Broken water pump bolt. What's next?

Broken water pump bolt. What's next?

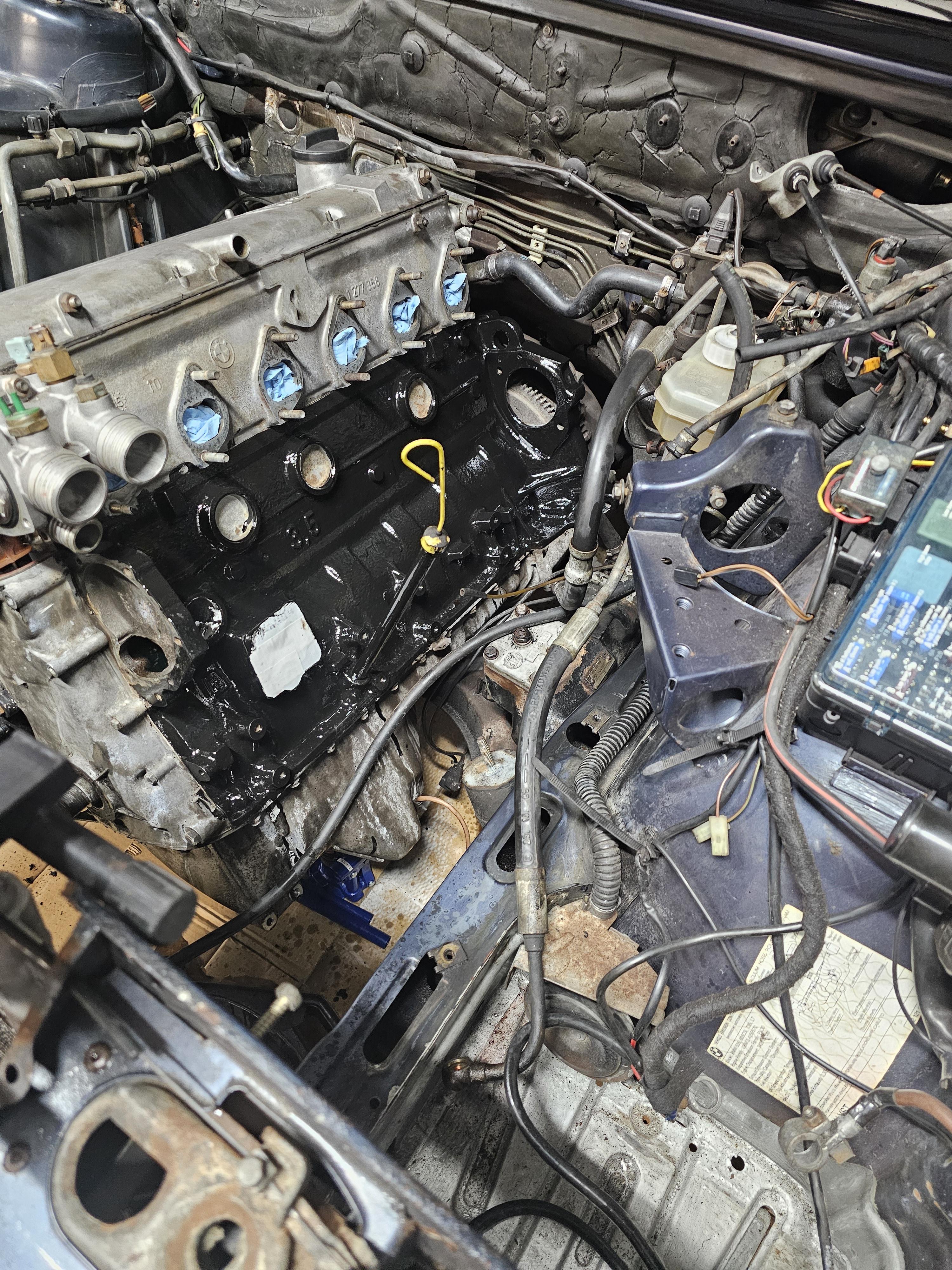

So in my clean up and Vintage prep one of the water pump bolts snapped. It was above the block first but after trying everything it broke again. I was able to weld a nut on top and it started to move a little bit so I started to rock it back and forth slowly and increasing the movement until it eventually snapped again but this time flush with the block. So I went to the hardware store, got a 90 degree drill attachment (there's no room between the condenser and block for the drill and the bit) and two sizes of extractors (#1 and #2) drilled into the remains of the bolt, tapped the extractor with the hammer and using the small adjustable wrench gave it a go and it snapped inside the bolt that's inside the block.

So, now what? I'm out of options as I have also to deal with the broken extractor too.

What's the group wisdom in this situation?

https://imgur.com/gallery/nyaoCHt

So, now what? I'm out of options as I have also to deal with the broken extractor too.

What's the group wisdom in this situation?

https://imgur.com/gallery/nyaoCHt

Re: Broken water pump bolt. What's next?

I would drill out the bolt as carefully as possible, trying not to destroy the threads in the process. Worst case, drill and tap it for either a thread repair insert or the next size larger bolt.

The remaining threads don't need to be perfect, as long as they hold torque.

The remaining threads don't need to be perfect, as long as they hold torque.

Re: Broken water pump bolt. What's next?

If you look closely, the extractor is now snapped inside the drilled remnants of the bolt.

That's my current predicament

That's my current predicament

Re: Broken water pump bolt. What's next?

You'll have better luck with a center punch and trying to crack it into pieces than using a smaller drill, it'll just catch and snap off again.

But if it was me the first thing I'd try is bolt it up, and leave that one bolt out. With Permatex #3 of course on both sides of the gasket and anti seize on the bolts. Castings have good rigidity albeit with low strength, so it might not leak. If it does you're back where you started. The easy out is crazy hard of course, but even the cast iron block is pretty hard and doesn't like to be drilled.

But if it was me the first thing I'd try is bolt it up, and leave that one bolt out. With Permatex #3 of course on both sides of the gasket and anti seize on the bolts. Castings have good rigidity albeit with low strength, so it might not leak. If it does you're back where you started. The easy out is crazy hard of course, but even the cast iron block is pretty hard and doesn't like to be drilled.

-

Blue Shadow

- Posts: 10292

- Joined: Feb 12, 2006 12:00 PM

- Location: SE PA

Re: Broken water pump bolt. What's next?

The water system isn't under high pressure, 1 atm, so you should be able to prevent leaks with proper install with a sealant as Mike mentioned. Hope this goes well. Report back your results.

-

Fanclutchnut

- Posts: 146

- Joined: Jan 05, 2021 7:32 PM

- Location: Westchester Co NY

Re: Broken water pump bolt. What's next?

Why not try the nut weld option again? I’ve see if done where a washer is placed between the nut and block to create a bearing surface and welding shield. I’d turn up the heat and down the wire so that it really penetrates. I understand that the heat from the arc does as much for the removal as having a solid nut to put a wrench on.

Good luck!

Good luck!

Re: Broken water pump bolt. What's next?

The problem with this is that I would need to support somehow the washer and the nut while also getting the MIG tip in there. Not much room plus how to hold the 2 pieces (nut and washer) in place since this is vertical is a challenge on it's own.Fanclutchnut wrote: Mar 17, 2024 10:22 AM Why not try the nut weld option again? I’ve see if done where a washer is placed between the nut and block to create a bearing surface and welding shield. I’d turn up the heat and down the wire so that it really penetrates. I understand that the heat from the arc does as much for the removal as having a solid nut to put a wrench on.

Good luck!

I'll keep chugging along with other things while my mind works on a solution before doing the "let's bolt it up and hope it seals" one.

In the mean time, the left side of the block is painted (that POR-15 engine enamel is VERY glossy) and just put the painted B35 intake manifold and oil filter housing in place to see how it will all look. I'll be painting the B35 valve cover to match and thinking about the filter housing cover too.

Is the blue too blue? It's called Blue Flame from Cerakote and its an air cured ceramic paint. I still need to do a clear cote over it

-

Fanclutchnut

- Posts: 146

- Joined: Jan 05, 2021 7:32 PM

- Location: Westchester Co NY

Re: Broken water pump bolt. What's next?

I’ve see it done with crazy glue. Glue the washer to the block and then the nut to the washer. The washer also allows you to use a larger nut making it easier to get the nozzle in there.

Re: Broken water pump bolt. What's next?

That's actually a very good idea! Do you think the weld will stick to the broken extractor or should I attempt to break it and remove it?

-

athayer187

- Posts: 1623

- Joined: May 10, 2006 11:27 AM

- Location: Cheshire, CT

Re: Broken water pump bolt. What's next?

Weld will stick to the extractor. Half of the magic of welding to the existing fastener is the significant amount of heat you dump into the broken fastener while welding.

Re: Broken water pump bolt. What's next?

Welding to the extractor will also take the temper out of it so it may become soft enough to drill, provided you do not quench it. If you do that it will become glass-hard and shatter as soon as you try to put any torque on it. Heat is generally your friend with this stuff though.

Re: Broken water pump bolt. What's next?

I was rereading this and just thinking about the temper on the easy out when I read your post. That might be doable. Maybe, and then drill it. Might be worth a superficial one to experiment on. If you could quench it effectively enough, you could then shatter it and remove it. I don't think the block would be in danger as it's so large a heat sink.gadget73 wrote: Mar 19, 2024 8:57 AM Welding to the extractor will also take the temper out of it so it may become soft enough to drill, provided you do not quench it. If you do that it will become glass-hard and shatter as soon as you try to put any torque on it. Heat is generally your friend with this stuff though.

I'd still try bolting it up missing one first, but other options.

Re: Broken water pump bolt. What's next?

Thanks everyone for your ideas on how tackle this and /or possibly just bolting it with that one missing bolt. I have to do a quick trip to Greenville, SC tomorrow and return Thursday night so any additional wrenching will be this weekend.

Re: Broken water pump bolt. What's next?

Iron block won't care about that, the risk is more a thermal shock thing. Get the tool hot enough to harden and then squirt it with water might cause enough stress in the block to crack something. Annealing it wouldn't be such a big deal since it won't get shocked with water.

Mike W. wrote: Mar 19, 2024 12:35 PMI was rereading this and just thinking about the temper on the easy out when I read your post. That might be doable. Maybe, and then drill it. Might be worth a superficial one to experiment on. If you could quench it effectively enough, you could then shatter it and remove it. I don't think the block would be in danger as it's so large a heat sink.gadget73 wrote: Mar 19, 2024 8:57 AM Welding to the extractor will also take the temper out of it so it may become soft enough to drill, provided you do not quench it. If you do that it will become glass-hard and shatter as soon as you try to put any torque on it. Heat is generally your friend with this stuff though.

I'd still try bolting it up missing one first, but other options.

Update: Re: Broken water pump bolt. What's next?

Well, remember this broken bolt that didn't leak back then? Well now after another failed attempt to try to remove it (since the block was out and I had more room) it started weeping a little bit even without having the engine run. Just got some new water pump gaskets (bought two just in case).

What should I do to try to fix this (engine is in the car now so not much room there), just make sure everything is clean, put a layer of RTV, tighten it and let it cure overnight before putting coolant in the engine?

Really, really want to make sure this doesn't leak and I can start and run the newly overhauled engine!

What should I do to try to fix this (engine is in the car now so not much room there), just make sure everything is clean, put a layer of RTV, tighten it and let it cure overnight before putting coolant in the engine?

Really, really want to make sure this doesn't leak and I can start and run the newly overhauled engine!

Re: Broken water pump bolt. What's next?

Oh no...

I would apply a coat of something like Hondabond 4 on both sides of the gasket and install immediately while it's still wet. Slap it on the block and run the bolts in finger tight but do not torque it immediately. Let it set up for half an hour and then tighten the bolts up.

If you ever have the engine out again, that's the time. It may take several hours but that situation needs to be addressed.

Did you use sealant when you installed the pump last time? Without that bolt I would expect leakage. Its amazing how much these aluminum castings can bend. Every other bolt can be snugged up tight but without that one you'll have very little clamping force over that area of the gasket.

I would apply a coat of something like Hondabond 4 on both sides of the gasket and install immediately while it's still wet. Slap it on the block and run the bolts in finger tight but do not torque it immediately. Let it set up for half an hour and then tighten the bolts up.

If you ever have the engine out again, that's the time. It may take several hours but that situation needs to be addressed.

Did you use sealant when you installed the pump last time? Without that bolt I would expect leakage. Its amazing how much these aluminum castings can bend. Every other bolt can be snugged up tight but without that one you'll have very little clamping force over that area of the gasket.

Re: Broken water pump bolt. What's next?

turbodan wrote: Jan 02, 2025 10:51 PM Oh no...

Slap it on the block and run the bolts in finger tight but do not torque it immediately. Let it set up for half an hour and then tighten the bolts up.

X2, the above is critical. Don't torque it down at first. RTV is good for applications like this, but others are better, likely including the one turbodan mentioned.