Re: 1985 Arktisblau M535i Renovation - Progression

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

From what I've seen from a mellow glance, it looks pretty spectacular. I'm sure even the most die hard self absorbed restoration guy would commend you on your extreme detail oriented cosmetic and functional works.

I like that Arctic Blue color (I'm partial, but mine is so blown out it's starting to look kind of cool on top... But I'd prefer it shiny I figure like yours).

Surely I will be looking more later at your tome of work documented here!

I like that Arctic Blue color (I'm partial, but mine is so blown out it's starting to look kind of cool on top... But I'd prefer it shiny I figure like yours).

Surely I will be looking more later at your tome of work documented here!

-

maybeillbuyit

- Posts: 535

- Joined: Feb 01, 2014 12:00 PM

- Location: Vancouver BC

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Very nicely done. I just read through all of the latest install pics. Love the seats of course. Seeing that Taurus makes me wonder why nearly every e28, e24, e12 is always black , beige or blue. I surprises me more people didn't opt for some of these other colors. I'm hoping to see this car in person some day. Congrats

Maybe I missed it , whats your feeling on all the sound deadening etc. Is the car a quiet as you hoped? I assume its made a fair bit of difference.

Maybe I missed it , whats your feeling on all the sound deadening etc. Is the car a quiet as you hoped? I assume its made a fair bit of difference.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

I have only driven it short distances, both street and freeway and it is noticeably quieter (or at least I really want it to be). Of course, I have no real scientific method of comparison since I didn't create a baseline. I have also not driven any long distances yet and that is where I tend to notice the differences.maybeillbuyit wrote: Dec 17, 2021 12:04 PMMaybe I missed it , whats your feeling on all the sound deadening etc. Is the car a quiet as you hoped? I assume its made a fair bit of difference.

I could have likely skipped one or two items I used but overall, I have to say it is making a marked difference and probably worth the cost expense in the long run.

-

stuartinmn

- Posts: 9472

- Joined: Feb 12, 2006 12:00 PM

- Location: Minneapolis

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Do you have a part number for those door wiring boots from Ivo? I looked around on his website but wasn't able to find them.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

That was harder than it should have been to find: https://www.e28.nl/en/product/bmw-e28-f ... 121380229/stuartinmn wrote: Dec 19, 2021 11:56 PM Do you have a part number for those door wiring boots from Ivo? I looked around on his website but wasn't able to find them.

-

stuartinmn

- Posts: 9472

- Joined: Feb 12, 2006 12:00 PM

- Location: Minneapolis

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Thanks for the link! I'll order a couple of them today.

Back when I restored my M535i I was able to find an aftermarket part that doesn't look original but worked reasonably well for the rear doors, but nothing that would have worked for the fronts. It was a part from Spal, but it appears that one is NLA. https://www.mye28.com/viewtopic.php?f=3 ... 8&p=758424

Back when I restored my M535i I was able to find an aftermarket part that doesn't look original but worked reasonably well for the rear doors, but nothing that would have worked for the fronts. It was a part from Spal, but it appears that one is NLA. https://www.mye28.com/viewtopic.php?f=3 ... 8&p=758424

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

As I mentioned in the last post, supposedly Ivo has reproduced the rear boots (or at least the prototypes). However I looked all over the site couldn't find them; it doesn't mean they're not there, look how hard it was to find the fronts, but maybe they're not ready for primetime sales yet.

-

stuartinmn

- Posts: 9472

- Joined: Feb 12, 2006 12:00 PM

- Location: Minneapolis

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

I placed my order. The front boots are reasonably priced, but shipping costs to the US...oof.

-

stuartinmn

- Posts: 9472

- Joined: Feb 12, 2006 12:00 PM

- Location: Minneapolis

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

As a followup to my previous post, the door wiring boots from Ivo arrived today. They appear to be very good quality, and I was amazed at the fast shipping time (only nine days from the Netherlands to Minnesota.) Thanks again for the tip.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Glad to hear it. I am continually amazed at how fast shipments from EU (usually via DHL) get here. My latest order from Schmiedmann in Denmark to Los Angeles only took about 4 days. And yet orders within the continental US (doesn't matter which carrier), takes a week or more to go from one coast to the other. Go figure.stuartinmn wrote: Dec 29, 2021 3:00 PM As a followup to my previous post, the door wiring boots from Ivo arrived today. They appear to be very good quality, and I was amazed at the fast shipping time (only nine days from the Netherlands to Minnesota.) Thanks again for the tip.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Beautiful work, and the new color/leather interior is stunning!

Re: 1985 Arktisblau M535i Renovation - New Year's Update

What brand of brake pistons did you use? And did you cover the inside where the piston comes in during the zinc/galvanizing process, or is it not necessary?

Last edited by Alberto89 on Feb 23, 2022 11:49 AM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Brake Caliper Pistons: Stock ATE that came with the calipers

Plating Protection: Not sure what the plater did but the zinc didn't get into the shafts/wells. There was a discussion on that before that it was perfectly okay for the zinc coating to line the shafts/wells; so I would say it is not critical.

Plating Protection: Not sure what the plater did but the zinc didn't get into the shafts/wells. There was a discussion on that before that it was perfectly okay for the zinc coating to line the shafts/wells; so I would say it is not critical.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Okay thanks. Have you sanded or polished the cylinder walls? I can't find Ate pistons on the internet hence my question.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

No I didn't have to, if I recall I might have sourced these as rebuilt units and sent back my cores (I didn't want to clean the old ones). Then I disassembled them for plating, then rebuilt them myself. The interior cylinder walls were in good clean condition (so were my old ones since the fluid was regularly changed). I did a minor upgrade change when I did this by replacing the rears with E34 540i calipers in lieu of the E32 735i ones that my car came with (it mattered what rebuild kit you use).Alberto89 wrote: Feb 23, 2022 6:08 PM Okay thanks. Have you sanded or polished the cylinder walls? I can't find Ate pistons on the internet hence my question.

I am not sure you're going to find the cylinders separated for sale individually at this point. Your best bet might be to do what I did and buy used rebuilt clean units and plate those and use all the parts that come with them.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Okay, thank you for the information!

Re: 1985 Arktisblau M535i Renovation - Next Chapter

I'm trying to do only a partial part of what you did and just need to get the carpet pulled up in the driver and passenger footwells but it seems like I'm going to have to dismantle the entire center console to get the clearance. Any advice on locating hidden fasteners in the center console? I can get things mostly loose but it feels like it's going to break tabs and such if I pull harder. Not sure if the wiring harnesses are holding things tight.

Re: 1985 Arktisblau M535i Renovation - Next Chapter

Understandable, there are several blind connections that you don't find until you start taking things apart. You can see some of them in my photos.JoelTell wrote: Oct 14, 2022 4:32 PM I'm trying to do only a partial part of what you did and just need to get the carpet pulled up in the driver and passenger footwells but it seems like I'm going to have to dismantle the entire center console to get the clearance. Any advice on locating hidden fasteners in the center console? I can get things mostly loose but it feels like it's going to break tabs and such if I pull harder. Not sure if the wiring harnesses are holding things tight.

The first thing to do is disconnect all the various cables, wires, clips etc. including:

-Window Switches, push the wire harnesses through the holes to free up the console.

-Seat Switches (if you have power seats)

-HVAC Connections

-Shifter and Boot (if you have a standard, if an automatic, you need to do some research on how to get the selector apart)

-Glove Box including the side panel against the Center Console

-Cigarette Lighter plug

-Driver's Side Knee Bolster

Next, remove the Radio/Head Unit. Disconnect speaker fader switch (if you have the factory Premium Sound, it's the little wheel thingy next to the HU).

The center console is in four separate components, see them here in this diagram: https://www.realoem.com/bmw/enUS/showpa ... Id=51_1096

Separate the HVAC Control Panel and Radio Surround from the Center Console (Part #2) via removing the two small screws you see on the sides. Push the panel through the hole to break the bond. There are four connections holding this whole thing in: 2 small screws in the top of Part #2 which screw into the dashboard (accessed with the HU removed they become exposed), and 2 similar screws that hold the bottom down to the transmission tunnel (you access them through the shifter hole, they go through the clearish plastic bridge).

To remove the Center Console, remove said four screws and begin to carefully lift the rear of the console tilting the whole assembly up. The bond between the top of the Console (Part #2) and the dash might be strong after 30+ years, so it's best to use a plastic trim tool to separate it first. From there rotate it to clear the shifter, dash and parking brake and pull backwards; be sure to feed any cables and wires through holes and around stuff.

The other item that needs to come out is usually the Parking Brake Console. In theory it shouldn't have to since they aren't connected, but they kind of lock together with the Center Console lapping over the PB Console. With it out you have some more room to work in without fear of damaging the PB Console. There are two screws in the back under those flush tabs then another towards the front (can't recall exactly where at the moment).

This gives you clear access to the the HVAC Bowden slider cables connecting to the Control Panel. They are connected via eyelets on the cables that lock onto pins on the sliders then they are snapped into brackets on said sliders. With a little leverage they will easily pop off. Carefully disconnect the bulb holders and fan control plugs that go to the back of the HVAC control panel as it comes out. With all those connections off, you can pull the panel out and bench it for later. This now exposes the HVAC Condenser/Blower Box.

Without stating the obvious, removal is WAY easier and faster than re-installation. Photo everything, label everything and go slow. And be careful.

-

hubble1953

- Posts: 857

- Joined: Dec 25, 2007 1:15 PM

- Location: Boise, Idaho

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Hi Vince: Any news on the m535? It is always a lot of fun to see what you are doing to your car:).

thanks,

jm

thanks,

jm

-

CanadianMiniFan

- Posts: 143

- Joined: Oct 16, 2011 6:31 PM

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Read through this thread over the course of about a week. Bravo Vince, it is rare to see a car refurbished to this level of detail, the zinc plated bolts and fixings really are the finishing touch work like this needs. You started with a car that most people, myself included, would be ecstatic to own, a really nice driver and have taken it to the next level. I hope all your work hasn’t deterred you from using the car, it happens with so many restorations and it’s a shame, so I hope it’s still getting to stretch its legs!

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

hubble1953 wrote: Mar 08, 2023 9:42 PM Hi Vince: Any news on the m535? It is always a lot of fun to see what you are doing to your car:).

thanks,

jm

Update coming soon. I didn't realize how many small projects, punchlist and troubleshooting items I have been doing over the last 12 months.CanadianMiniFan wrote: Mar 17, 2023 12:02 PM ...I hope all your work hasn’t deterred you from using the car, it happens with so many restorations and it’s a shame, so I hope it’s still getting to stretch its legs!

And yes: the urge is strong not to drive this out in the wild as it should be, but I have been trying to make an effort to drive it more and more. It's our winter here and has been raining a lot this year (as I am sure you have been hearing in the news, in fact it's raining and snowing AGAIN this week), so the weather hasn't been so conducive for driving in general let alone getting this car out. But I just returned from our St.Paddy's Day Meet in San Diego this past weekend and put another 400 miles on the odo. Looking ahead to the various events this spring/summer/fall and mapping routes.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

And here it is, or at least the first part of it. Turns out going back and documenting all of what I did is taking some time, so I will split it up into several posts. These are not necessarily in chronological order.

Yes, it has been a while since I updated this thread. And yes, the work has been progressing, although in small degrees. I spent most of 2022 focusing on work (damned annoying that), tackling a punch & troubleshooting list, and just plain enjoying the car. Took the car to some shows and events also: here are some those, there were two others also but undocumented:

June: 2022 BMW Takes Flight, Lyon Air Musem (John Wayne Airport, Irvine, CA):

June: 2022 Huntington Beach Concours:

September: 2022 The Biggest Little 5er Event (aka RenoFest):

November: 2022 SoCal Vintage BMW Meet:

I made mention to the mountain of punch and troubleshooting items I had leftover when I “finished” the interior project in November 2021 (but when is any car project finished, really?). It’s a list I’m still working on, but it is getting smaller. Since I can’t help myself, I have rolled in a series of upgrades and other improvements (it’s the whole “while you’re in there…” scenario) so that list is growing as fast as it is shrinking.

So here is the recap for all that to date:

Most of the items were simple stuff that revolved around just completion and installation, changing a piece/part, final adjusting and the like. Pretty much all of it un-documented but for a list:

-Final Seat Trim & Adjustments:

This was just installing the last of the seat rail covers after I sourced the clips that hold them onto the rails. You can see it here in the is image of the Door Sills (more later on these):

-A/C:

A/C decided not to work at the worst possible time: road trip to Reno in September in the middle of one of the biggest heat waves to hit California. I spent 6-7 grueling hours sweating my b*lls off driving through the Central Valley and into Reno the next day in misery. Went through the litany of possible reasons from major to minor; turns out that all-too-critical relay under the dash was the culprit (the one item I did not change during the whole overhaul ). Sourcing the correct relay (the Behr with the mirrorized label) and replacing it was the solution. I am still keeping an eye on the OEM Condenser since it has a very slow leak. The next step will be a total upgrade with a new aftermarket parallel flow system, but that is likely a ‘next year’ item.

). Sourcing the correct relay (the Behr with the mirrorized label) and replacing it was the solution. I am still keeping an eye on the OEM Condenser since it has a very slow leak. The next step will be a total upgrade with a new aftermarket parallel flow system, but that is likely a ‘next year’ item.

-Lighting:

Had an annoying issue of the headlights turning on and off intermittently while driving, so it was obviously a loose connection somewhere. I don’t normally drive this car in the dark, so the first time I noticed it was during a really early morning drive to a car show last July (the San Marino Classic Concours). Really disconcerting driving down a dark freeway only to have all the lights just magically turn off. The issue was finding the loose connection; I went through every connection on the lights and the harness and through all my separate relays I have controlling the headlights to no avail. Turns out this is also a leftover issue from when I replaced the Fuse Box back in 2016. While the box was new, my wire harnesses were original and many of them had the bad/damaged terminal connectors. The big issue was their inability to lock into the box lid so the relays make strong positive contact. After some investigations, a few of the ones under the low beam relay had dropped back into the box. Now to fix them. I wasn’t easy getting in there as I had to lift the box lid up (the wires kept it from coming up more than a few inches), find the wires, then look at the terminals and see what can be done. On a few of them the locking clip were still intact and with a really tiny pick was able to pull them back into usefulness. A few others no luck; the only solution short of a wire splice (which I should have done when I replaced the box in 2016) was to drop a spot of super glue to hold it in place. I know, not ideal and not the best solution but it works. (I had to do this same thing with a few of the terminals for the wiper relay as they suffered the same problem). This solved the problem, at least for now (of course I haven’t driven at night since then…)

Head Unit & Antenna:

The whole Audio System in this car has been an evolving beast unto itself. It really deserves its’ own entire multi-page, multi-year thread it’s been going on that long. There are so many moving parts in this system, any problems require a lengthy diagnosis process. The issues this time revolved around the Head Unit and the electric Antenna. I replaced the HU in 2021 with a new Continental unit which initially was a good fit into the car: the faceplate style matches the E28 fairly well (at least it’s not overwhelming and garish) with matching colors and easy controls. I swapped this in for the vintage Blaupunkt SQR88 Woodstock I had in before this project. I was having signal and balance issues with it so I wanted to try something different. The issues with the Continental were that the signal connections are via speaker wires only not RCA like the Blaupunkt (well, RCA via a DIN adapter) which meant I had to run a separate set of speaker signal wires in the car (which I did during the project. I had the flash of wisdom to install a set of RCA signal wires also at the same time just in case…). The other issue was after using it for a while, the Continental just didn’t have the range nor the deep sound quality of the Blaupunkt. Also, for whatever the reason, I couldn’t get the Antenna to work with it as I would have needed a special adapter to fit the Hirschmann connector. So, I went back to the Blaupunkt with improved connections which seems to have fixed most of the previous issues. Sounds so much better than before and the Continental (and is period correct for the E28). I’m still having issues with the Amp Board overheating in the trunk which is focus of an entire sub-project to address this and upgrade some of the system components (new sub-woofer speakers and control chips in the Processor). I just got back from a road trip to San Diego for the 2023 St.Paddy's Day Meet and can attest to how sonically wonderful this system is when it's working. Even at freeway speeds I still can't listen to it past level 4 on the volume. Oh, but what a joy it is.

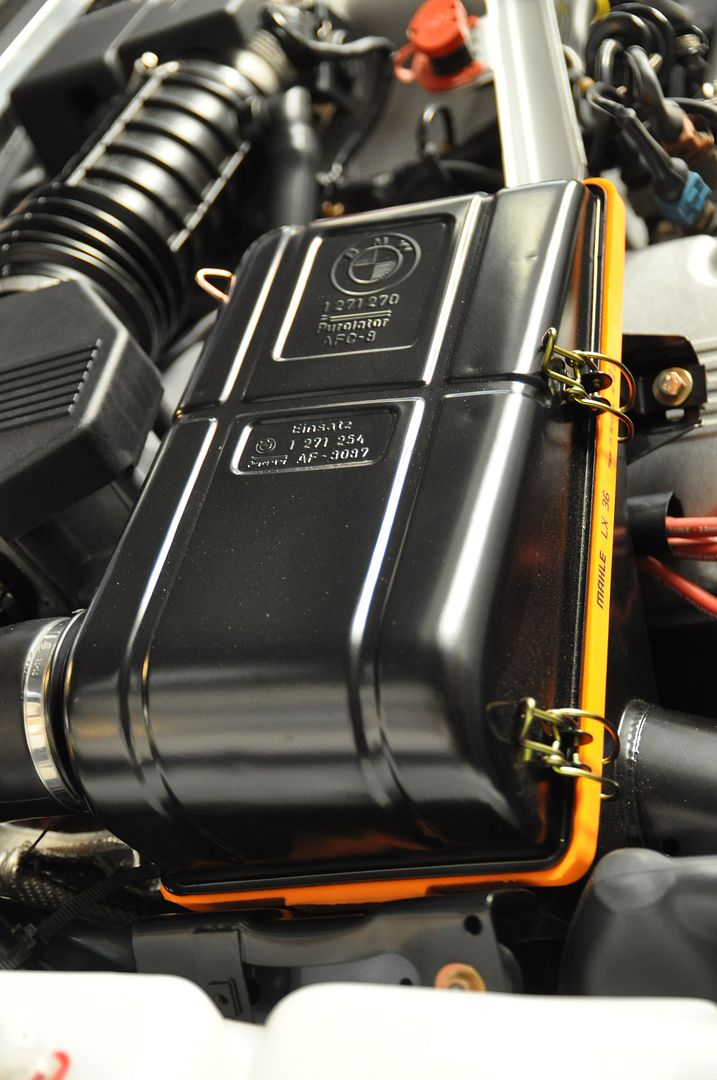

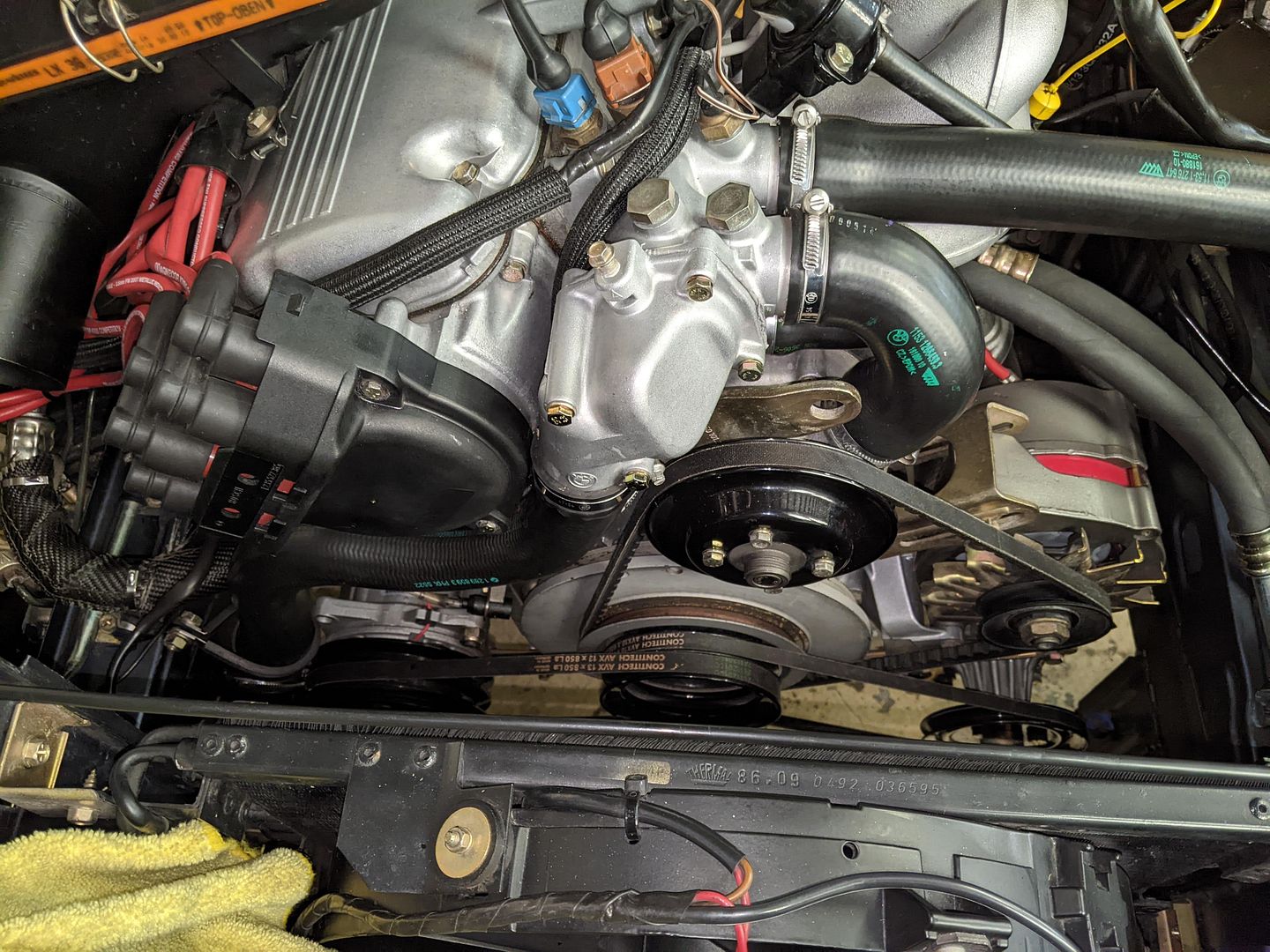

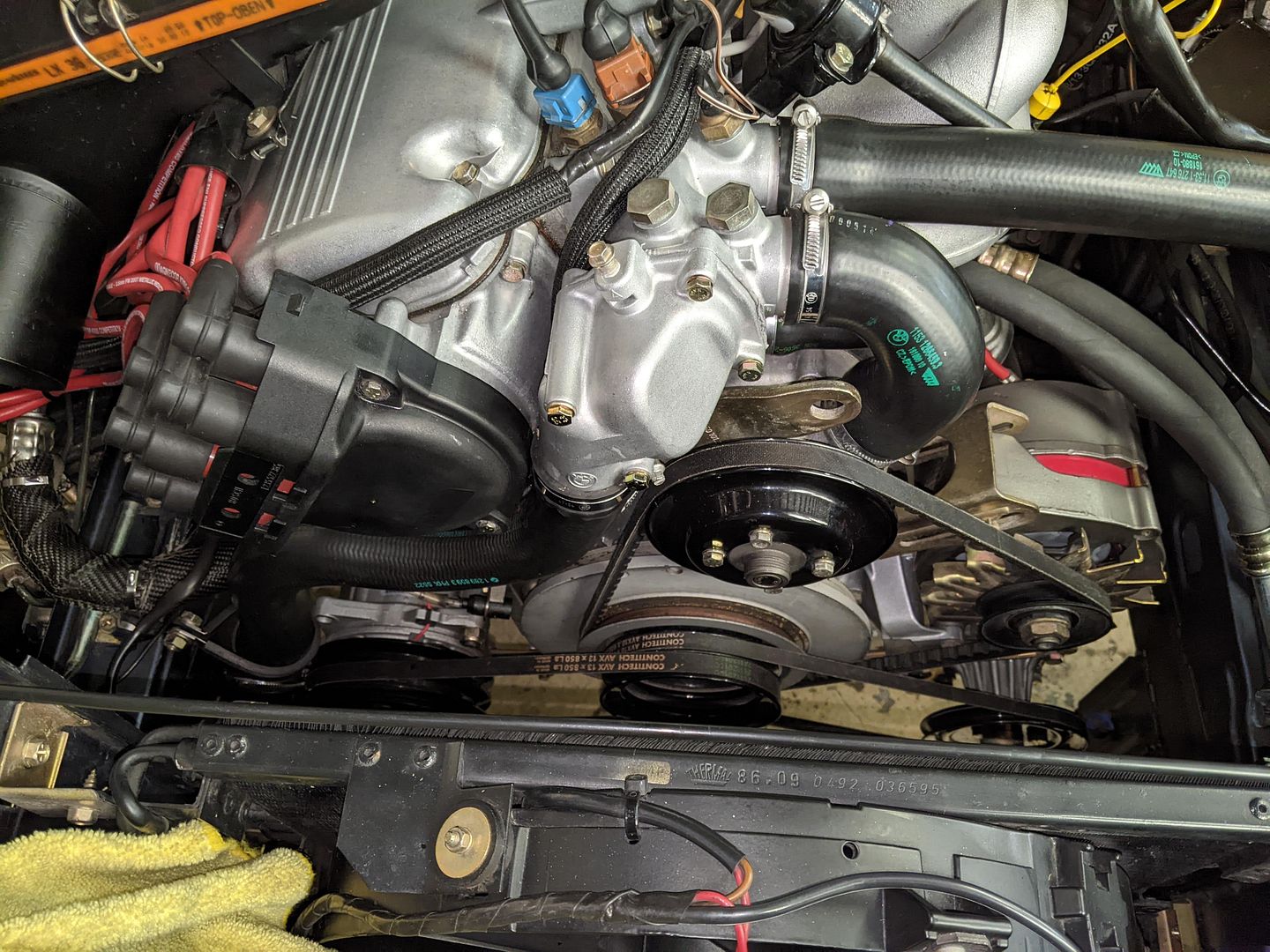

Air Filter Box Restoration:

Long time back, I tried my hand at applying a 'crinkle' finish to the cover of my Air Filter Box. I had been meaning to fully complete the engine bay work and repaint that, but it fell low on the priority list. I finally got around to dropping it off to a powdercoater nearby and had them do their magic.

More soon...

Yes, it has been a while since I updated this thread. And yes, the work has been progressing, although in small degrees. I spent most of 2022 focusing on work (damned annoying that), tackling a punch & troubleshooting list, and just plain enjoying the car. Took the car to some shows and events also: here are some those, there were two others also but undocumented:

June: 2022 BMW Takes Flight, Lyon Air Musem (John Wayne Airport, Irvine, CA):

June: 2022 Huntington Beach Concours:

September: 2022 The Biggest Little 5er Event (aka RenoFest):

November: 2022 SoCal Vintage BMW Meet:

I made mention to the mountain of punch and troubleshooting items I had leftover when I “finished” the interior project in November 2021 (but when is any car project finished, really?). It’s a list I’m still working on, but it is getting smaller. Since I can’t help myself, I have rolled in a series of upgrades and other improvements (it’s the whole “while you’re in there…” scenario) so that list is growing as fast as it is shrinking.

So here is the recap for all that to date:

Most of the items were simple stuff that revolved around just completion and installation, changing a piece/part, final adjusting and the like. Pretty much all of it un-documented but for a list:

-Final Seat Trim & Adjustments:

This was just installing the last of the seat rail covers after I sourced the clips that hold them onto the rails. You can see it here in the is image of the Door Sills (more later on these):

-A/C:

A/C decided not to work at the worst possible time: road trip to Reno in September in the middle of one of the biggest heat waves to hit California. I spent 6-7 grueling hours sweating my b*lls off driving through the Central Valley and into Reno the next day in misery. Went through the litany of possible reasons from major to minor; turns out that all-too-critical relay under the dash was the culprit (the one item I did not change during the whole overhaul

-Lighting:

Had an annoying issue of the headlights turning on and off intermittently while driving, so it was obviously a loose connection somewhere. I don’t normally drive this car in the dark, so the first time I noticed it was during a really early morning drive to a car show last July (the San Marino Classic Concours). Really disconcerting driving down a dark freeway only to have all the lights just magically turn off. The issue was finding the loose connection; I went through every connection on the lights and the harness and through all my separate relays I have controlling the headlights to no avail. Turns out this is also a leftover issue from when I replaced the Fuse Box back in 2016. While the box was new, my wire harnesses were original and many of them had the bad/damaged terminal connectors. The big issue was their inability to lock into the box lid so the relays make strong positive contact. After some investigations, a few of the ones under the low beam relay had dropped back into the box. Now to fix them. I wasn’t easy getting in there as I had to lift the box lid up (the wires kept it from coming up more than a few inches), find the wires, then look at the terminals and see what can be done. On a few of them the locking clip were still intact and with a really tiny pick was able to pull them back into usefulness. A few others no luck; the only solution short of a wire splice (which I should have done when I replaced the box in 2016) was to drop a spot of super glue to hold it in place. I know, not ideal and not the best solution but it works. (I had to do this same thing with a few of the terminals for the wiper relay as they suffered the same problem). This solved the problem, at least for now (of course I haven’t driven at night since then…)

Head Unit & Antenna:

The whole Audio System in this car has been an evolving beast unto itself. It really deserves its’ own entire multi-page, multi-year thread it’s been going on that long. There are so many moving parts in this system, any problems require a lengthy diagnosis process. The issues this time revolved around the Head Unit and the electric Antenna. I replaced the HU in 2021 with a new Continental unit which initially was a good fit into the car: the faceplate style matches the E28 fairly well (at least it’s not overwhelming and garish) with matching colors and easy controls. I swapped this in for the vintage Blaupunkt SQR88 Woodstock I had in before this project. I was having signal and balance issues with it so I wanted to try something different. The issues with the Continental were that the signal connections are via speaker wires only not RCA like the Blaupunkt (well, RCA via a DIN adapter) which meant I had to run a separate set of speaker signal wires in the car (which I did during the project. I had the flash of wisdom to install a set of RCA signal wires also at the same time just in case…). The other issue was after using it for a while, the Continental just didn’t have the range nor the deep sound quality of the Blaupunkt. Also, for whatever the reason, I couldn’t get the Antenna to work with it as I would have needed a special adapter to fit the Hirschmann connector. So, I went back to the Blaupunkt with improved connections which seems to have fixed most of the previous issues. Sounds so much better than before and the Continental (and is period correct for the E28). I’m still having issues with the Amp Board overheating in the trunk which is focus of an entire sub-project to address this and upgrade some of the system components (new sub-woofer speakers and control chips in the Processor). I just got back from a road trip to San Diego for the 2023 St.Paddy's Day Meet and can attest to how sonically wonderful this system is when it's working. Even at freeway speeds I still can't listen to it past level 4 on the volume. Oh, but what a joy it is.

Air Filter Box Restoration:

Long time back, I tried my hand at applying a 'crinkle' finish to the cover of my Air Filter Box. I had been meaning to fully complete the engine bay work and repaint that, but it fell low on the priority list. I finally got around to dropping it off to a powdercoater nearby and had them do their magic.

More soon...

Last edited by vinceg101 on Mar 27, 2023 9:20 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Thanks for the update. Do you mind sharing which Continental head unit you discarded? I ask because I am on the fence about purchasing this one:

https://www.continental-automotive.com/ ... -Bluetooth

I like the way it looks, the matching amber lighting, and the fact that it has a CD player and Bluetooth. If the sound suffers, however, I'll pass.

https://www.continental-automotive.com/ ... -Bluetooth

I like the way it looks, the matching amber lighting, and the fact that it has a CD player and Bluetooth. If the sound suffers, however, I'll pass.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

It was the TR7411, the real bottom of the line version without CD or BT.Mdreamer wrote: Mar 20, 2023 11:50 PM Thanks for the update. Do you mind sharing which Continental head unit you discarded? I ask because I am on the fence about purchasing this one:

https://www.continental-automotive.com/ ... -Bluetooth

I like the way it looks, the matching amber lighting, and the fact that it has a CD player and Bluetooth. If the sound suffers, however, I'll pass.

I wouldn't say it sounded bad, it just wasn't as 'deep' as older headunits if that makes any sense. The low end was a little light and maybe the midrange was soft as well. And I was pushing it through a dual amped a/d/s/, 6 speaker setup so I'm not sure what it would sound like on its' own.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

To expand on that, while I'm no expert on Continental or any modern HU, I can't imagine that whomever makes these made them with any significant change regarding their internal circuitry. Meaning, that while my experience was with the bottom model, I believe that by adding a CD player and BT would not necessarily change the audio EQ in the output nor radio; they only thing it adds are the chips or programming for those two extra devices/inputs. So while you have additional interfaces and sources in their higher decks, it doesn't mean it sounds any better or is capable of higher quality sound.

My opinion only, could be wrong.

My opinion only, could be wrong.

Last edited by vinceg101 on Mar 27, 2023 9:21 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Some more...

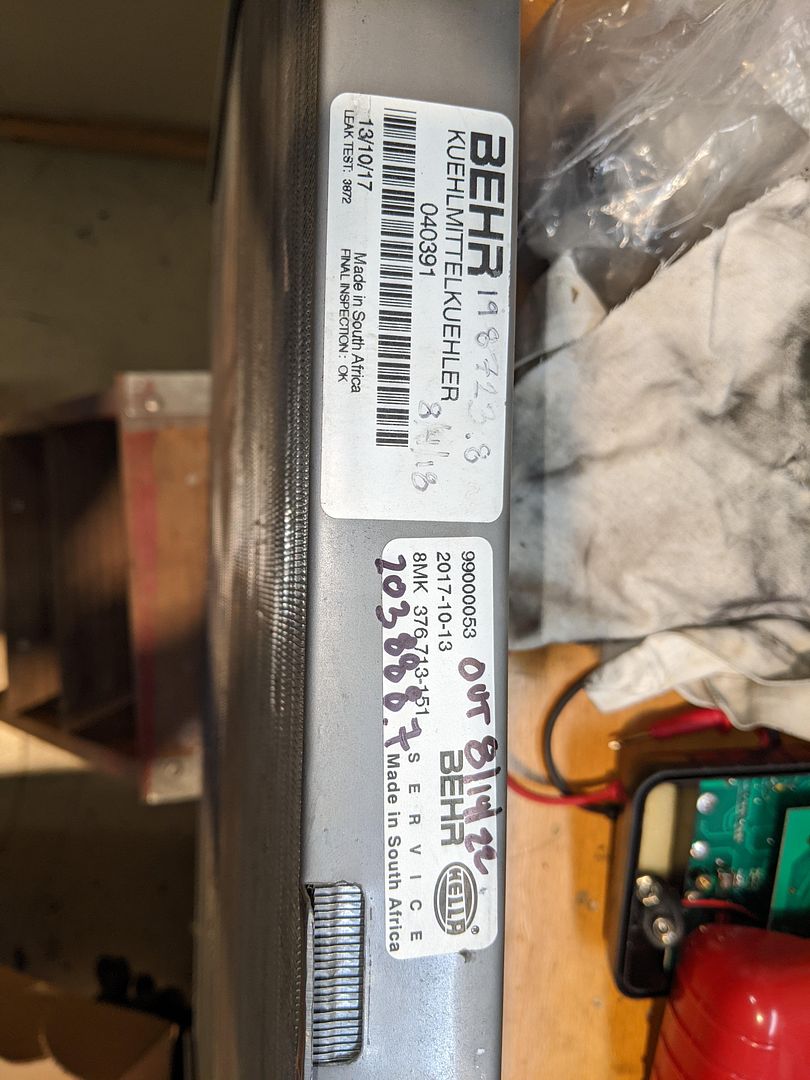

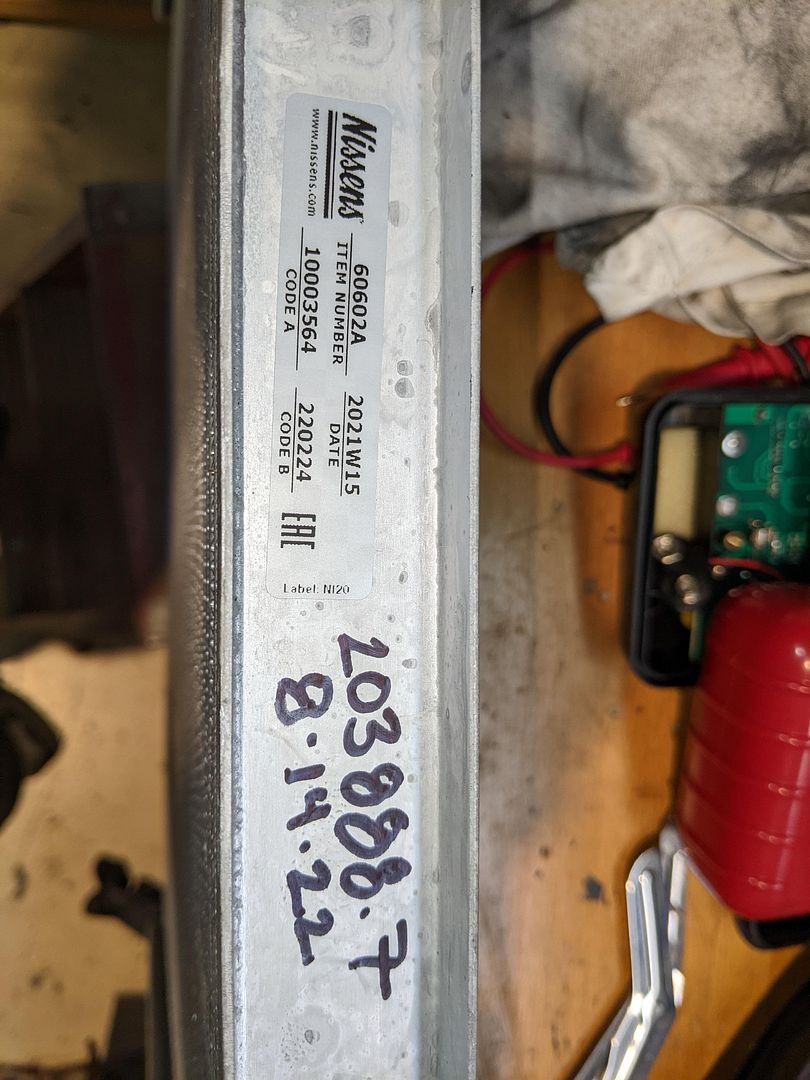

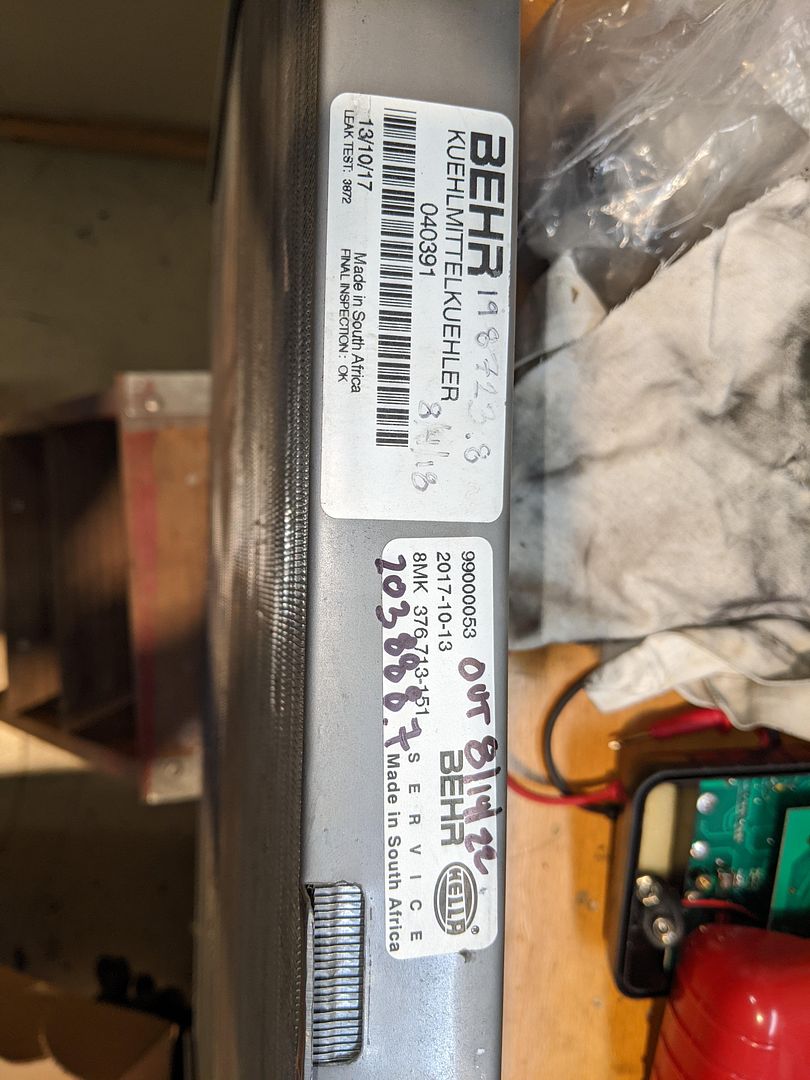

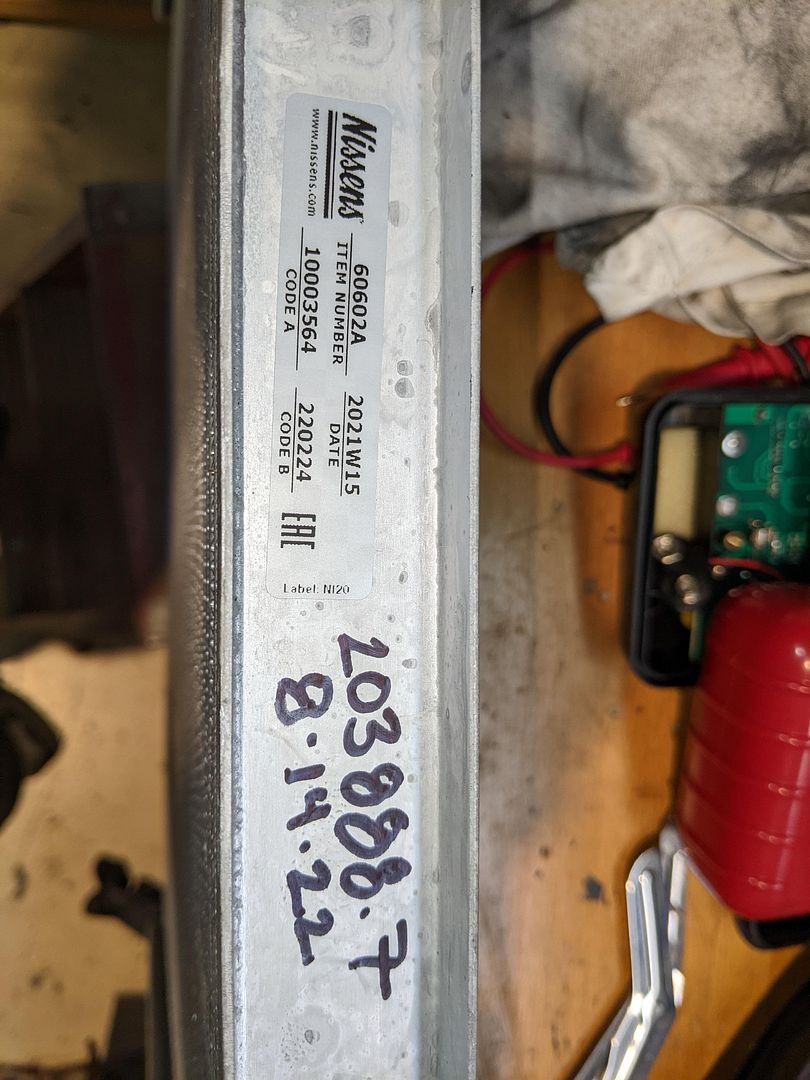

Cooling System:

This is was a carryover from the big project and the troubleshooting items then. I had been having issues with erratic and higher than ‘normal’ (normal from this cars’ past performance) mostly under strain and load. If you look through my threads in the past you will find the issues I had with South African Behr Radiator replacements and their failures (new out of the box). Turns out the SA Behrs underwent an internal design change in their cooling tubes and chambers that results in weaker performance. For the longest time, the SA Behr’s were superior to Nissens but not anymore. (Oddly, the OEM BMW unit, also made by Behr but under the older designs, still are superior but at a premium cost.)

I also decided to revert back to the colder Thermostat; this may result in slightly poorer fuel economy but it’s a favorable trade-off in my mind since I don’t drive this car that often (not that it got great MPG before). I replaced both and am holding new sensors in reserve to see if they need to get replaced also, but so far not necessary.

The good news is that during that drive in September in the 100’s over prolonged driving, the engine temps were right at 3/8’-1/2 and rock steady even going up grades.

Door Latch Adjustments:

I replaced all the Door Strikes (the ones on the body) during the Interior project with new ones. I was originally going to just replate them (which I ended up doing anyway) but it was actually cheaper just to buy new ones. I replaced them but could never get the final adjustments done in order to completely cinch the doors closed. It is a frustrating process of back and forth, micro adjustments; the solution is kind of counterintuitive that in end, by my own humble & embarrassing admittance, was accomplished by someone else (thank you wkohler; he schooled me and did it in under 5 minutes ).

).

Body Repairs: Lower Rockers:

Okay, so this doesn’t really have any documentation to go with this but it was a major deal that needed to happen. Going all the way back to the Exterior Body Work section of the Front End Overhaul portion of this thread, you will remember that when I removed the M-Tech Side Skirts I discovered rust and rot at the rear jack points and Lower Rocker Panels. Due to timing with Doug’s shop and his schedule back in 2021, I opted to wait to tackle these later. Last July was later. In short he cut out of the cancerous sections and spliced in grafts I got from a donor car years ago. Then he repainted the Lower Rockers and pretty sure he did the whole Side Skirts also. (Which reminds me I have to install the double-stick tape on these for a complete installation. I am kind of waiting to execute another ‘upgrade’ project which repairing/replacing the forward frame rails damaged by careless jacking).

Here are the offending 'before' photos (sorry no 'after' at the moment as I would have to remove the Side Skirts to expose it all). Suffice it say, it's all been repaired and re-painted now:

Cooling System:

This is was a carryover from the big project and the troubleshooting items then. I had been having issues with erratic and higher than ‘normal’ (normal from this cars’ past performance) mostly under strain and load. If you look through my threads in the past you will find the issues I had with South African Behr Radiator replacements and their failures (new out of the box). Turns out the SA Behrs underwent an internal design change in their cooling tubes and chambers that results in weaker performance. For the longest time, the SA Behr’s were superior to Nissens but not anymore. (Oddly, the OEM BMW unit, also made by Behr but under the older designs, still are superior but at a premium cost.)

I also decided to revert back to the colder Thermostat; this may result in slightly poorer fuel economy but it’s a favorable trade-off in my mind since I don’t drive this car that often (not that it got great MPG before). I replaced both and am holding new sensors in reserve to see if they need to get replaced also, but so far not necessary.

The good news is that during that drive in September in the 100’s over prolonged driving, the engine temps were right at 3/8’-1/2 and rock steady even going up grades.

Door Latch Adjustments:

I replaced all the Door Strikes (the ones on the body) during the Interior project with new ones. I was originally going to just replate them (which I ended up doing anyway) but it was actually cheaper just to buy new ones. I replaced them but could never get the final adjustments done in order to completely cinch the doors closed. It is a frustrating process of back and forth, micro adjustments; the solution is kind of counterintuitive that in end, by my own humble & embarrassing admittance, was accomplished by someone else (thank you wkohler; he schooled me and did it in under 5 minutes

Body Repairs: Lower Rockers:

Okay, so this doesn’t really have any documentation to go with this but it was a major deal that needed to happen. Going all the way back to the Exterior Body Work section of the Front End Overhaul portion of this thread, you will remember that when I removed the M-Tech Side Skirts I discovered rust and rot at the rear jack points and Lower Rocker Panels. Due to timing with Doug’s shop and his schedule back in 2021, I opted to wait to tackle these later. Last July was later. In short he cut out of the cancerous sections and spliced in grafts I got from a donor car years ago. Then he repainted the Lower Rockers and pretty sure he did the whole Side Skirts also. (Which reminds me I have to install the double-stick tape on these for a complete installation. I am kind of waiting to execute another ‘upgrade’ project which repairing/replacing the forward frame rails damaged by careless jacking).

Here are the offending 'before' photos (sorry no 'after' at the moment as I would have to remove the Side Skirts to expose it all). Suffice it say, it's all been repaired and re-painted now:

Last edited by vinceg101 on Mar 27, 2023 9:07 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Next...

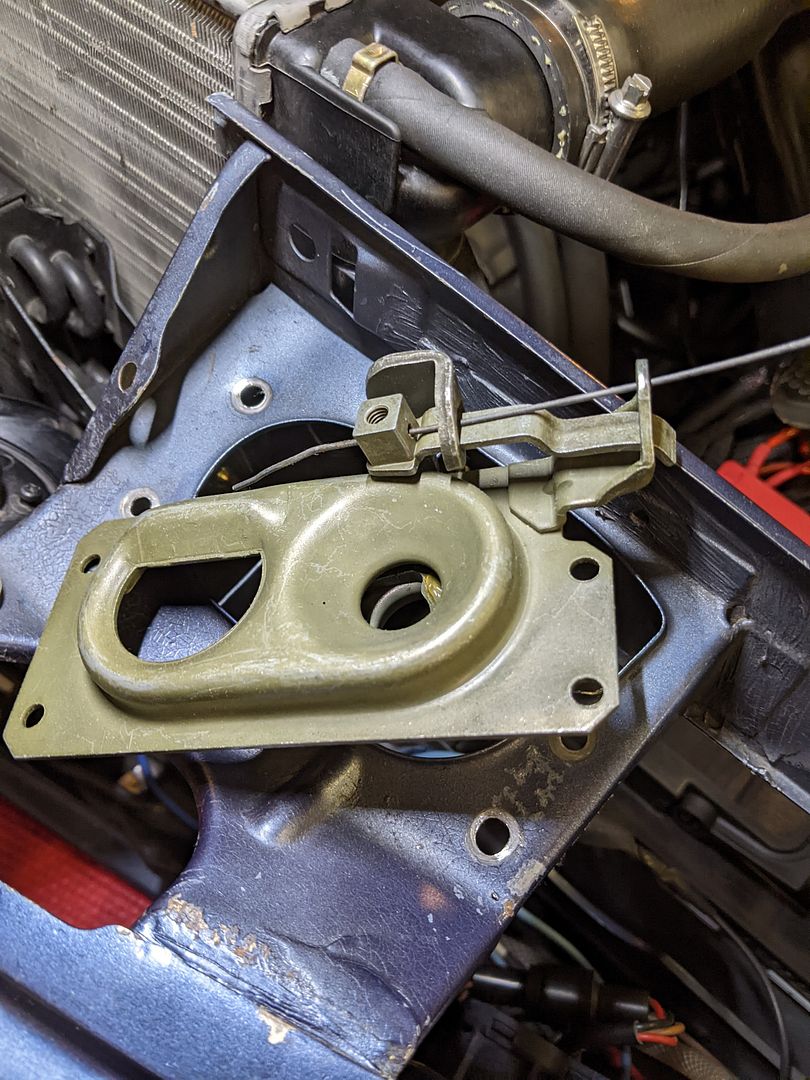

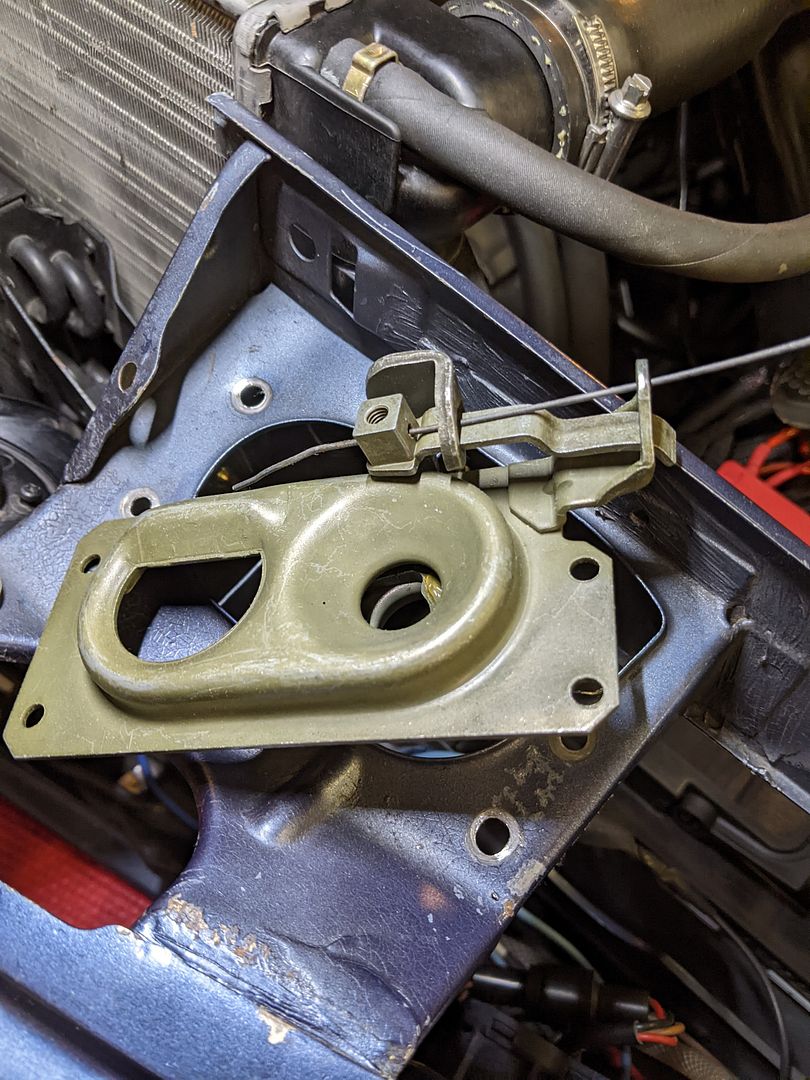

Hood Latches:

This was to correct a mistake/misstep I did back in 2016 wherein I re-plated them in yellow zinc. They are supposed to be a form of Green Cad, a finish that is very hard for modern platers to match (at least the ones I know around here). At the time (early 2022) all four components were still available from BMW, so that’s what I did.

-First I had to remove the previous yellow zinc versions which means I had to drill out the four pop-rivets holding the base receptors onto the front nose. Be sure to put down copious amounts of towels or cardboard to catch all the metal filings and the spent rivets (they go everywhere). In fact magnets would help a lot.

-Installation: Feed the release cable through the driver’s side and then across the top of the radiator shroud/nose over the passenger’s side. It doesn’t really matter which side you start to install first, just be sure you need to feed the release cable through the driver’s side receiver catch first.

-Be sure you pick up or borrow a good quality HD rivet gun since the BMW rivets are steel not aluminum. Steel is needed since these are under a fair amount of force and tension. If you’re using a hand-powered version get ready for a workout. You might also have to grind off or file off any messy cut tabs (in theory you shouldn’t have to with a quality tool as it should snap off the legs cleanly; mine didn’t). You want to be careful if you do grind/file them off so as not to scuff the rivet heads too much as they are very visible (if that matters to you).

-Make the final release cable connections into the receiver latches and install with the proper yellow zinc M6 set bolt. Test the cabin release lever then tighten the bolts down. (There should be a visible indentation on the cable from where the connection was before, so start there.)

-Next install the upper catches on the hood itself. Again, there should be marks on the hood where the old catches were so start here. The holes are cut with a slight oval for adjustments particularly the driver’s side with the release handle. You should also note the amount of threads on the bolt under the springs are showing on the old ones since this is you starting point for the hood seating. Adjustments are straight-forward: loosen the locking nut at the base, use large regular screwdriver to rotate the bolt and spring up/down or in/out. If you’re doing this from scratch, it will take some back and forth (opening/closing of the hood) to find the right position for these. Same for the horizontal positions of the latches on the hood. Slightly tedious but should be okay if you’re starting at the old positions. I believe this process is spelled out in the Bentley's. You can get the official BMW bolts with integrated washers or you can pick up correct yellow zinc hardware somewhere for the four bolts holding both sides to the hood.

-That’s it. Clean up, make one final check for latching and safety catching and hood seating. Be sure to apply any additional grease in the receivers catches (they come with some from the factory but you may need more). There are two plastic cover caps that slide onto the bottom of the receivers on the nose; be sure to install these before the headlights as it's easier access. Close it all up and you’re done.

[I know, one of these days I may have the whole radiator support/nose repainted. It's original and wasn't repainted with the rest of the car back in 1990/91. It's looking a bit tattered.]

Hood Latches:

This was to correct a mistake/misstep I did back in 2016 wherein I re-plated them in yellow zinc. They are supposed to be a form of Green Cad, a finish that is very hard for modern platers to match (at least the ones I know around here). At the time (early 2022) all four components were still available from BMW, so that’s what I did.

-First I had to remove the previous yellow zinc versions which means I had to drill out the four pop-rivets holding the base receptors onto the front nose. Be sure to put down copious amounts of towels or cardboard to catch all the metal filings and the spent rivets (they go everywhere). In fact magnets would help a lot.

-Installation: Feed the release cable through the driver’s side and then across the top of the radiator shroud/nose over the passenger’s side. It doesn’t really matter which side you start to install first, just be sure you need to feed the release cable through the driver’s side receiver catch first.

-Be sure you pick up or borrow a good quality HD rivet gun since the BMW rivets are steel not aluminum. Steel is needed since these are under a fair amount of force and tension. If you’re using a hand-powered version get ready for a workout. You might also have to grind off or file off any messy cut tabs (in theory you shouldn’t have to with a quality tool as it should snap off the legs cleanly; mine didn’t). You want to be careful if you do grind/file them off so as not to scuff the rivet heads too much as they are very visible (if that matters to you).

-Make the final release cable connections into the receiver latches and install with the proper yellow zinc M6 set bolt. Test the cabin release lever then tighten the bolts down. (There should be a visible indentation on the cable from where the connection was before, so start there.)

-Next install the upper catches on the hood itself. Again, there should be marks on the hood where the old catches were so start here. The holes are cut with a slight oval for adjustments particularly the driver’s side with the release handle. You should also note the amount of threads on the bolt under the springs are showing on the old ones since this is you starting point for the hood seating. Adjustments are straight-forward: loosen the locking nut at the base, use large regular screwdriver to rotate the bolt and spring up/down or in/out. If you’re doing this from scratch, it will take some back and forth (opening/closing of the hood) to find the right position for these. Same for the horizontal positions of the latches on the hood. Slightly tedious but should be okay if you’re starting at the old positions. I believe this process is spelled out in the Bentley's. You can get the official BMW bolts with integrated washers or you can pick up correct yellow zinc hardware somewhere for the four bolts holding both sides to the hood.

-That’s it. Clean up, make one final check for latching and safety catching and hood seating. Be sure to apply any additional grease in the receivers catches (they come with some from the factory but you may need more). There are two plastic cover caps that slide onto the bottom of the receivers on the nose; be sure to install these before the headlights as it's easier access. Close it all up and you’re done.

[I know, one of these days I may have the whole radiator support/nose repainted. It's original and wasn't repainted with the rest of the car back in 1990/91. It's looking a bit tattered.]

Last edited by vinceg101 on Mar 27, 2023 9:12 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Progression

I love this car.

Re: 1985 Arktisblau M535i Renovation - Progression

UPDATE

Wow, has it really been almost a year since my last update? Yikes, apologies for not keeping up. I went back and realized that I had drafted one to follow last March's but I never completed it and posted it.

Not much happened during 2023 but for some small projects, both troubleshooting/repairs and some upgrades. The first part of the below list took place back in 2022 with the remainder up until just recently. I have to promise myself to make this more of a regular thing since waiting a year or so to update is daunting and time consuming (I'm just as soon to skip updating altogether, but I said to myself I wouldn't do that).

Okay so here we go:

2022:

BBS Wheel Refinishing:

This was one of those items that should have been a low priority items since my BBS RS211’s were still in relatively good condition. There were some blemishes that I couldn’t get out and the wheel bolts were corroded or at least were losing their sharpness. So, I set out on what I thought would and should have been a straightforward task. I had done this exercise for my spare wheel the previous summer, so it should have been simple. On the spare wheel it was a combined effort between the wheel refinishing shop and the plating shop for the bolts.

Through a bit of bad luck on timing & schedules between the two shops and my own, sourcing a replacement set of BBS wheel rim bolts and the wheel refinisher going out of business in the middle of the whole thing, the task turned complicated and took waaay longer than anticipated. A mistake by the first wheel refinisher (the wrong center color and not finding out until the day they closed their doors) forced me to find another shop and more or less start all over again. The only thing they really didn’t have to do was polish the lips again, but they had to do everything else which included dismantling the three piece BBS system, remove the glue, strip the paint on the centers, find the matching paint (a sort of bronze/pewter), then reassemble them all. So, in the end I paid a lot of money to effectively have my lips polished. Add in a new set of Continental’s since the old set was aging out (certainly not by tread wear) and this turned into a major investment, more than I was anticipating for something that was more or less optional.

On and on it went from there. But in the end, they came out good looking much better than they were before.

Windshield Wiper System:

My wiper motor has been progressively slowing down for years now and all the stuff under the cowling was showing its’ age (not that I ever drive this car in the rain, but hey, it’s about the principle, right?) This was a splurge and maybe in getting older I made an executive decision to use the hardest working tool in my toolbox: my credit card. I opted to buy all new parts rather than trying to refinish/rebuild the motor and other parts since it was all still available (except a few hardware pieces). Given BMW’s penchant to discontinue parts at will, there was no telling if they would be available in the near/far future. So, an order was placed and I waiting for the Norwegian express to deliver a box.

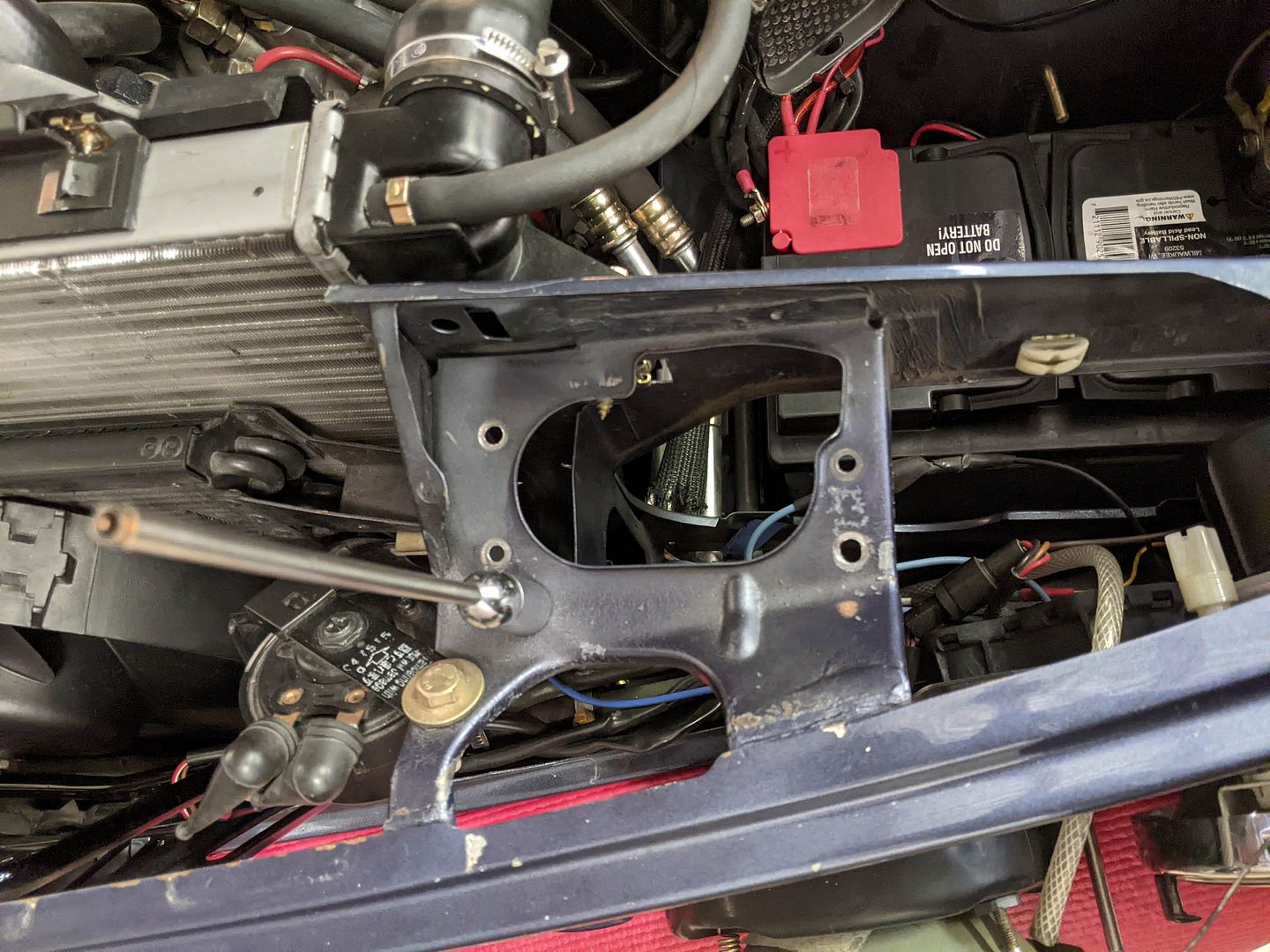

First up: Removal:

1) Remove the firewall panel in the engine bay to access the system

2) Next, remove the Wiper Arms but first pulling up the plastic covering cap on the Wiper Arm

3) Then pull up the plastic covering over to expose the Retaining Nut

4) Next unbolt the thin Retaining Nuts & washers. Important to note here: these two Retaining Nuts actually secure the whole Wiper Arm and motor to the body. There is a small rubber adjuster ‘foot’ behind the motor that braces it to the inner well firewall, but otherwise, that’s it.

5) The rubber gasket ring that goes around the hole in the outer body cowling has likely decomposed over time (mine had) so you may have to carefully pick and pull it out of the hole. Clean up with some cleaner (Goof-Off or a little lacquer thinner) to get the residue off.

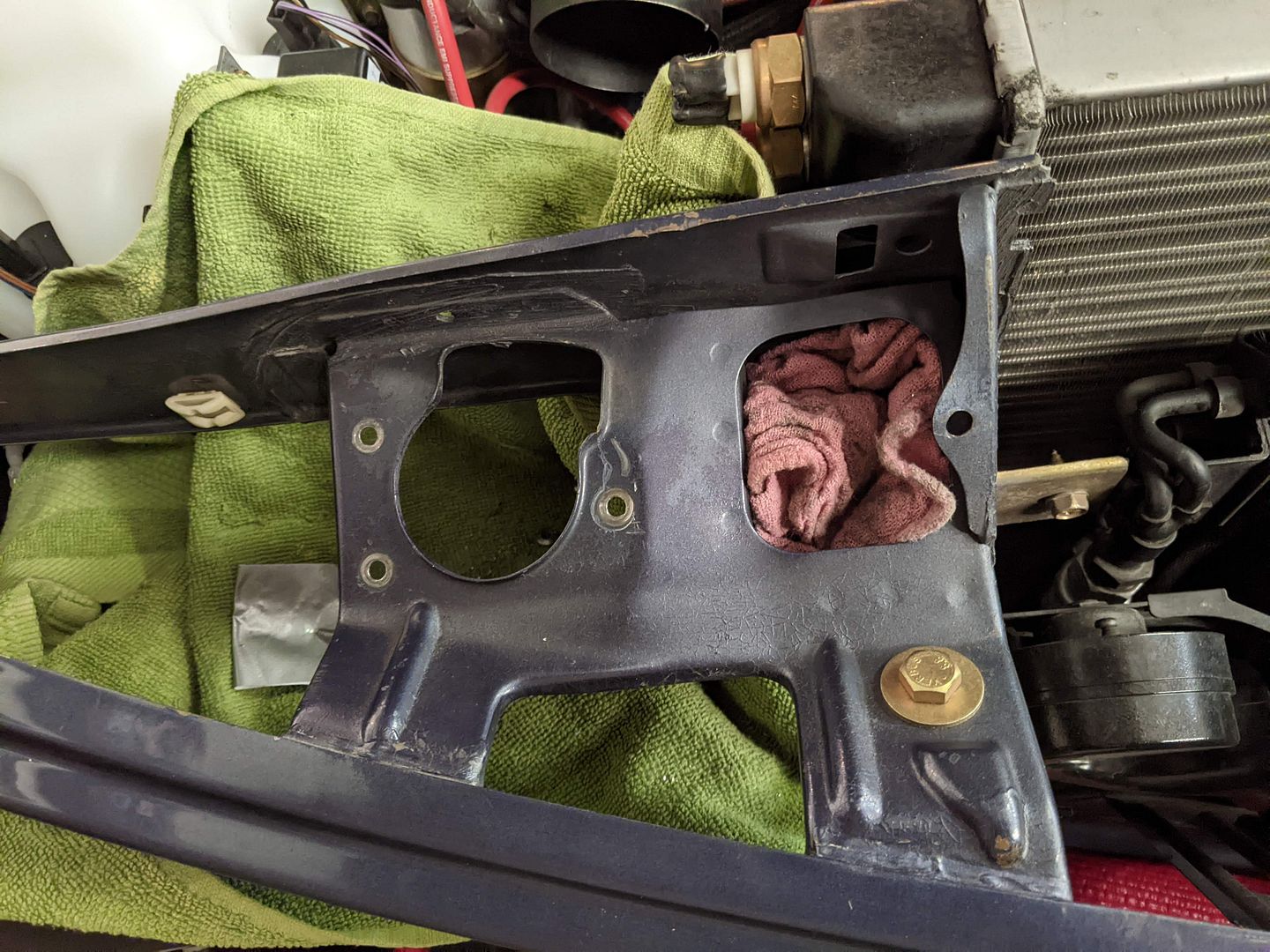

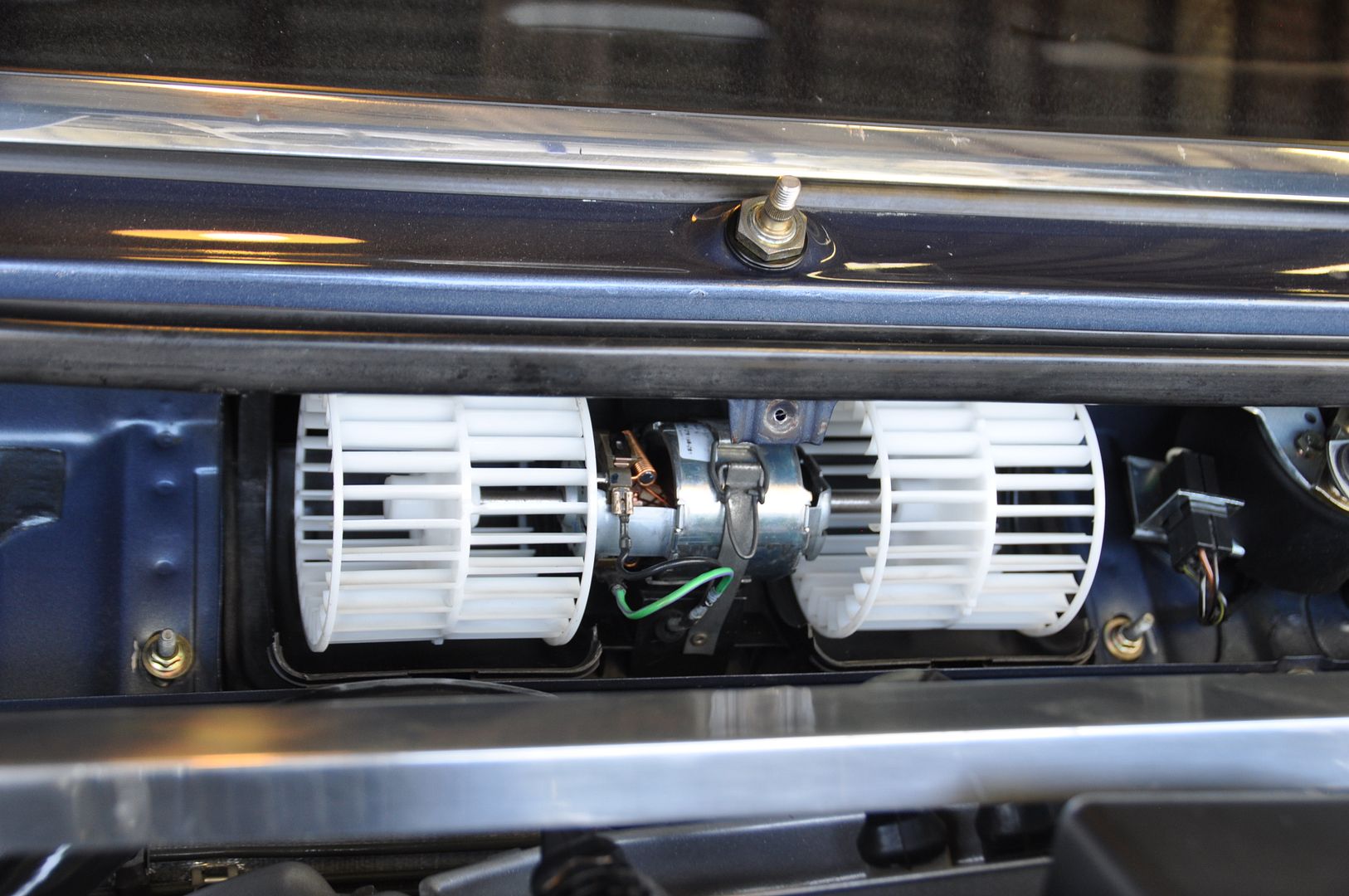

6) Remove the Fresh Air Blower Fan Covers and Fan itself (now’s the time to replace it if it needs it)

7) Disconnect the Wiper Motor power plug

8) Unbolt & remove the Wiper Motor from the Wiper Arm: there are three smaller nuts holding the Motor to the underside of the Arm and the one nut that connects the Motor to the rotating Arm joint in the center

9) Now comes the tricky part: Pull the Motor out from below while keeping the Arm secure in place (it might help to reinstall the two Retaining Nuts to hold it to the cowling). With the Motor out of the way, you can drop the Wiper Arm down into the well as the Wiper Arm connections drop through the cowling holes. From there, you have to rotate the armature flat to clear the firewall well. Don’t mar your paint.

Now is a great time to clean the whole well thoroughly. Vacuum, wash, dry. Clean out the drain holes and inspect for any rust. If all is good, liberally apply some wax and treat the Fresh Air Fan holder and cover as well as the Wipe Motor plastic cover.

Next: Prep & Install the New Parts:

1) Sort out the mounting hardware. The one item that is NLA is the thin Retaining Nut that holds the Wiper Arm securely to the cowling; keep your existing and/or source some new (I found what I thought was a thin replacement nut, but it was too thick and that matters since you can’t fit the covers back on. So, stick with the original part)

2) I opted to spray the Wiper Arm assembly with a clear spray lacquer to help keep the aluminum looking fresh and from oxidizing

3) Install the new rubber gasket/grommets in the cowling holes

Installation is the reverse of disassembly. Careful to slide the New Wiper Motor into the well first, then install the Wiper Arm. It’s best to secure the Wiper Arm up into the cowling holes first before trying to mount the Wiper Motor; this way one of the items is stable. With them in place, adjust the rubber leveling ‘foot’ so it makes contact with the back of the firewall. Secure the Retaining Nuts to the cowling, reconnect the power plug and you’re ready to move onto Wiper Arms. Remember to reinstall the Fresh Air Fan and its’ cover.

This is where most everyone will just reinstall the arms and covers, but not me. Not willing to let well enough alone, I just had to address the next two components to serve my anal nature.

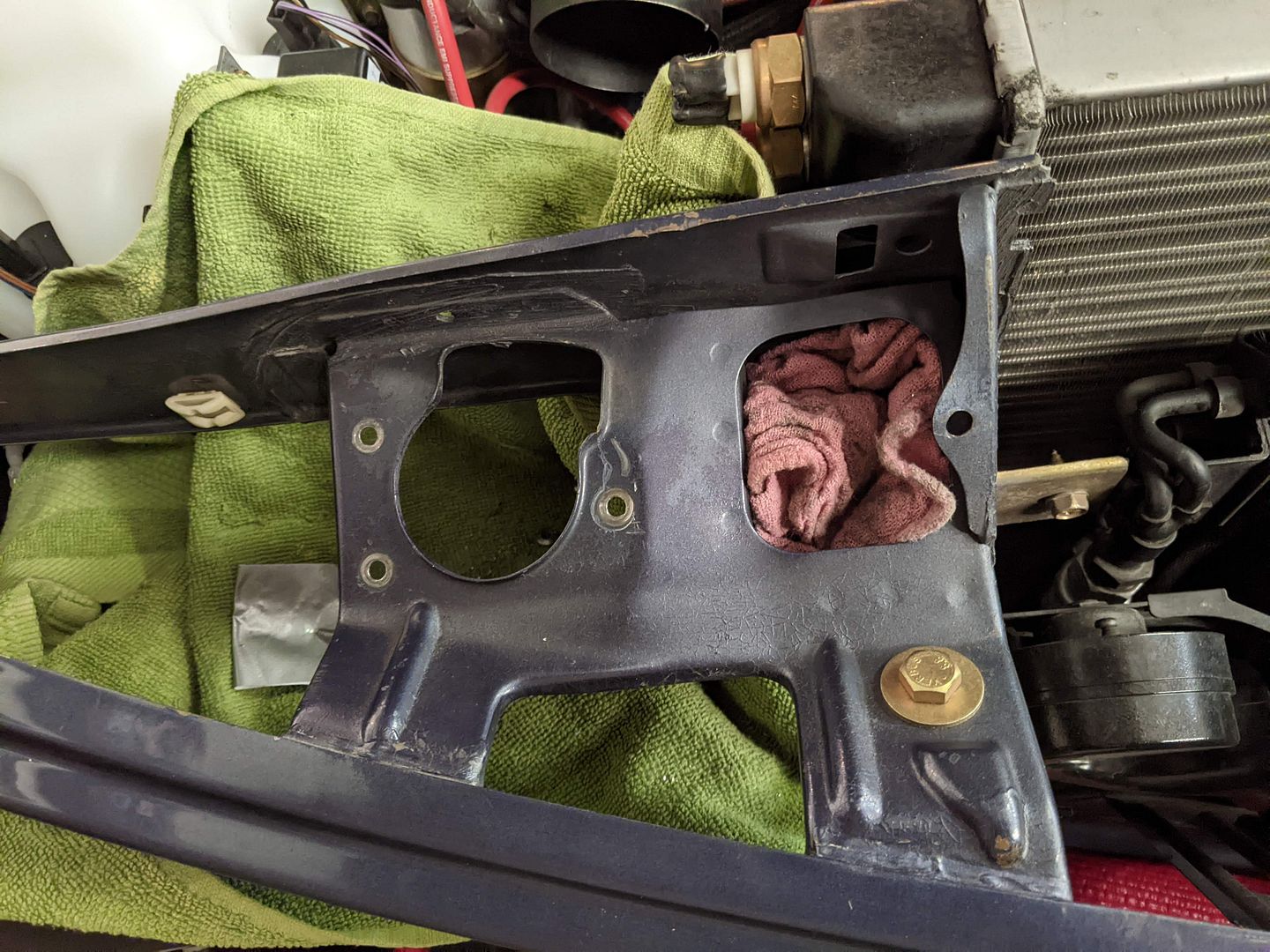

Firewall Cover Panel:

Mine was in remarkably good condition for being original, and seeing as how these are also NLA, I had to work with what I had. The engine side rubber/neoprene coating was mostly intact so there wasn’t much to do to that side except treat it thoroughly with a rubber preservative. What did need addressing was new foam gasketing on the backside facing the Wiper Arm well.

1) Remove the old existing deteriorating gasket, scrape off the residue, and clean

2) When done, the whole back side needed repainting, so I sanded it all down and prepped for new paint

3) Applied a few coats of Rustoleum Satin Black (since there was some surface rust and didn’t want that coming back)

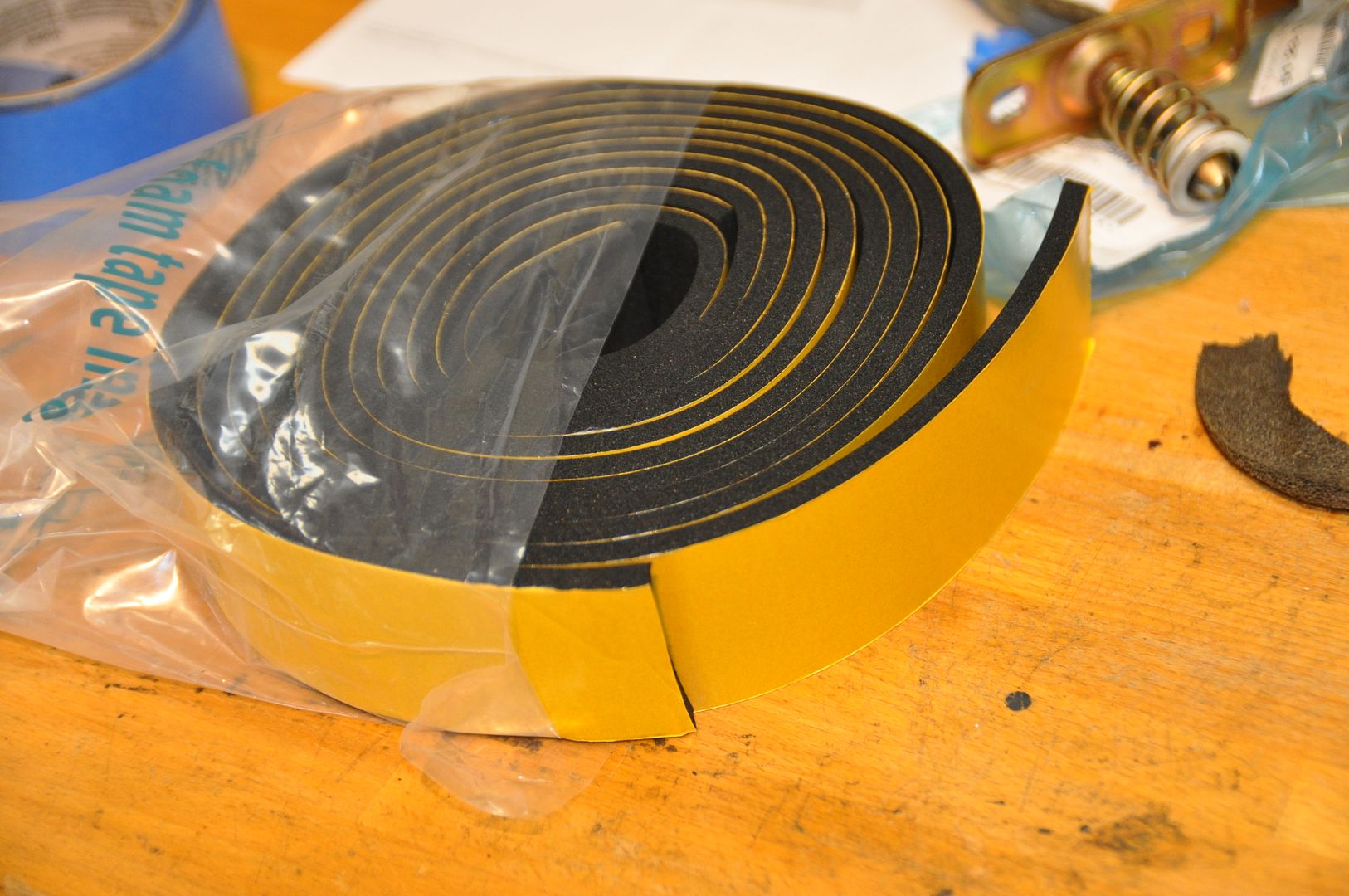

4) I sourced some replacement foam gasket tape in the right thickness and width and set out to template the pieces. This is closed-cell vs. the open cell foam BMW used. I prefer the closed-cell for its' compressiblity and its' ability to seal better

5) Installed the new foam gasketing. Final fitting and re-installation (after testing and final Wiper Arms adjustments)

Wiper Arms:

Here again E28 Wiper Arms are now all NLA, so we all have to work with what we’ve got. Finding replacements (the correct ones) in decent condition is very hard these days. I was lucky in that I had one NIB US E28 (late) Passenger Arm in a box, but I had to refinish my Driver’s side with the high-speed wing (I think it is actually either an E24 or E32 version, but I don’t know). What’s worse is repainting old ones is actually hard (especially if you’re relying on spray can paints); I imagine if you’re using a spray gun it might yield better results. I did several spare arms at the same time. First up:

Prep & Paint:

The old ones were pitted and scratched from road wear with a little bit of rust. So I bench wire-wheeled them all down to as much bare metal as possible. Then I sanded these as smooth as I could.

2) I applied a few coats of self-leveling automotive primer to even out the surface as much as possible; wait for this to thoroughly set up and dry (like a week if possible)

3) Start applying fine,light coats of SEM Black Trim paint (although that doesn’t completely match the finish of the original Wiper Arms as they are glossier). Be careful with the paint and make it go on evenly; I kept having to go back and remove paint and re-apply as it kept splattering or running (here a paint sprayer would have helped). Again, set them up to thoroughly cure and dry (a week)

4) To address the finish issues, I applied a very light coat of clear spray lacquer to both try to match the OEM finish as well give them some protection. And again, let them cure completely (yes, another week)

Wiper Arm Installation:

Install your favorite flavor of blades and mount them to Wiper Arm bolts with the small nuts & washers. Pretty straight-forward but follow instincts and the Bentley manual for aligning & adjusting. Once you have them set, lock in the top nuts, install the covers and close everything up.

Wow, has it really been almost a year since my last update? Yikes, apologies for not keeping up. I went back and realized that I had drafted one to follow last March's but I never completed it and posted it.

Not much happened during 2023 but for some small projects, both troubleshooting/repairs and some upgrades. The first part of the below list took place back in 2022 with the remainder up until just recently. I have to promise myself to make this more of a regular thing since waiting a year or so to update is daunting and time consuming (I'm just as soon to skip updating altogether, but I said to myself I wouldn't do that).

Okay so here we go:

2022:

BBS Wheel Refinishing:

This was one of those items that should have been a low priority items since my BBS RS211’s were still in relatively good condition. There were some blemishes that I couldn’t get out and the wheel bolts were corroded or at least were losing their sharpness. So, I set out on what I thought would and should have been a straightforward task. I had done this exercise for my spare wheel the previous summer, so it should have been simple. On the spare wheel it was a combined effort between the wheel refinishing shop and the plating shop for the bolts.

Through a bit of bad luck on timing & schedules between the two shops and my own, sourcing a replacement set of BBS wheel rim bolts and the wheel refinisher going out of business in the middle of the whole thing, the task turned complicated and took waaay longer than anticipated. A mistake by the first wheel refinisher (the wrong center color and not finding out until the day they closed their doors) forced me to find another shop and more or less start all over again. The only thing they really didn’t have to do was polish the lips again, but they had to do everything else which included dismantling the three piece BBS system, remove the glue, strip the paint on the centers, find the matching paint (a sort of bronze/pewter), then reassemble them all. So, in the end I paid a lot of money to effectively have my lips polished. Add in a new set of Continental’s since the old set was aging out (certainly not by tread wear) and this turned into a major investment, more than I was anticipating for something that was more or less optional.

On and on it went from there. But in the end, they came out good looking much better than they were before.

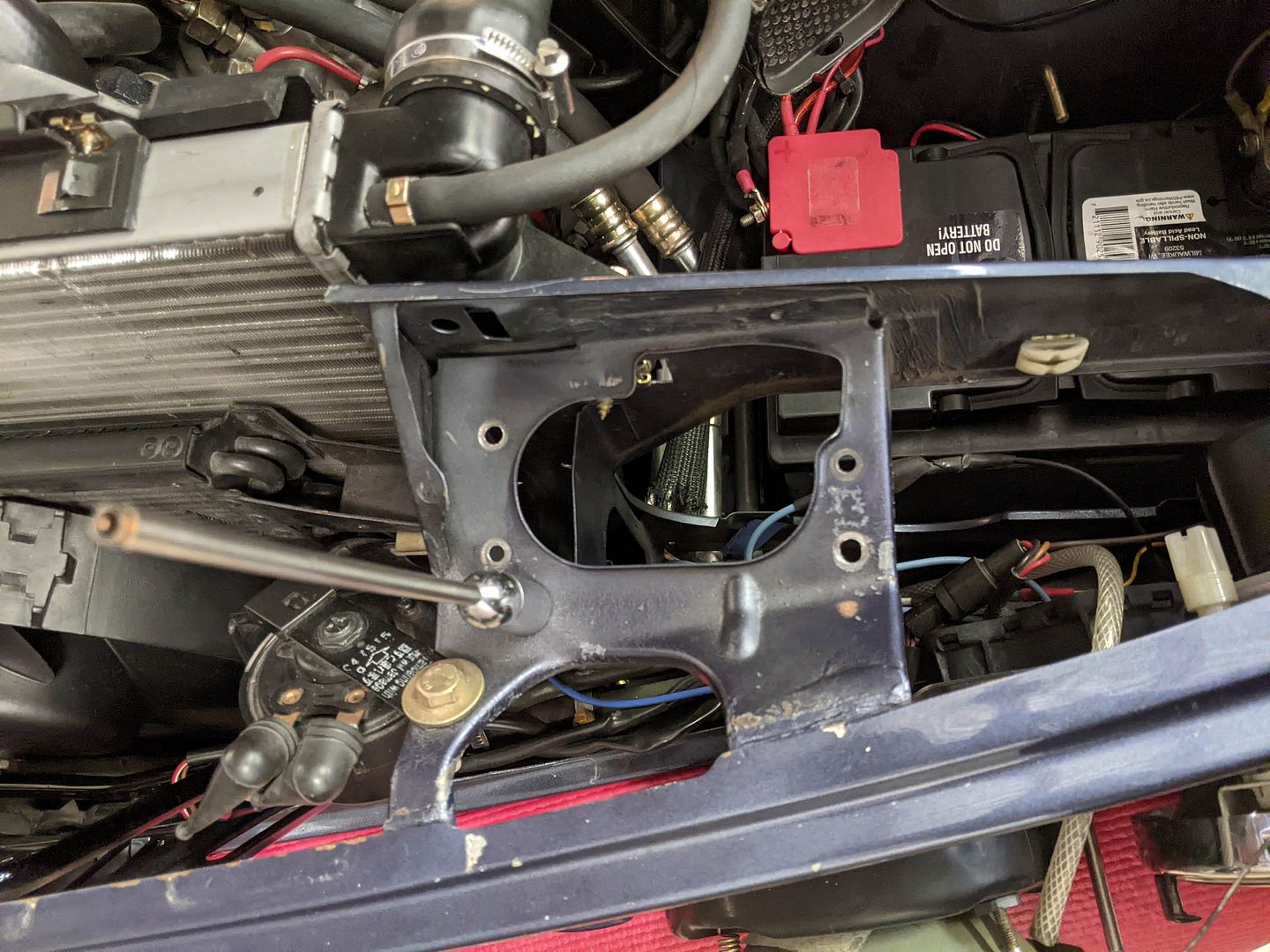

Windshield Wiper System:

My wiper motor has been progressively slowing down for years now and all the stuff under the cowling was showing its’ age (not that I ever drive this car in the rain, but hey, it’s about the principle, right?) This was a splurge and maybe in getting older I made an executive decision to use the hardest working tool in my toolbox: my credit card. I opted to buy all new parts rather than trying to refinish/rebuild the motor and other parts since it was all still available (except a few hardware pieces). Given BMW’s penchant to discontinue parts at will, there was no telling if they would be available in the near/far future. So, an order was placed and I waiting for the Norwegian express to deliver a box.

First up: Removal:

1) Remove the firewall panel in the engine bay to access the system

2) Next, remove the Wiper Arms but first pulling up the plastic covering cap on the Wiper Arm

3) Then pull up the plastic covering over to expose the Retaining Nut

4) Next unbolt the thin Retaining Nuts & washers. Important to note here: these two Retaining Nuts actually secure the whole Wiper Arm and motor to the body. There is a small rubber adjuster ‘foot’ behind the motor that braces it to the inner well firewall, but otherwise, that’s it.

5) The rubber gasket ring that goes around the hole in the outer body cowling has likely decomposed over time (mine had) so you may have to carefully pick and pull it out of the hole. Clean up with some cleaner (Goof-Off or a little lacquer thinner) to get the residue off.

6) Remove the Fresh Air Blower Fan Covers and Fan itself (now’s the time to replace it if it needs it)

7) Disconnect the Wiper Motor power plug

8) Unbolt & remove the Wiper Motor from the Wiper Arm: there are three smaller nuts holding the Motor to the underside of the Arm and the one nut that connects the Motor to the rotating Arm joint in the center

9) Now comes the tricky part: Pull the Motor out from below while keeping the Arm secure in place (it might help to reinstall the two Retaining Nuts to hold it to the cowling). With the Motor out of the way, you can drop the Wiper Arm down into the well as the Wiper Arm connections drop through the cowling holes. From there, you have to rotate the armature flat to clear the firewall well. Don’t mar your paint.

Now is a great time to clean the whole well thoroughly. Vacuum, wash, dry. Clean out the drain holes and inspect for any rust. If all is good, liberally apply some wax and treat the Fresh Air Fan holder and cover as well as the Wipe Motor plastic cover.

Next: Prep & Install the New Parts:

1) Sort out the mounting hardware. The one item that is NLA is the thin Retaining Nut that holds the Wiper Arm securely to the cowling; keep your existing and/or source some new (I found what I thought was a thin replacement nut, but it was too thick and that matters since you can’t fit the covers back on. So, stick with the original part)

2) I opted to spray the Wiper Arm assembly with a clear spray lacquer to help keep the aluminum looking fresh and from oxidizing

3) Install the new rubber gasket/grommets in the cowling holes

Installation is the reverse of disassembly. Careful to slide the New Wiper Motor into the well first, then install the Wiper Arm. It’s best to secure the Wiper Arm up into the cowling holes first before trying to mount the Wiper Motor; this way one of the items is stable. With them in place, adjust the rubber leveling ‘foot’ so it makes contact with the back of the firewall. Secure the Retaining Nuts to the cowling, reconnect the power plug and you’re ready to move onto Wiper Arms. Remember to reinstall the Fresh Air Fan and its’ cover.

This is where most everyone will just reinstall the arms and covers, but not me. Not willing to let well enough alone, I just had to address the next two components to serve my anal nature.

Firewall Cover Panel:

Mine was in remarkably good condition for being original, and seeing as how these are also NLA, I had to work with what I had. The engine side rubber/neoprene coating was mostly intact so there wasn’t much to do to that side except treat it thoroughly with a rubber preservative. What did need addressing was new foam gasketing on the backside facing the Wiper Arm well.

1) Remove the old existing deteriorating gasket, scrape off the residue, and clean

2) When done, the whole back side needed repainting, so I sanded it all down and prepped for new paint

3) Applied a few coats of Rustoleum Satin Black (since there was some surface rust and didn’t want that coming back)

4) I sourced some replacement foam gasket tape in the right thickness and width and set out to template the pieces. This is closed-cell vs. the open cell foam BMW used. I prefer the closed-cell for its' compressiblity and its' ability to seal better

5) Installed the new foam gasketing. Final fitting and re-installation (after testing and final Wiper Arms adjustments)

Wiper Arms:

Here again E28 Wiper Arms are now all NLA, so we all have to work with what we’ve got. Finding replacements (the correct ones) in decent condition is very hard these days. I was lucky in that I had one NIB US E28 (late) Passenger Arm in a box, but I had to refinish my Driver’s side with the high-speed wing (I think it is actually either an E24 or E32 version, but I don’t know). What’s worse is repainting old ones is actually hard (especially if you’re relying on spray can paints); I imagine if you’re using a spray gun it might yield better results. I did several spare arms at the same time. First up:

Prep & Paint:

The old ones were pitted and scratched from road wear with a little bit of rust. So I bench wire-wheeled them all down to as much bare metal as possible. Then I sanded these as smooth as I could.

2) I applied a few coats of self-leveling automotive primer to even out the surface as much as possible; wait for this to thoroughly set up and dry (like a week if possible)

3) Start applying fine,light coats of SEM Black Trim paint (although that doesn’t completely match the finish of the original Wiper Arms as they are glossier). Be careful with the paint and make it go on evenly; I kept having to go back and remove paint and re-apply as it kept splattering or running (here a paint sprayer would have helped). Again, set them up to thoroughly cure and dry (a week)

4) To address the finish issues, I applied a very light coat of clear spray lacquer to both try to match the OEM finish as well give them some protection. And again, let them cure completely (yes, another week)

Wiper Arm Installation:

Install your favorite flavor of blades and mount them to Wiper Arm bolts with the small nuts & washers. Pretty straight-forward but follow instincts and the Bentley manual for aligning & adjusting. Once you have them set, lock in the top nuts, install the covers and close everything up.