Figure it's about time I make an appearance in here. Adam's been keeping you posted with the various changes that have been happening. I've been incredibly busy from April until about a week ago, but in that time I've been working in what I can. If you follow the link in Adam's original post to the build thread for this car in 2012, you can get a pretty good idea of what was done and a lot was done to this car. It received a B35 swap, a recovered interior, a "crack-free" dashboard, a Euro conversion and a pretty comprehensive suspension redo. It all added up to quite a bit of money and effort in this car. I had seen the car at a couple of events at Coast Motor Werk over the years and in talking to the PO, he hardly drove it, putting around 2,000 miles on it in seven years.

With Doug's help, I picked the car up in CA and drove it back to Phoenix. It did well on the trip. Drove pretty well. There were some issues of course, including the rear sway bar sitting in the trunk, several switches inoperable and an annoying hot start issue which also manifested itself as an annoying cold start issue. Oh, also the handbrake didn't work at all. Keeping the car in gear was the only way to keep it from rolling down Doug's slightly sloped driveway. While I already had a growing list of things that were just obvious, I gave the car a pretty thorough inspection once I returned home and gave a list to Adam of what I felt it needed. We worked out a plan for his vision for the car and I had a pretty decent list of needs that were either putting in that extra 10% that should have been done the first time or things that just weren't done properly. Fortunately, the car itself is a solid base to work from and most of the parts and upgrades add value.

The first thing I was really surprised about was the flex disc being installed backwards. New ones actually come with instructions.

Also, there was a leak from the transmission. The selector shaft seal was the culprit there.

The rear sway bar mounts weren't reinforced when the larger Ireland Engineering bars were installed. Reinforced with akumulus' kit. Unfortunately this has created another issue where the ridiculous IE mounting system won't work, but I think I've got a solution for that using standard front mounts.

Moving to the front end, from the receipts and the build thread, the front end parts were new. Unfortunately, the boots were already trashed on the upper arms, both lower control arm to subframe bolts were loose (not wow it's loose, but not snug). Also, particularly frightening was the bolts used for the steering knuckle. Given these bolts have enough trouble with the forces exerted upon them, I was surprised to find these were regular zinc grade 8.8 bolts instead of the black oxide coated grade 10.9 of the originals. UCAs are Meyle HD, lowers are likely Hamburg Technic or something like that. These have all been replaced with Lemförder parts. E31 8-series LCAs and the UCAs have Moosehead Engineering spherical bearings.

Here are the bolts from the steering knuckle. There was some sort of red thread locker on these but the rattle gun hardly broke a sweat removing these. For giggles, a regular ratchet did the trick on the driver side. If Adam doesn't want them, perhaps they can be adopted out as pets.

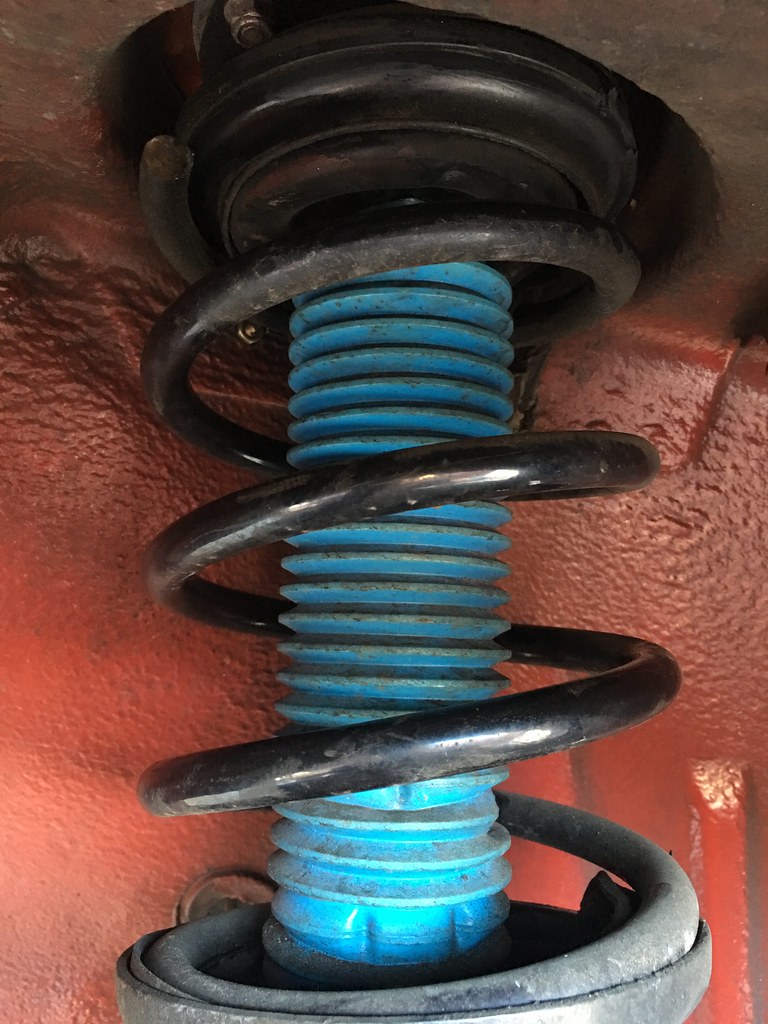

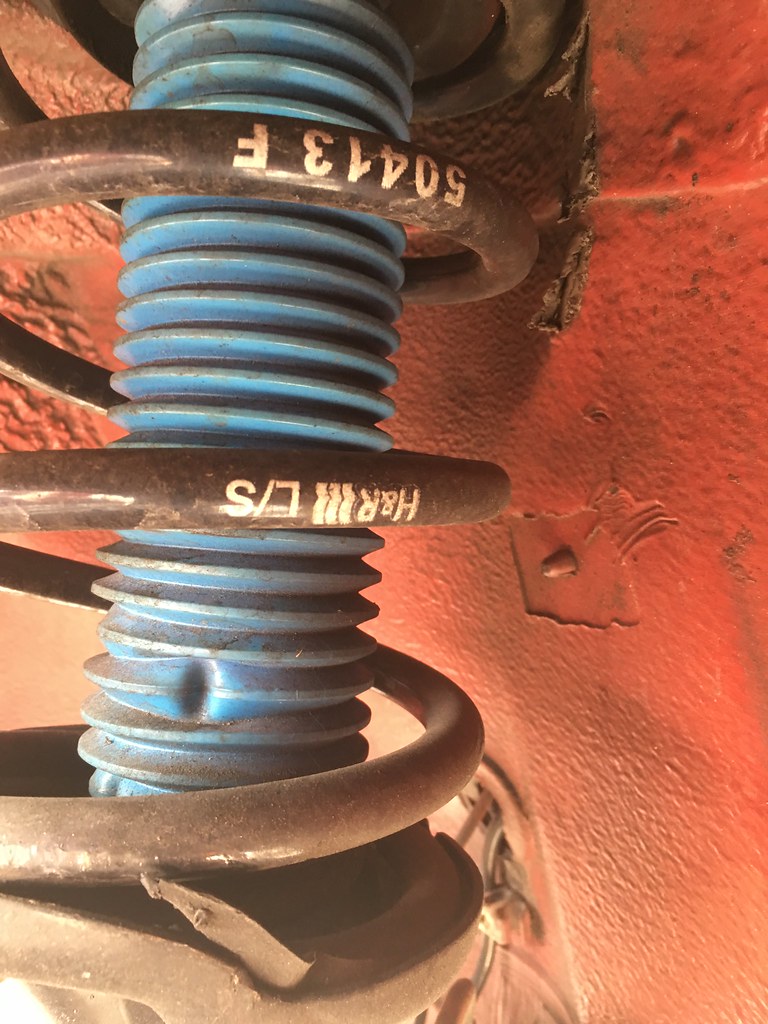

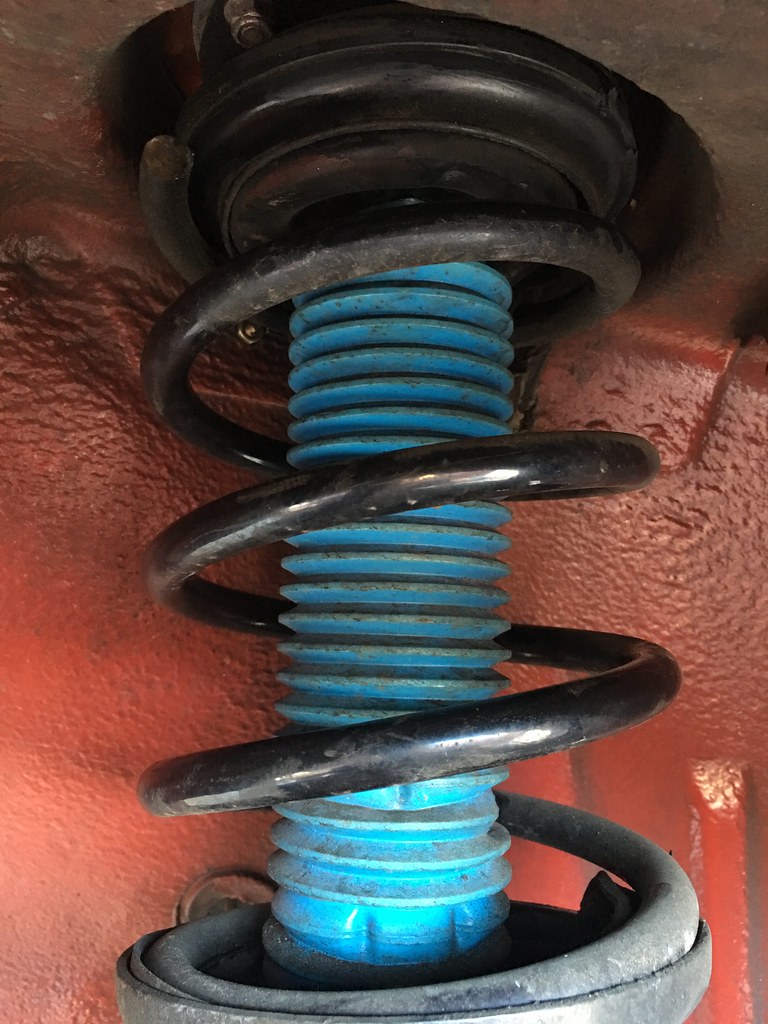

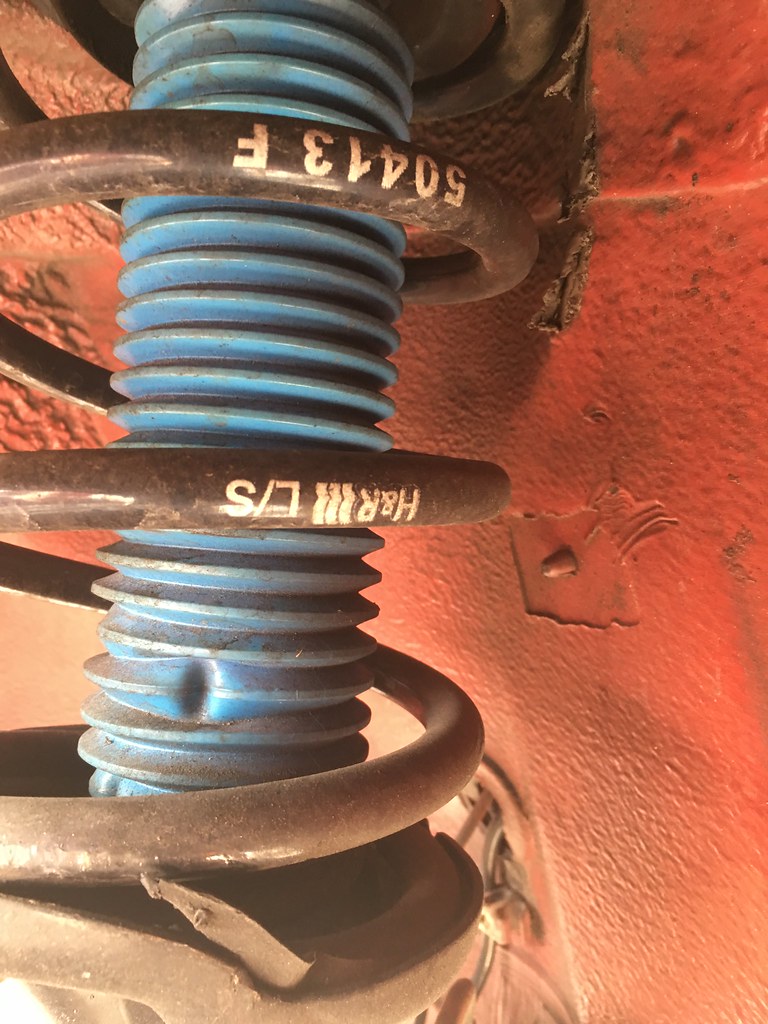

Here are the upside down H&R front springs. One full coil has been cut off each side, springs installed upside down and they shredded the spring pads and my favorite part is when the tail of the spring gets jammed between the mount and the body. Steering wheel springs back at you pretty quickly.

You can see in this photo where there is damage to the schutz.

With the strut assemblies removed, you can see what the tail of the spring did. I was pretty amazed. I look at this as having caught it in the nick of time.

Of course, we couldn't leave that alone, so the loose schutz removed, cleaned thoroughly, etch-primed, schutzed and coated with a mixture of 138 that seemed closest to what was used on the undercarriage of the car.

Is it a perfect job? No. My main concern is sealing and protecting the area so no further damage is done but I do think it came out reasonably well.

I procured a proper set of H&R springs of the same vintage (this way I didn't have to change the rears which actually seem fine). Here's a shot showing the cut spring next to an original.

I was pretty surprised to see the rust on these springs and the spring hats were particularly rusty so I ordered some E90 hats as there are concerns about the altitude change with the removed coil replaced and the springs actually sitting on the spring pads. I'd show you how it looks but I had quite the setback when I discovered this:

Likely a nut with the wrong thread pitch was run onto this with an impact. There were two nuts on this side. One held on with red thread locker and the correct nut on top of it. Given the obvious concerns, I ordered two new strut inserts. Then I can put it all back together. There was also only one washer on each side. The cup was missing from the bottom of the bearing. Fortunately, I had most everything needed in a box in my storage unit.

The AC system in this car is inoperable. From the photos in the build thread, it was obvious nothing was ever done with it, the belt wasn't installed and only one line had been rebuilt previously. The hose to the top of the condenser had clearly ruptured and there is a pretty good collection of oil from that. Of course, there was also this:

While that sorta looks like clearance, uhhh, no. Jay Stratton has the compressor, all of the other lines have been rebuilt and I have a new 533i suction line coming from Germany. This is not going back together like this.

On to happier things, the bodywork on the front end of the car is currently apart.

Everything came apart as it should and I was happy to see the pigtails used for the turn signals and some other things I simply was not expecting. Of course, the splices need to be redone and properly protected but that's child's play. The Euro headlights were installed simply by plugging the US connectors into the lamps. The high beam is no issue there but the low beam was plugged directly into the back of the bulb. Fortunately, I've got some connectors and I'll take the time to properly wire the lamps. Fortunately the new lamps have the proper connection pieces currently missing from the other set.

The good news is that the bumpers are assembled properly and it's nice to see the factory Euro frame rail repair pieces used for this conversion.

Everything should go back together like it should once the early valance and BBS airdam are ready to go. The airdam is currently undergoing the necessary repairs before paint. It was a long struggle to find an original BBS airdam and the piece we got needed plenty of work but it will be worth it in the end.

I have a lot of other things on order like the correct elbow from the airbox to the AFM from an '88-89 E24. This stupid blue silicon joiner thing doesn't fit right. Unfortunately, someone cut off the brackets for the bottom of the airbox, so I'll have to get another one to properly install it. The AFM is just sitting on the bracket on the valve cover, missing all of the connection hardware. All of that will be properly installed in due time. A couple of coolant leaks have been solved along with a fun oil leak.

I'll update the thread with further progress. I almost have everything I need to get the interior set and that will be a fun set of updates.