Page 1 of 1

Cool product for MS users

Posted: Nov 03, 2008 3:03 PM

by Brad D.

I found this browsing around on e30tech and just wanted to post it for the few adventerous MS users here. For those wanting to run full sequential having a cam sync signal is required. This is done off of the cam but there was no over-the-counter solution for integrating a cam trigger, requiring you to "roll your own" trigger. This cool distributor cover allows a bolt on solution for a crank trigger. I would guess a ferrous "tooth" would be required on the cam snout where the rotor would normall bolt but that is a relatively easy proposition. Unfortunately I can't read Swedish and an online translation doesn't help a whole lot so I don't know if it includes a sensor or what type is required if it doesn't. But the unit is about $100USD so it it pretty reasonable.

PRD Motorsport Cam Cover

Posted: Nov 03, 2008 3:56 PM

by turbodan

That is cool. Great way to get rid of the distributor.

Posted: Nov 04, 2008 6:22 AM

by FirstFives Dictator

I can't get the link to come up.

Actually I'm lukewarm about cam trigger for M20/M30.

60-2 wheel with MS2Extra's

Every Tooth Decoder yields some really good sync. Cam trigger would probably lengthen my start times with the existing code.

I'm really picky about having a car that starts quickly. IE: a worn RX7 motor would drive me to insanity.

Posted: Nov 04, 2008 11:45 AM

by Brad D.

FirstFives Dictator wrote: IE: a worn RX7 motor would drive me to insanity.

I understand what you mean. If nothing else, like Dan said, it would make a cool block off plate if you were running wasted spark.

Posted: Nov 04, 2008 12:20 PM

by Ken H.

Paul B. already has these. contact PB for more info.

Posted: Nov 04, 2008 12:32 PM

by Brad D.

Thanks for the heads up Ken!

Posted: Nov 04, 2008 12:39 PM

by FirstFives Dictator

Big Bronze Rim wrote:FirstFives Dictator wrote: IE: a worn RX7 motor would drive me to insanity.

I understand what you mean. If nothing else, like Dan said, it would make a cool block off plate if you were running wasted spark.

A family ran this car in all 3 heats Sunday with open exhaust.

Nice latino family, but my ears still hurt. Listening to that rotary turn over to build compression was painful, but more painful when it caught.

Our boy on the other hand drove a civilized car with crappy bosal exhaust.

That's A6's do to 550# springs. I thought I was going to scrape the door handles.

Posted: Nov 04, 2008 12:41 PM

by Shawn D.

FirstFives Dictator wrote:That's A6's do to 550# springs.

Huh?

Posted: Nov 04, 2008 12:45 PM

by Brad D.

My brother is into RX-7s so I know the "crank it forever 'till it chatches" routine well. At least his is a fresh rebuild and does so pretty quickly and is turbo so it's not as loud and obnoxious as an NA car. I can only imagine how loud that was.

Posted: Nov 04, 2008 12:56 PM

by FirstFives Dictator

Shawn D. wrote:FirstFives Dictator wrote:That's A6's do to 550# springs.

Huh?

Dang, can I take a makeup quiz?

Should be :

That's what Hoosier A6's do to 550# springs

Posted: Nov 12, 2008 4:21 PM

by Bruno

Ken H. wrote:Paul B. already has these. contact PB for more info.

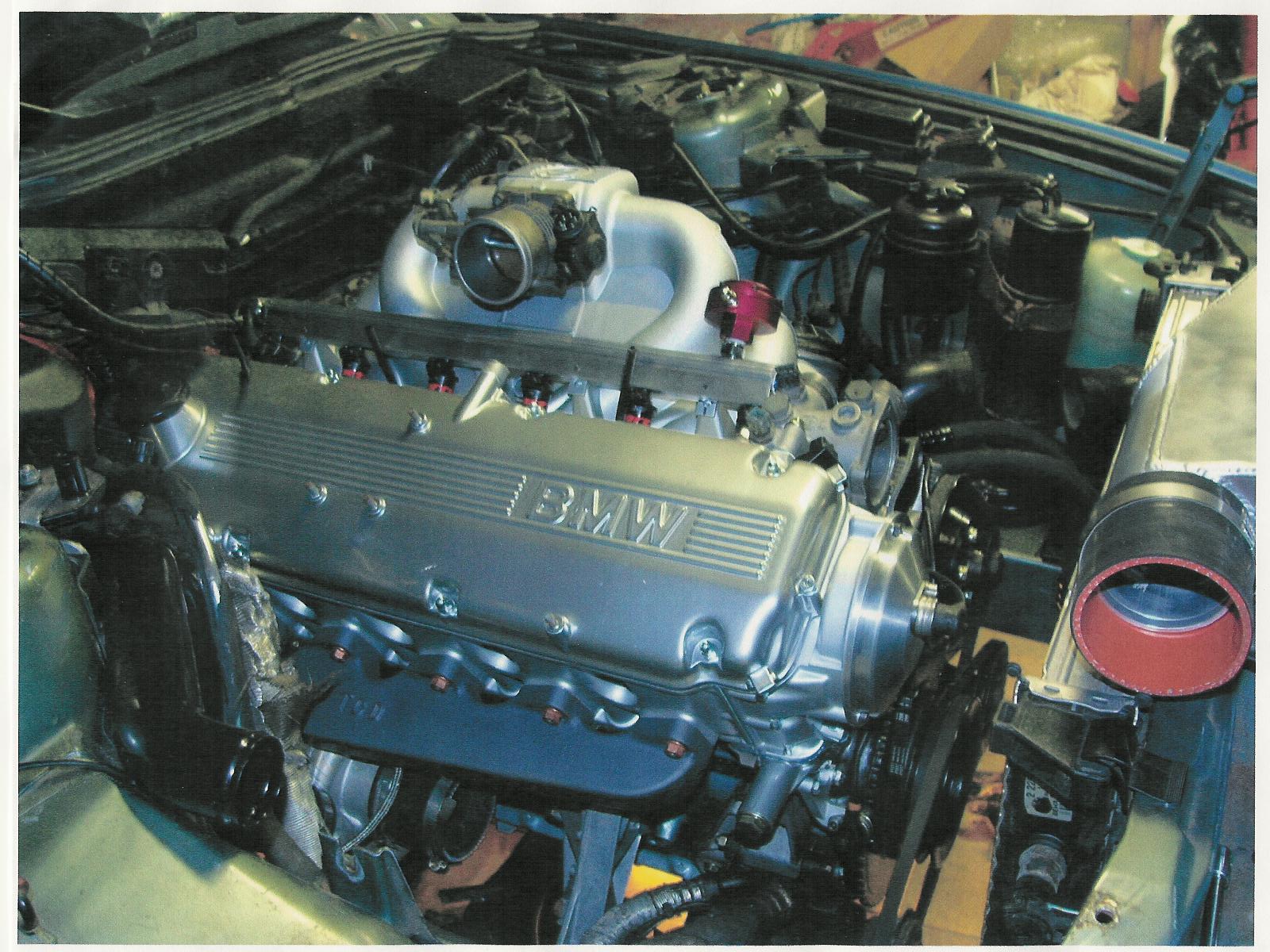

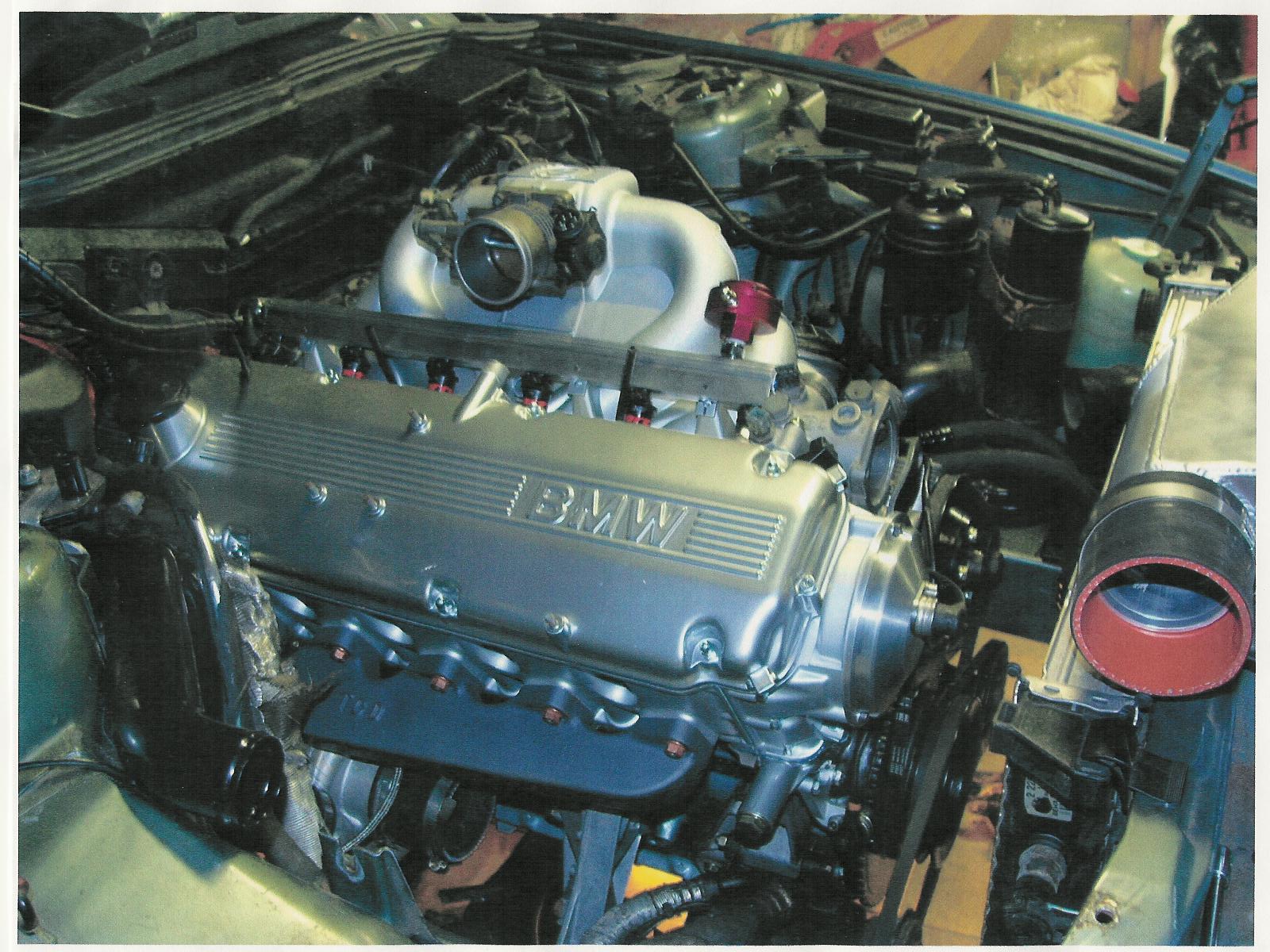

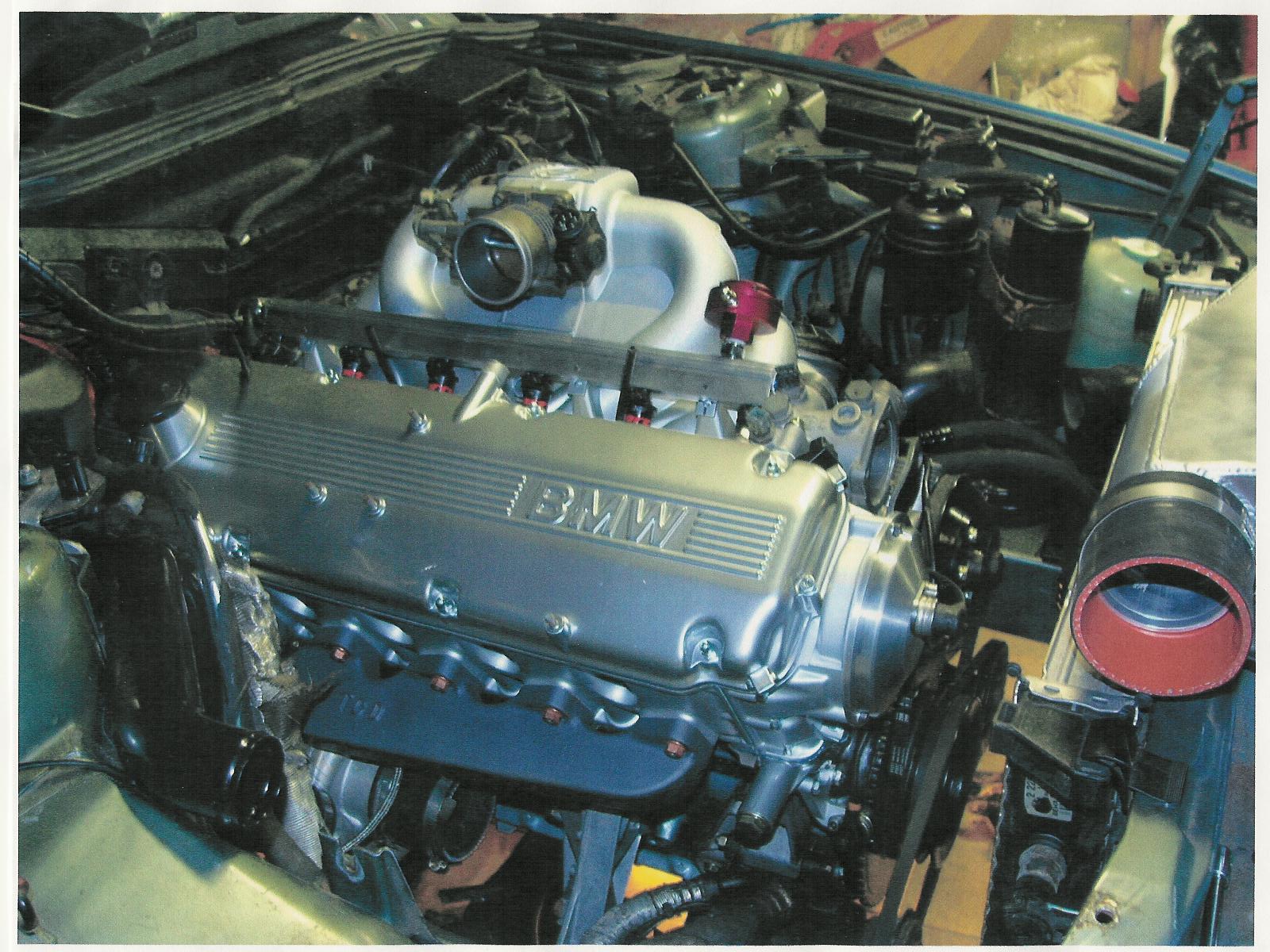

I was considering going sequential with individual coils, but I am not sure that it will change much on the race car (turbo 635csi with M30 engine), I am running wasted spark with 3 coils and have no problems.

Posted: Nov 12, 2008 7:18 PM

by paul burke

Bruno, If you chose to control fuel/spark to each cylinder it comes in very handy. Some systems are set up to take advantage of this. All cylinders do not like the same timing curve and/or fuel delivery.

Paul

Posted: Nov 12, 2008 8:53 PM

by Ken H.

paul burke wrote:If you chose to control fuel/spark to each cylinder it comes in very handy. Some systems are set up to take advantage of this. All cylinders do not like the same timing curve and/or fuel delivery.

One of the lesser-known but more attractive features of the Electromotive TEC-3r is the ability to do individual cylinder tuning once the basic maps are established.

The TEC-3r will allow individual adjustments to injector duty cycles and pulse widths, so the degree of finesse here is pretty impressive. This is really nice where you have individual throttle bodies, but it applies as well, maybe more so, on the M30-type intake plenum.

This is because the design of the multi-runner M30 creates inherent imbalances in quantitative delivery of the air/fuel emulsion to the individual ports.

By adjusting the timing at a per-hole level, it's possible to even out the individual cylinder's dynamic operating pressures and achieve a more consistent power delivery. Not necessarily

more power, but smoother and more consistent.

This means the crank is accellerated in a more uniform manner with each power stroke and internal parasitic losses due to cylinder pressure imbalances get reduced.

Another point worth noting is the BMW camshafts are a fairly flexible in torsion as a mechanical object. This is exacerbated by the pressures from the valve springs pushing on one side of the cam, thru the rocker arms, as it were. So it's entirely possible for #1 cylinder to be set up spot-on as to cam timing, but #6 could be as much as 4 degrees off. This isn't due to sloppy workmanship or questionable materials, but rather because of the effect of torque on the shaft itself. If you were to pull the cam and examine it on a surface plate and Vee-blocks with a dial indicator, the amount of deflection between the individual sets of lobes would be minimal; the "error" shows up under load and at speed.

Paradoxically, you probably wouldn't see this in a SBC or Ford as the valve spring pressures from the opposing banks tends to offset the distortion. But in an inline OHC layout, the effects are quite noticeable.

One of Paul's "demon tweaks" that can be done to his custom cams is setting them up to have ever-so-slightly different duration, lobe separation and/or overlap on each individual hole. This means the per-cylinder timing is going to be somewhat different--an issue which a coil-per-cylinder layout and multiple driver (TEC-3r) can readily address.

This arrangement (tweaked cam) can be applied to both SOHC and DOHC layouts; the benefit showing up more on the DOHC because of the greater pressures from the 2 sets of springs on both Intake and Exhaust, altho' the S38's "flat tappet" arrangement tends to mitigate this, while the M30's rockers work to the opposite result.

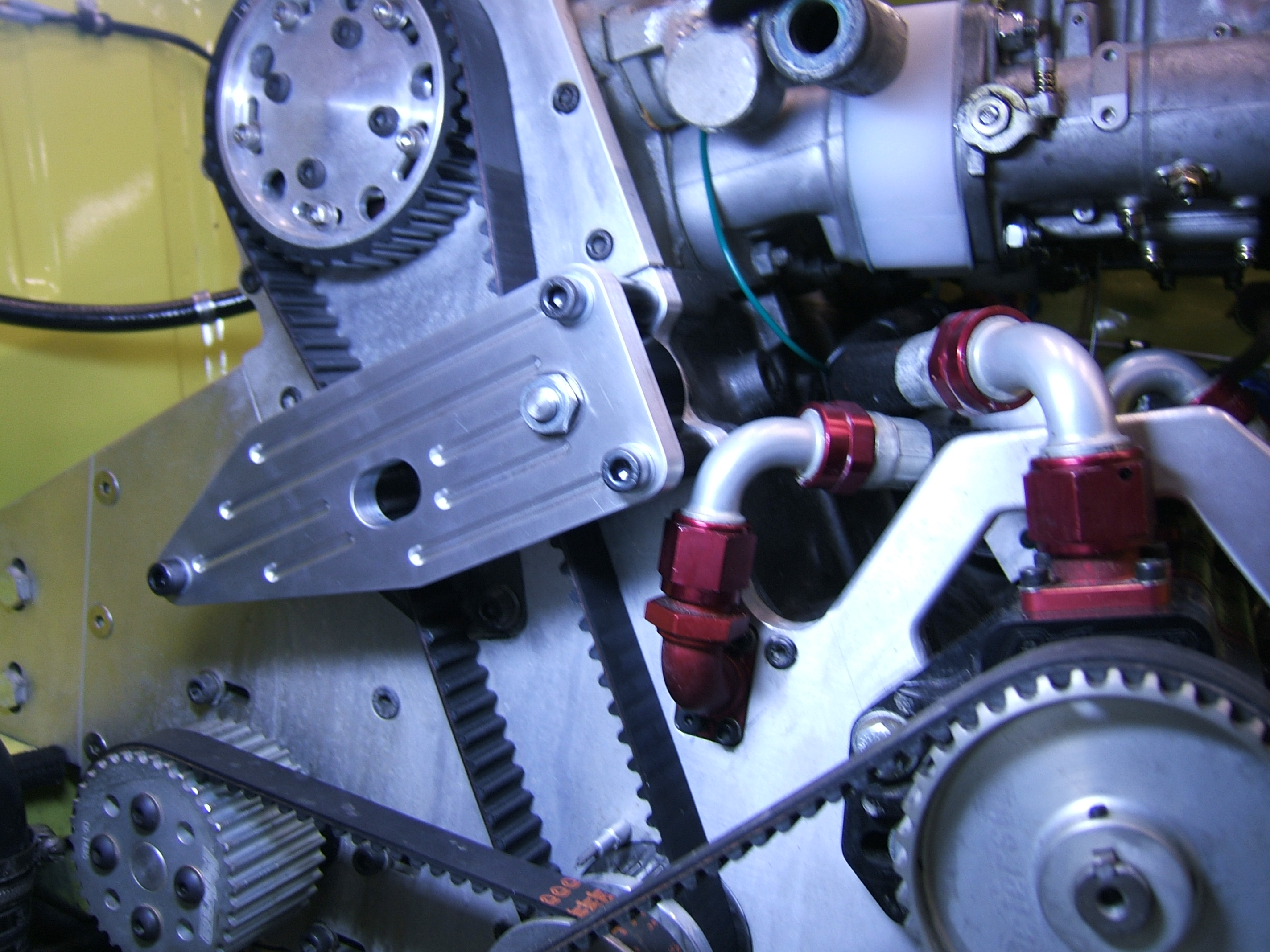

Adding to the variables and the finesse which can be applied to the valve timing, Paul's method of setting the cam timing gear allows getting well within 1/4 of 1 degree of accuracy.

This has the cam gear proper being sandwiched between two locating rings and secured by multiple allen bolts; the cam gear itself having an a series of annular slots to allow for adjustment in timing, and the pieces secured by the allen bolts. The amount of advance or retard on the cam is determined using a precision vernier protractor, Additionally, piston depth in relation to TDC is set by use of a "location plate" and feeler gauges.

I don't have the link handy, but this was shown with a set of really good pictures on one of Duke's threads when he was in the process of setting up his turbo. The "Search" function might help here.

The amount of cam timing offset is indicated by a series of witness punch marks. These are very precisely placed, so with proper attention to detail, the spacing can be "split," and the timing set to the desired values.

HTH

Posted: Nov 12, 2008 9:07 PM

by Brad D.

Excellent info Ken.

Posted: Nov 12, 2008 10:46 PM

by paul burke

Actually Ken, the "witness punch marks" are placed with a tiny ball mill in a degreed rotary table. Good read !

Paul

Posted: Nov 12, 2008 10:48 PM

by Ken H.

Paul, do you have a picture of this? I went looking in my files and can't find it.

Thx

Posted: Nov 12, 2008 10:57 PM

by paul burke

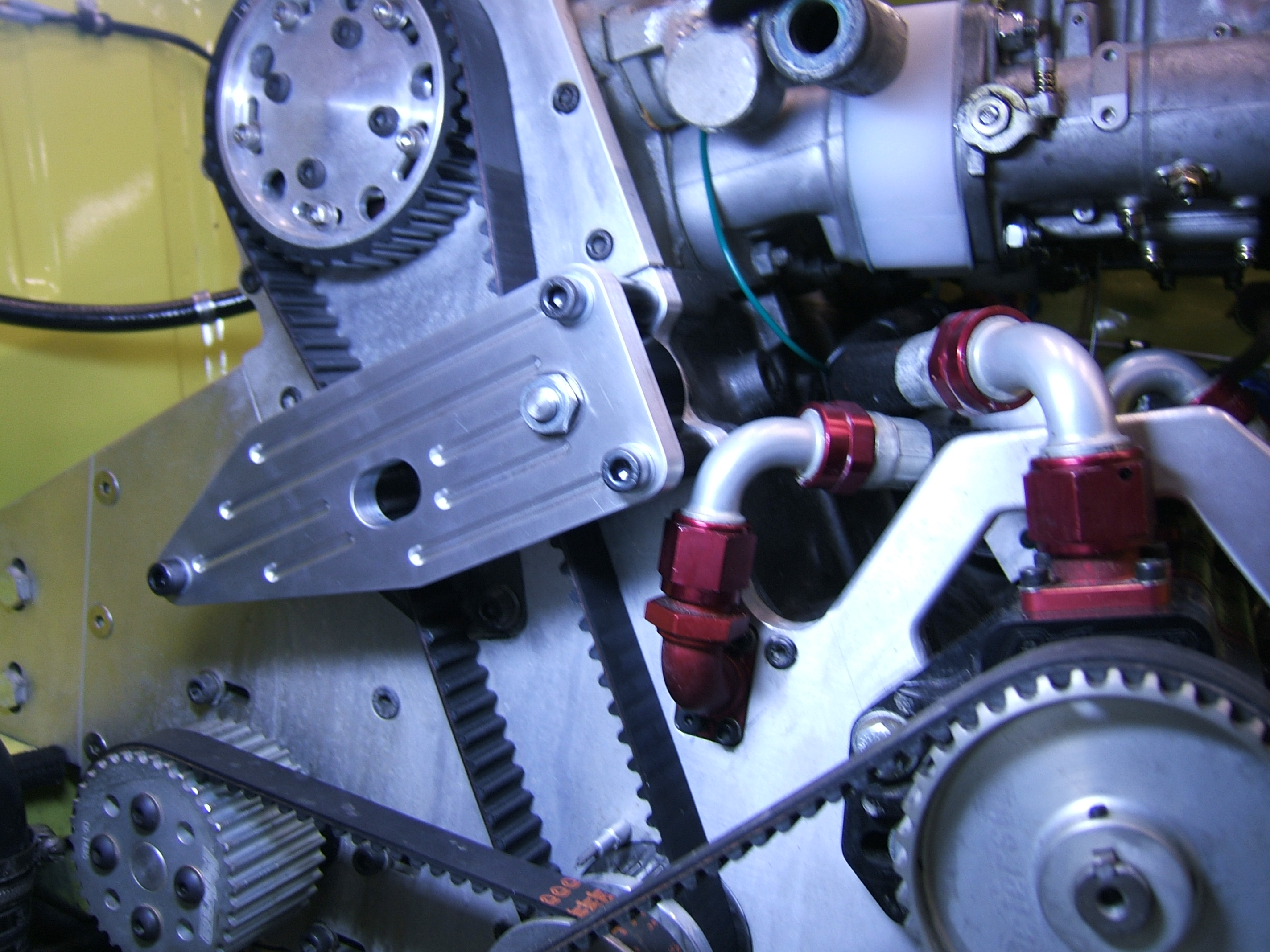

This is the only one I saved.

Here is the one on the M-10 belt drive conversion. (m-30 also)

I am looking for the M5/6 one. I think I may have lost It.

Paul

Posted: Nov 12, 2008 11:06 PM

by Ken H.

Posted: Mon Mar 05, 2007 6:14 pm Post subject:

--------------------------------------------------------------------------------

Martin in BellevueWA wrote:

Certainly document dialing the cam. It is an interesting thing. There are only a couple of adjustable cam gears out there for the m30. I had one from Korman, which didn't work on the m30b35. Jeff N used one from metric mech, with varying degrees of success. This was primarily due to Jim Rowe's inability (I think, instead of unwillingness) to describe the cam sold with the 'sport' m30 head. At one point, Jeff was happiest with a supposed 8 degrees of cam advance, fighting pinging, with the poor midrange.

Thanks Paul. The following is from a post Duke put up back around 5 March, 2007 and included the photo of the adjustable cam gear.

Paul Burke is making me a custom adjustable Cam sprocket.

The side you are looking at receives the four bolts. They pass through a second plate that has the actual sprocket teeth and that plate has slots for the bolt holes. The dots you see at the bottom are for adjusting the cam. Each dot is 2 degrees advanced one way or retarded the other. The reference dot is on the moving sprocket plate and the other timing marks are on the fixed cover plate. So the cam sprocket is sandwiched between the cam mounting plate and the front plate. Just loosen the four bolt and the sprocket can be adjusted.

Posted: Nov 12, 2008 11:22 PM

by paul burke

Ken, now that we have completely stolen this thread,I will add that you can adj. cam timing without removing front cover. At TDC the timing marks appear in the area above the cover and the bolts are accessible from top.That is the main reason for this design.

Paul

Posted: Nov 12, 2008 11:24 PM

by Brad D.

Don't worry about "stealing" this thread. This is excellent information and quite relevant. It's great to have this type of meaty discussion here. I love it.

Posted: Nov 13, 2008 12:07 AM

by paul burke

Started on one for the M20, sidelined due to lack of interest.

Paul

Posted: Nov 13, 2008 3:30 AM

by red535t

any chance of taking it to the next level?

like fitting an advancing type of gismo on the cam sprocket?

a semi v-tec setup might pay good dividends.

its been awhile since my last posting.

engine still in pieces.

marty

Posted: Nov 13, 2008 12:39 PM

by paul burke

Marty, I suppose I could challenge myself and build some kind of mechanical RPM related retard gear. The question is would anyone buy it? Although I do my fair share of engine builds, there doesn't appear to be much interest in the individual parts.

Paul

Posted: Nov 13, 2008 1:38 PM

by Jeremy

paul burke wrote:The question is would anyone buy it?

The answer, like so many other things in this world: it depends.

Would variable cam timing be worth anything on a single cam motor? It'd be worth some gains on the m88/s38 I'd imagine, but what would the gains be? At what cost?

It'd certainly be cool.

Marty, these are BMWs, not Hondas. Let's say "like VANOS" rather than "like V-Tec".

Jeremy

Posted: Nov 13, 2008 4:53 PM

by red535t

Jeremy wrote:paul burke wrote:The question is would anyone buy it?

The answer, like so many other things in this world: it depends.

It'd certainly be cool.

Marty, these are BMWs, not Hondas. Let's say "like VANOS" rather than "like V-Tec".

Jeremy

cheers for clearing that up; was a bit late last night and

couldnt think of the bimmer equivelent

Re: Cool product for MS users

Posted: May 27, 2015 4:16 PM

by bornagain

Hey i know this thread has been dead for a couple years now but i ws curious if there is still cam sensors that either paul burke is still making or other people or if you have made one off cam sensors im interested in pictures. im running MS3X and was hoping to have the fuel full sequential because of the large injectors. Thanks

Re:

Posted: Jun 05, 2015 2:03 AM

by crispy

Ken H. wrote:paul burke wrote:Another point worth noting is the BMW camshafts are a fairly flexible in torsion as a mechanical object. This is exacerbated by the pressures from the valve springs pushing on one side of the cam, thru the rocker arms, as it were. So it's entirely possible for #1 cylinder to be set up spot-on as to cam timing, but #6 could be as much as 4 degrees off. This isn't due to sloppy workmanship or questionable materials, but rather because of the effect of torque on the shaft itself. If you were to pull the cam and examine it on a surface plate and Vee-blocks with a dial indicator, the amount of deflection between the individual sets of lobes would be minimal; the "error" shows up under load and at speed.

Ha- I always wondered about that. I wondered if BMW accounted for it. Seems like something BMW would have done, but I guess not...