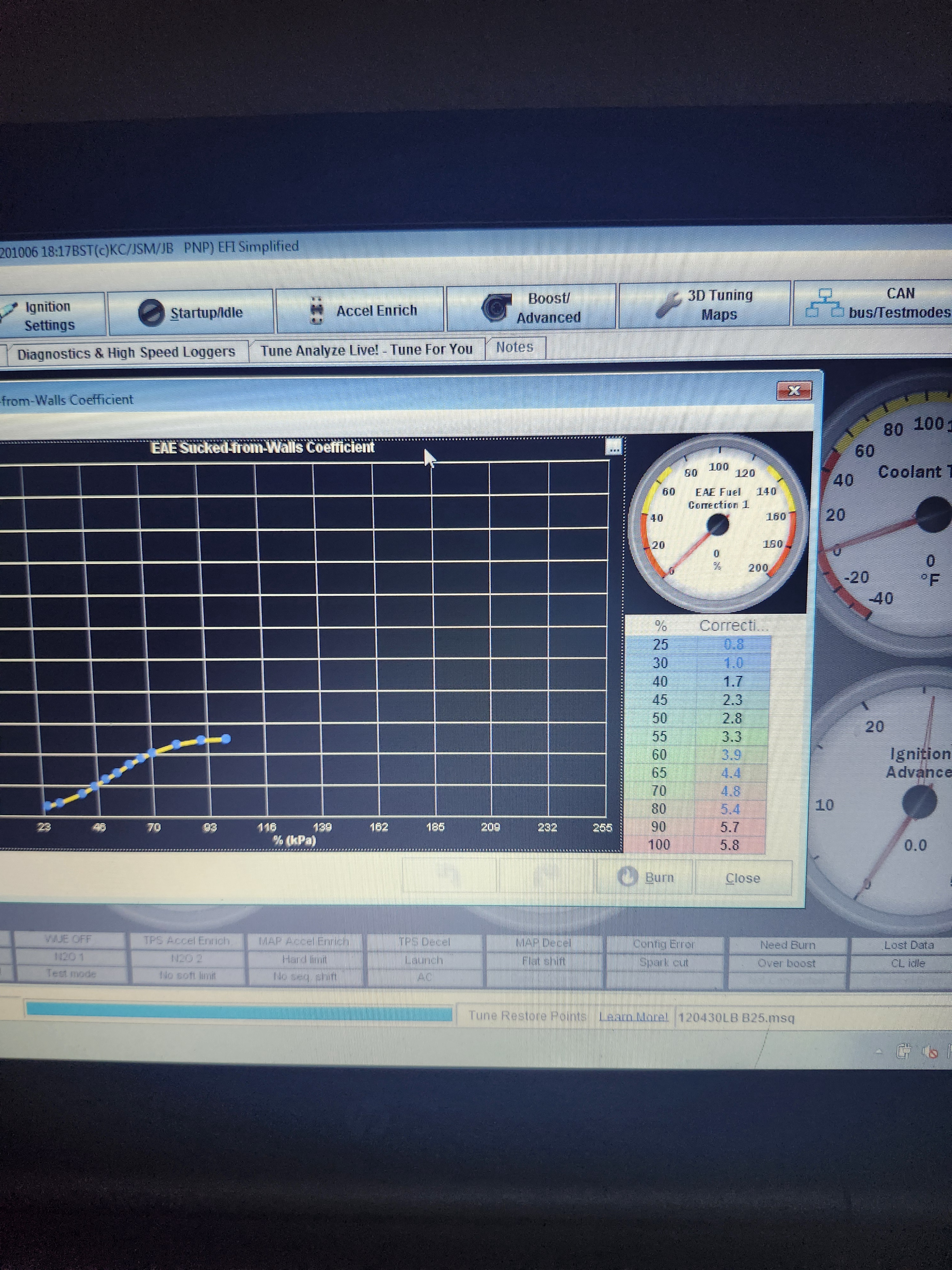

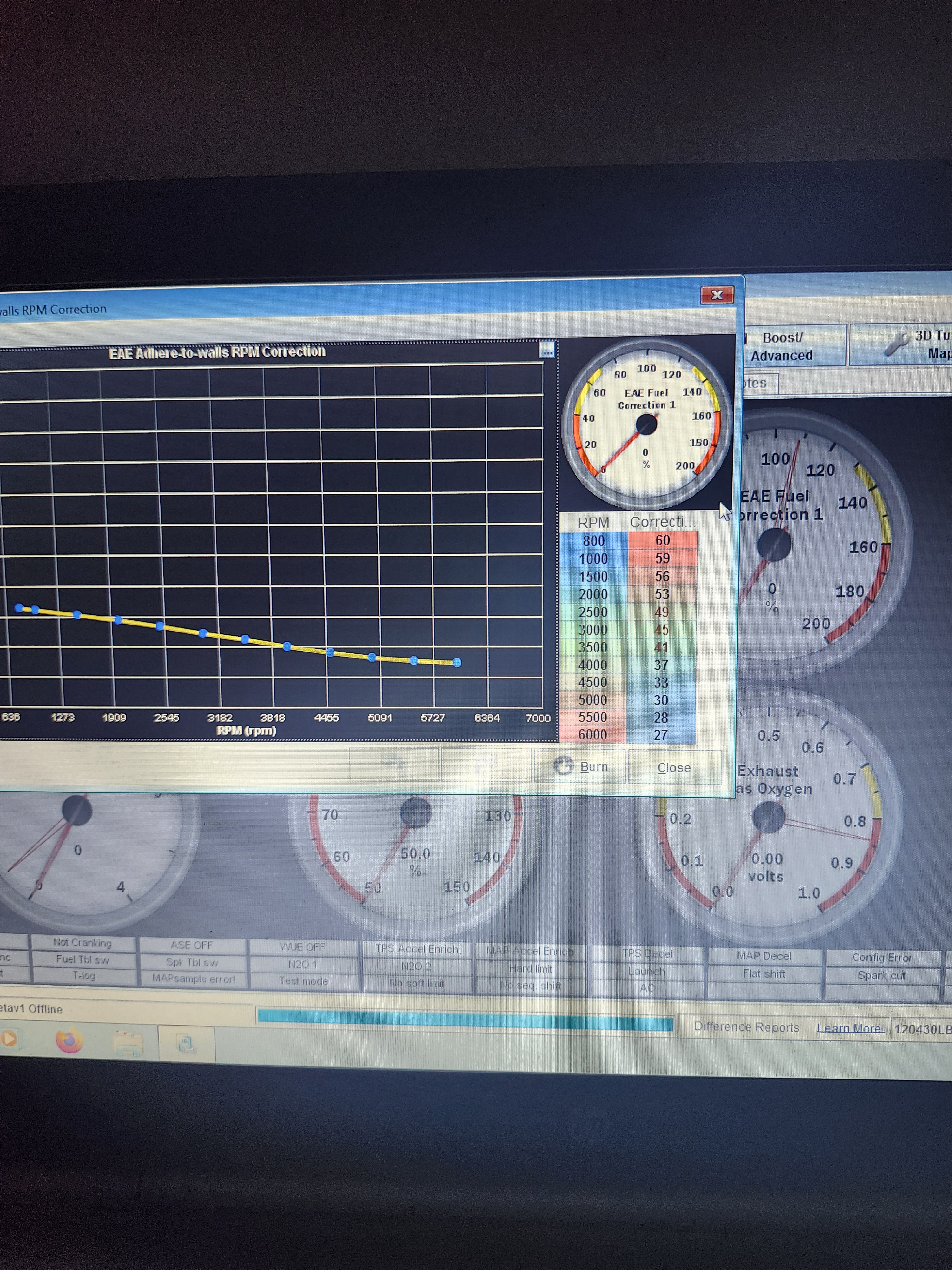

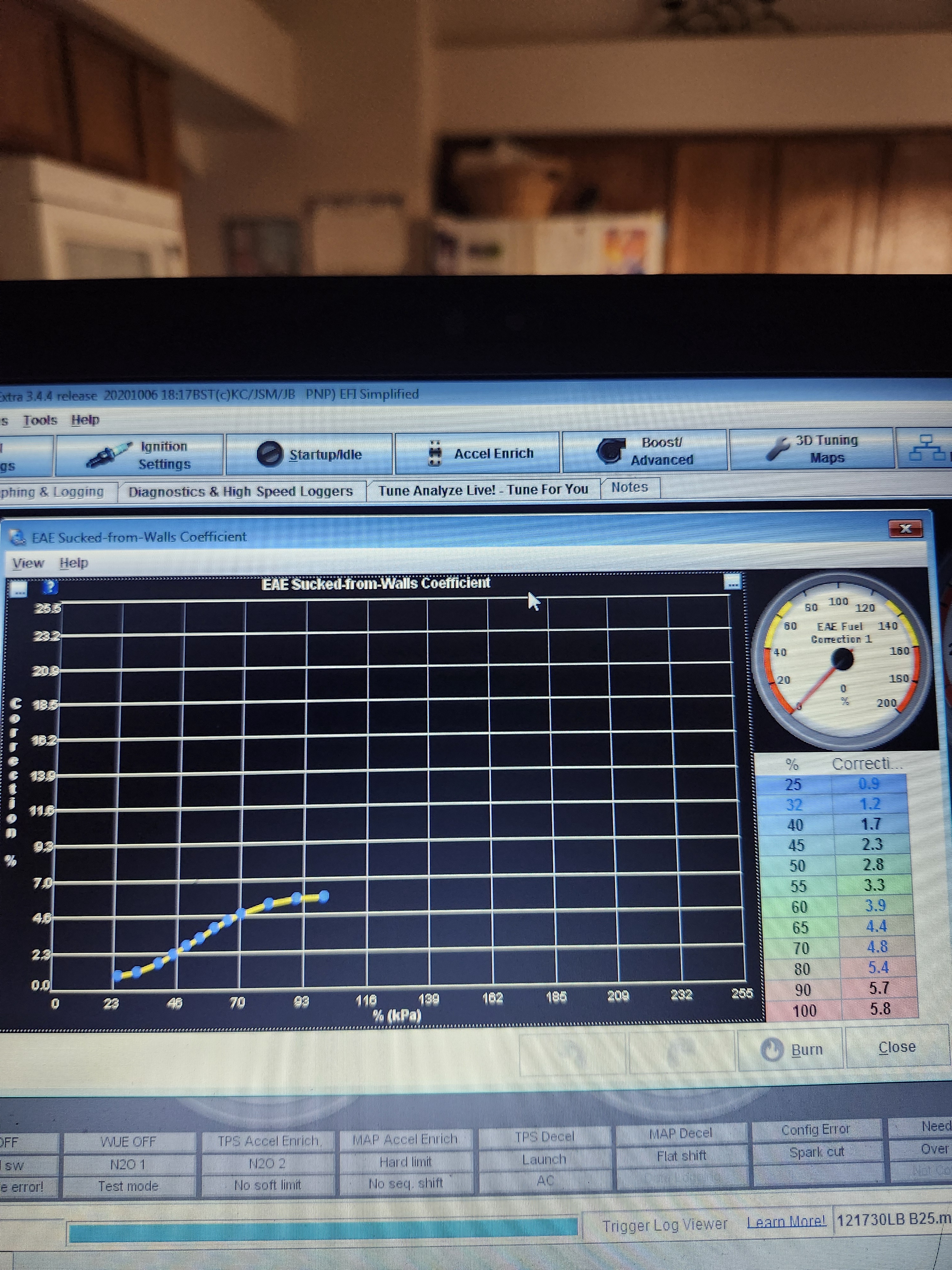

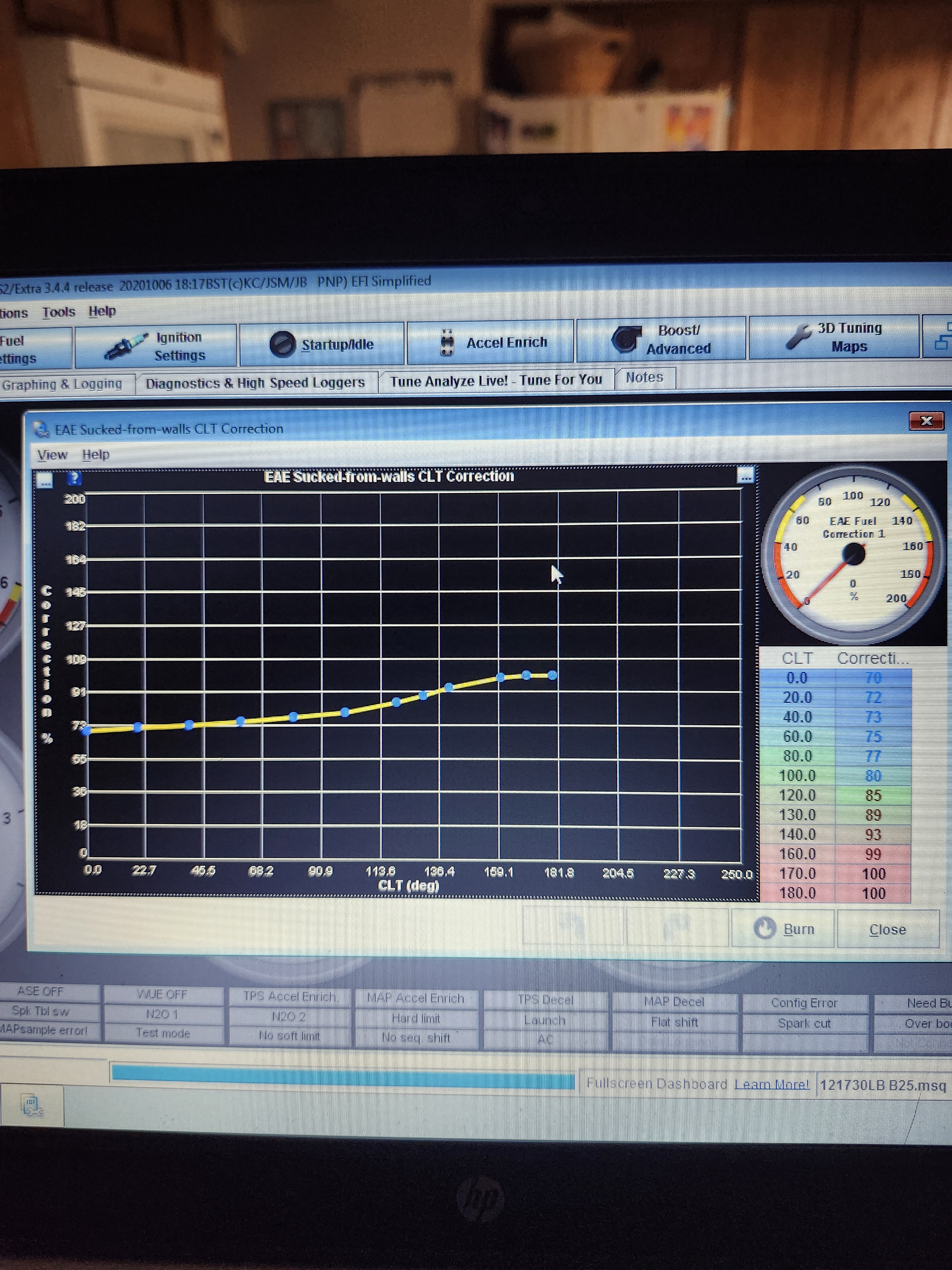

What a monster to tune though. You can never isolate a variable. Not enough enrichment on tip in is often caused by an insufficient "sucked from walls" setting. If it didn't take enough off of the walls during a gearshift, from the time you lifted off the throttle until you stepped back into it, it will think there's more fuel on the walls than there is and it will apply insufficient enrichment on the next tip in. Balancing added to and sucked from is crucial. Any time the wall fuel total starts to get unreasonably big, it's going to make unreasonable corrections. What constitutes close enough has to be nearly impeccable.

The biggest change in my strategy was to abandon any attempt to maintain a relationship between the "added to" and "sucked from" curves relative to each other. It helps to increase the "sucked from" coefficient at low kpa, you may notice that my curve now bends upward at low kpa. This helps with response on upshifts where it only has a brief period to pull fuel from the walls before it needs to add enrichment again. It should be pulling fuel from the walls, under a strong vacuum the fuel is encouraged to vaporize.

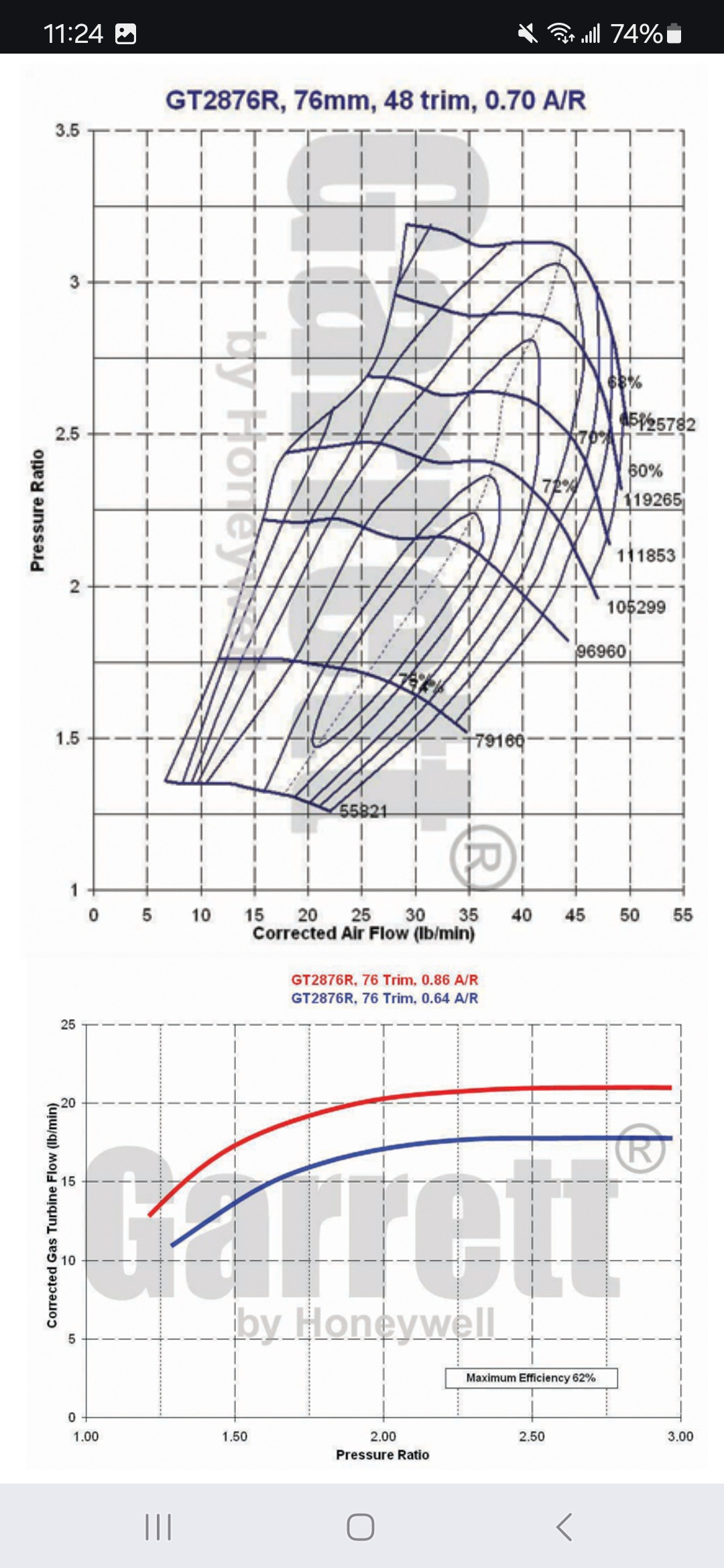

Other than all that, the car has been running great. No issues with the head gasket or clutch, despite having turned the boost up. It was hitting a little over 1 bar on spoolup, but this little turbine is having a hard time maintaining full boost past 5000 RPM. It dips to about .8 bar and holds that the rest of the way up. I am seriously considering a GT2860R or GT2860RS with a .86 AR turbine. Could go with another GT2871R .86. You can feel that boost tapering off and I hate it. Could be stomping a little bit more ass if it were maintaining full boost all the way up.

I believe there is an inherent flaw in the EAE code that causes a bit of an issue during warm up. The way I understand EAE, it is calculating a numerical value to represent the amount of fuel pooling in the intake port. It does not factor in what I would call "lost fuel", this is fuel that remains liquid and does not vaporize and combust. This fuel metered by EAE and counted as "fuel on the walls" has in fact been drawn from the port walls and gone through the engine, but EAE still sees it on the port walls.

This is a problem because EAE doesn't work unless you are adding or removing fuel from the wall fuel pool. To add in the required enrichment after a cold start as you drive away, EAE must see a bunch of fuel being added to the walls and it will kick in that much extra to maintain a stable AFR. Since EAE doesn't have a correction factor for "lost fuel", the wall fuel value bloats out of control when cold as EAE assumes a massive amount of fuel is accumulating on the walls. This results in inappropriate corrections in both directions, not enough on tip in and too much correction as you lift off of the throttle. As the engine warms, the fuel vaporizes more readily, the lost fuel factor becomes negligible and the algorithm works as it should. The trick has been finding coolant temp correction settings that make this work without being able to factor in the lost fuel, and I think these settings are about as good as it gets. Moderate throttle movements are recommended, just drive like the engine is cold which you should be doing anyway. When warm, it drives very well with much less TPS based AE than before. TPS AE is perfect for cold starts and low coolant temps, but I don't know if there's a way I can configure it so it provides the necessary boost when cold without providing excessive enrichment when the engine is warm and EAE is up and running.

What a monster to tune though. You can never isolate a variable. Not enough enrichment on tip in is often caused by an insufficient "sucked from walls" setting. If it didn't take enough off of the walls during a gearshift, from the time you lifted off the throttle until you stepped back into it, it will think there's more fuel on the walls than there is and it will apply insufficient enrichment on the next tip in. Balancing added to and sucked from is crucial. Any time the wall fuel total starts to get unreasonably big, it's going to make unreasonable corrections. What constitutes close enough has to be nearly impeccable.

The biggest change in my strategy was to abandon any attempt to maintain a relationship between the "added to" and "sucked from" curves relative to each other. It helps to increase the "sucked from" coefficient at low kpa, you may notice that my curve now bends upward at low kpa. This helps with response on upshifts where it only has a brief period to pull fuel from the walls before it needs to add enrichment again. It should be pulling fuel from the walls, under a strong vacuum the fuel is encouraged to vaporize.

Other than all that, the car has been running great. No issues with the head gasket or clutch, despite having turned the boost up. It was hitting a little over 1 bar on spoolup, but this little turbine is having a hard time maintaining full boost past 5000 RPM. It dips to about .8 bar and holds that the rest of the way up. I am seriously considering a GT2860R or GT2860RS with a .86 AR turbine. Could go with another GT2871R .86. You can feel that boost tapering off and I hate it. Could be stomping a little bit more ass if it were maintaining full boost all the way up.

Re: Turbo ETA build

Thanks for sharing, I will try these settings.

None of my acceleration enrichments have worked well enough for me. I'll give this a try this weekend or early next week and maybe see what it looks like on the datalog as well.

I always seem to have rich on tip wn, though I hD it dialed in ok previously with tps only enrichment. But it's always a bit rich in throttle lift, and has never felt like what I would call snappy for throttle response. Could be related to my intake and intercooler piping length maybe...

None of my acceleration enrichments have worked well enough for me. I'll give this a try this weekend or early next week and maybe see what it looks like on the datalog as well.

I always seem to have rich on tip wn, though I hD it dialed in ok previously with tps only enrichment. But it's always a bit rich in throttle lift, and has never felt like what I would call snappy for throttle response. Could be related to my intake and intercooler piping length maybe...

Re: Turbo ETA build

That's what I really like about EAE, it corrects the mixture continuously to maintain a stable AFR. Adds a percentage on throttle application and pulls some back as you lift off. It has the potential to save quite a bit of fuel, and when it works well it makes a remarkable difference. If you're running 13:1 across the map, a 10% deviation from stoich is no big deal. At 14.7:1 it is a huge problem, but EAE makes it possible. TPS based AE will never work well for slow throttle movements. A whole lot happens below a rate of 20%/sec during normal driving, but at least for me the noise in the TPS signal makes it unsuitable below that rate.

Those settings are working well from about 100-120 degrees on up to operating temperature. At operating temp, they are fantastic. Below 100, I think there is still more work to be done. Yesterday I took a bit of fuel out of the added to walls coolant temp correction curve and cut back the added PW and percentage for cold TPS based enrichment, which was a step in the right direction. I would rather be a little lean than rich enough to misfire, though either option is irritating. There is an ideal balance of WUE and acceleration enrichments and I intend to continue dicking with it until I'm confident that it's as good as it gets. No matter what, it seems that I end up rich at low kpa and lean at high kpa. This may be attributable to the characteristics of the fuel. It vaporizes more readily under vacuum at cold temps, but once the throttle is opened it requires additional enrichment. When the engine is hot, it vaporizes more consistently at all manifold pressures. I would love to find a pressure temperature chart for gasoline, that would be very interesting. The freezing point is about 100 below zero, and it boils at around 150 degrees, but we would need to see a PTC to understand the effect that manifold vacuum has on the phase of the fuel. On a cold start, with the cylinder head at 19 degrees, the fuel certainly behaves differently.

As it sits right now, I added in some extra WUE and pulled back the acceleration enrichment coolant correction factors. The basic EAE coefficients and RPM correction factors are still good, once the temp gauge is into the blue it's starting to run well. I have the EGO control coming on around 75 degrees if I remember correctly, and I've allowed it 8% authority. This may be the way to go, set it up rich enough to drive smoothly and let the O2 sensor handle the rest.

The original turbo car was tuned to run open loop, probably around 13:1 most of the time. It was so much easier only using TPS AE, not giving a shit if it was rich when I lifted off the throttle. Probably stunk to drive behind that thing, running rich with no cat. That won't do this time around.

Those settings are working well from about 100-120 degrees on up to operating temperature. At operating temp, they are fantastic. Below 100, I think there is still more work to be done. Yesterday I took a bit of fuel out of the added to walls coolant temp correction curve and cut back the added PW and percentage for cold TPS based enrichment, which was a step in the right direction. I would rather be a little lean than rich enough to misfire, though either option is irritating. There is an ideal balance of WUE and acceleration enrichments and I intend to continue dicking with it until I'm confident that it's as good as it gets. No matter what, it seems that I end up rich at low kpa and lean at high kpa. This may be attributable to the characteristics of the fuel. It vaporizes more readily under vacuum at cold temps, but once the throttle is opened it requires additional enrichment. When the engine is hot, it vaporizes more consistently at all manifold pressures. I would love to find a pressure temperature chart for gasoline, that would be very interesting. The freezing point is about 100 below zero, and it boils at around 150 degrees, but we would need to see a PTC to understand the effect that manifold vacuum has on the phase of the fuel. On a cold start, with the cylinder head at 19 degrees, the fuel certainly behaves differently.

As it sits right now, I added in some extra WUE and pulled back the acceleration enrichment coolant correction factors. The basic EAE coefficients and RPM correction factors are still good, once the temp gauge is into the blue it's starting to run well. I have the EGO control coming on around 75 degrees if I remember correctly, and I've allowed it 8% authority. This may be the way to go, set it up rich enough to drive smoothly and let the O2 sensor handle the rest.

The original turbo car was tuned to run open loop, probably around 13:1 most of the time. It was so much easier only using TPS AE, not giving a shit if it was rich when I lifted off the throttle. Probably stunk to drive behind that thing, running rich with no cat. That won't do this time around.

Re: Turbo ETA build

Slight EAE tweaks:

Better still during warm up. I also moved one of the low kpa bins on the SFW coefficient and increased the low end of that curve a little more. Overall it's working great without a whole lot of TPS AE.

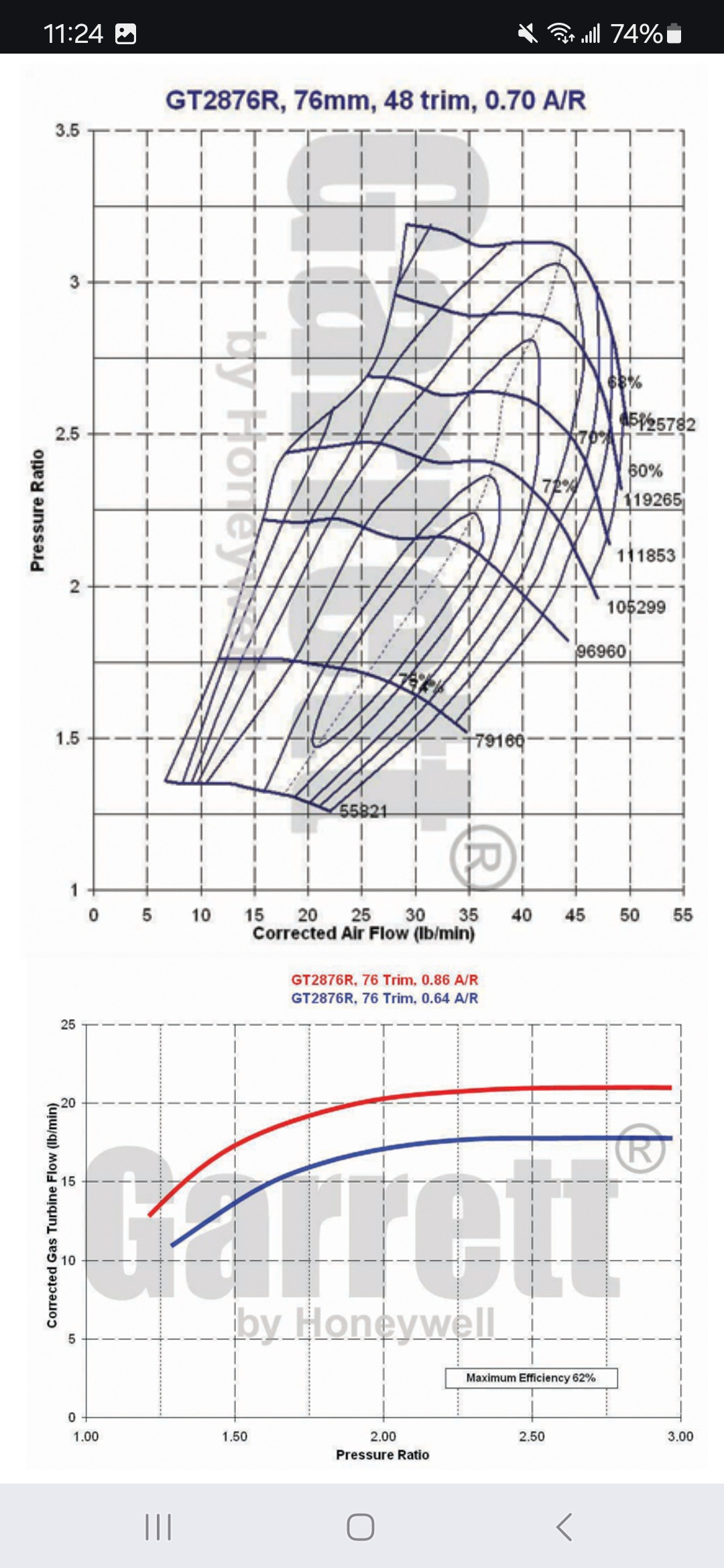

I ordered a new turbo too. Got tired of trying not to buy a new turbo, this was the only solution. The price seems too good but it does appear to be a genuine Garrett. We'll see what it gets here. Seller appears to be legit and it is discontinued by Garrett, they might just be trying to get rid of them.

This is the .86 AR variety. I believe that was the same turbine wheel and housing I was running with the GT2871R back in 2007 or 2008. It worked very well, not too sleepy but it had enough capacity to avoid choking up on the top end.

I figure it's about time to put spark plugs in this thing. This set has a few miles on them. I'll be taking the turbo off for that and a valve clearance check and I didn't really want to put the little GT2560R back on. It's been great but its not efficient beyond about 11 psi. Since the stock clutch and fuel pump seem to be capable of at least 1 bar, I'll be running 1 bar. Looking at the compressor map, this thing is capable of making 450+ rear wheel. I would want to go for a larger and more efficient turbine if I was going to push it that hard, though running in the 300ish horsepower range will be no trouble at all.

Better still during warm up. I also moved one of the low kpa bins on the SFW coefficient and increased the low end of that curve a little more. Overall it's working great without a whole lot of TPS AE.

I ordered a new turbo too. Got tired of trying not to buy a new turbo, this was the only solution. The price seems too good but it does appear to be a genuine Garrett. We'll see what it gets here. Seller appears to be legit and it is discontinued by Garrett, they might just be trying to get rid of them.

This is the .86 AR variety. I believe that was the same turbine wheel and housing I was running with the GT2871R back in 2007 or 2008. It worked very well, not too sleepy but it had enough capacity to avoid choking up on the top end.

I figure it's about time to put spark plugs in this thing. This set has a few miles on them. I'll be taking the turbo off for that and a valve clearance check and I didn't really want to put the little GT2560R back on. It's been great but its not efficient beyond about 11 psi. Since the stock clutch and fuel pump seem to be capable of at least 1 bar, I'll be running 1 bar. Looking at the compressor map, this thing is capable of making 450+ rear wheel. I would want to go for a larger and more efficient turbine if I was going to push it that hard, though running in the 300ish horsepower range will be no trouble at all.

Re: Turbo ETA build

The suspiciously inexpensive GT2876R looks like the real deal. It did not come with a wastegate actuator bracket but I think I can sort that out. The compressor inlet is 4 inches in diameter so my intake plumbing will need work too. I hope the compressor housing clears the valve cover, it's definitely larger.

I used a coffee can here on one of the past builds. Some people didn't like that but I never had a problem with it.

Re: Turbo ETA build

Would you think of using a external gate? or is a internal better for what you are doing?

Re: Turbo ETA build

I know turbineresearch was doing 24 PSI at 560 on the OG headgasket. i love the m20 and the m30. when i do research for the m20 turbo i come looking for your post. turbineresearch m30 info is amazing to if you havnt you should check him out he is a cool guy with alot of info. with the m30 turbo's https://www.youtube.com/shorts/JPQpku4x4Z8turbodan wrote: Feb 24, 2023 9:18 PM I've always liked the M20. The M30 is heavier and less fuel efficient. The M20 with the 2.5 top end makes great high rpm power too, whereas the M30 requires more extensive modification for that 6000 RPM+ power. My 2.7i with the GT35R was making peak power at 6400 and it was hanging onto something like 90% of that until 7000. Full boost at 4000 and nothing but fun from there on up. That was probably my favorite aspect of the small six.

As it turns out it's a great motor for boost in terms of durability too. The smaller bore diameter helps avoid detonation and I think the super ETA/2.5 combustion chambers seem to help a little more. I may be mistaken but I think the M30 head gaskets are more delicate. I was doing very well at 21 psi with a stock gasket and head studs. I believe the M30 needs an MLS to approach those boost levels and then you have the usual MLS stuff to deal with. I've had hit and miss results with those, including one that failed only after a buyer had flown in from goddamn Michigan to buy the car and drive it back.

MPG was in the 20s. Best I ever saw was 27. Surely could be better with a more careful tune. This time around I will be using a narrowband 02 sensor for closed loop operation. Easy MPG there.

Re: Turbo ETA build

External works better and is more efficient. Less turbulence at the turbine outlet and a better pressure ratio through the turbine. Internal works pretty well though and simplifies packaging and plumbing. Best ET I ever ran was with the internally gated GT2871R.Notae30 wrote: Dec 25, 2024 8:34 PM Would you think of using a external gate? or is a internal better for what you are doing?

The most efficient system I ever had was the externally gated GT35R. Big turbine, external dump on the wastegate. It made boost with minimal backpressure, which improves the intake/exhaust pressure ratio. Higher volumetric efficiency, greater resistance to detonation. I ran a lot more timing with that system than I could with any of the smaller, internally gated turbos.

Turbine efficiency is not often discussed but it is important. Ten percent here makes a significant difference.

Re: Turbo ETA build

That big-ass compressor housing posed some challenges, but it does fit. I had to make a bracket for the wastegate actuator and the compressor outlet required clearancing the turbine flange and edge of the manifold. I meant to check valve clearances while I was in there but after all of the unexpected fuckery had been sorted out I didn't get around to it.

The boost comes on around 3000 RPM. Feels very good at .8 bar, stronger especially on the top end. I haven't put a wideband on it yet but I did add in a touch of fuel in case it's breathing better.

It's better in a way that it's not trying to spool up everywhere, all the time. I do have to downshift to get down to business now, no more 1500 RPM spoolup. That's okay though, it seems happier with the larger hot side.